Preparation method of surface micro and nano composite structure of monocrystalline cell

A composite structure, micro-nano technology, applied in chemical instruments and methods, circuits, crystal growth, etc., can solve the problem of reducing the photoelectric conversion efficiency of single crystal silicon cells, increasing the surface recombination of minority carriers, and limiting the high specific surface area. Problems such as fleece effect, to achieve low reflectivity, reduce surface compounding, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

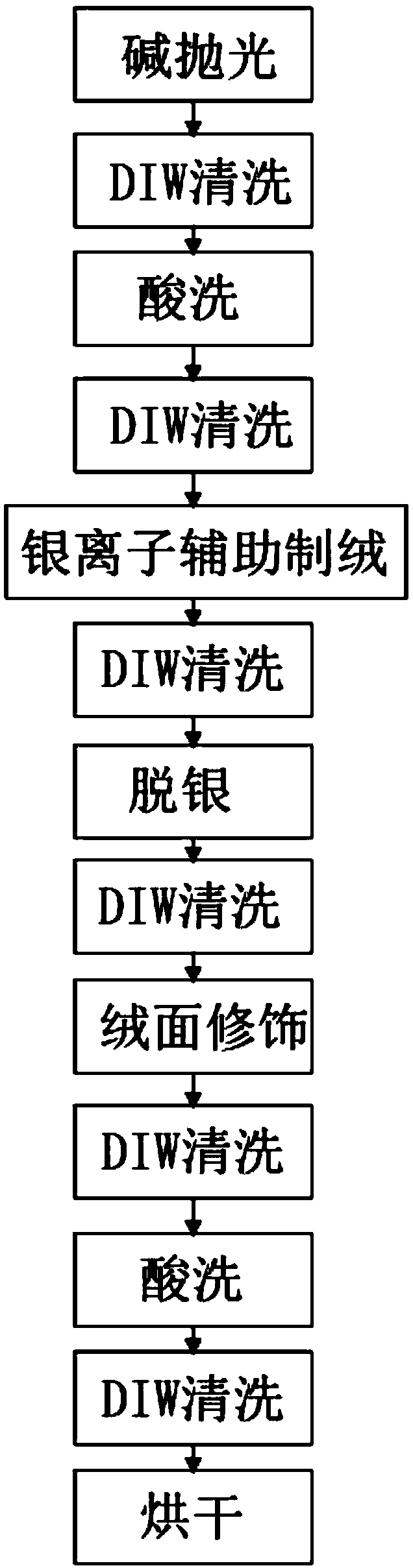

[0028] A method for preparing a surface micro-nano composite structure of a single crystal cell, as shown in the attached Figure 5 shown, including the following steps:

[0029] S1. Alkali texturing: use alkali texturing solution to texturize monocrystalline cells. The alkali texturing solution is a mixed solution of NaOH, additives and DIW. The additives are commonly used texturing additives. The concentration of NaOH is 7%, the additive concentration is 0.5%, the temperature is controlled at 83°C, and the reaction time is 12min. Image 6 As shown, a pyramid suede surface with a reflectivity of 15% is formed, and the pyramid size is 5 μm;

[0030] Perform a DIW wash.

[0031] S2. Pickling 1: pickling with HNO3 solution, the concentration of the HNO3 solution is 0.5%, the temperature is controlled at normal temperature, and the pickling time is 60s;

[0032] Perform a DIW wash.

[0033] S3. Silver ion-assisted texturing: use an auxiliary texturing solution to perform text...

Embodiment 2

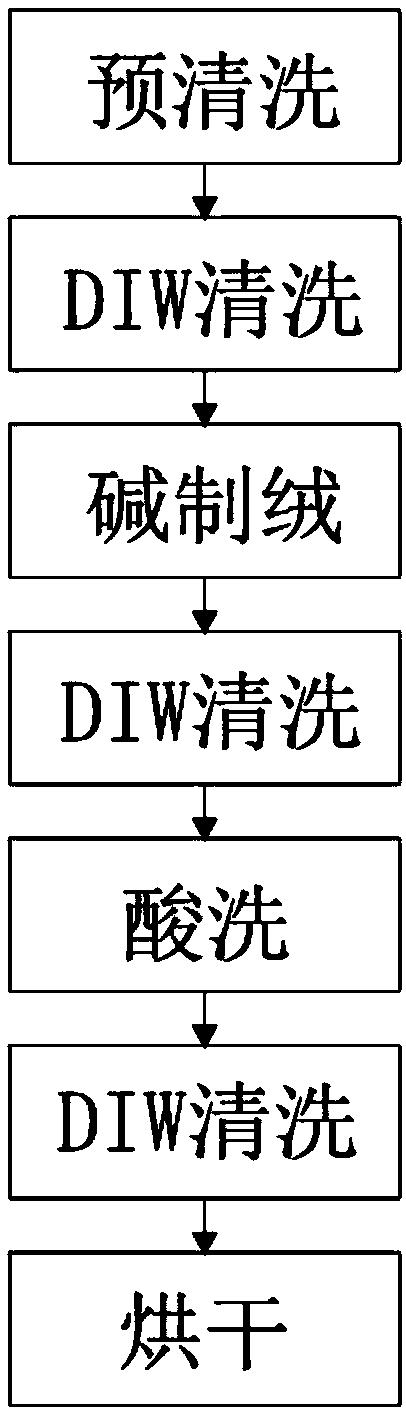

[0043] A method for preparing a surface micro-nano composite structure of a single crystal cell, comprising the following steps:

[0044] S1. Alkali texturing: use an alkali texturing solution to perform texturing on single crystal cells. The alkali texturing solution is a mixed solution of NaOH, additives and DIW, wherein the concentration of NaOH is 9%, and the concentration of additives is 1%. The temperature is controlled at 87°C, and the reaction time is 15 minutes to form a pyramid suede surface with a reflectivity of 17%, and the pyramid size is 10 μm;

[0045] Perform a DIW wash.

[0046] S2. Pickling 1: pickling with HNO3 solution, the concentration of the HNO3 solution is 1%, the temperature is controlled at normal temperature, and the pickling time is 100s;

[0047] Perform a DIW wash.

[0048] S3. Silver ion-assisted texturing: use an auxiliary texturing solution to perform texturing on single crystal cells, and the auxiliary texturing solution is a mixed solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap