A voltage parameter detection device of a motor driver and the motor driver

A motor driver and voltage parameter technology, applied in the direction of motor parameter estimation/correction, etc., can solve problems such as common cause failure, low precision of motor driver torque control, and inability to sample variable rationality verification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

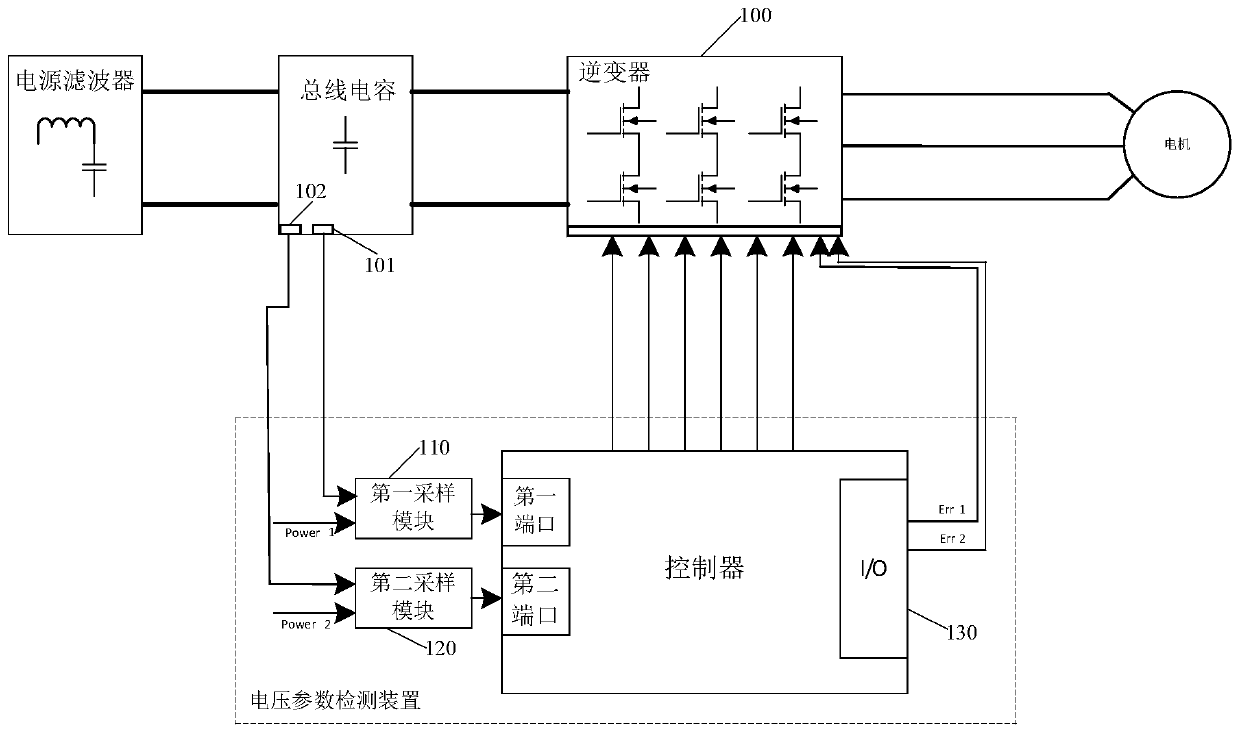

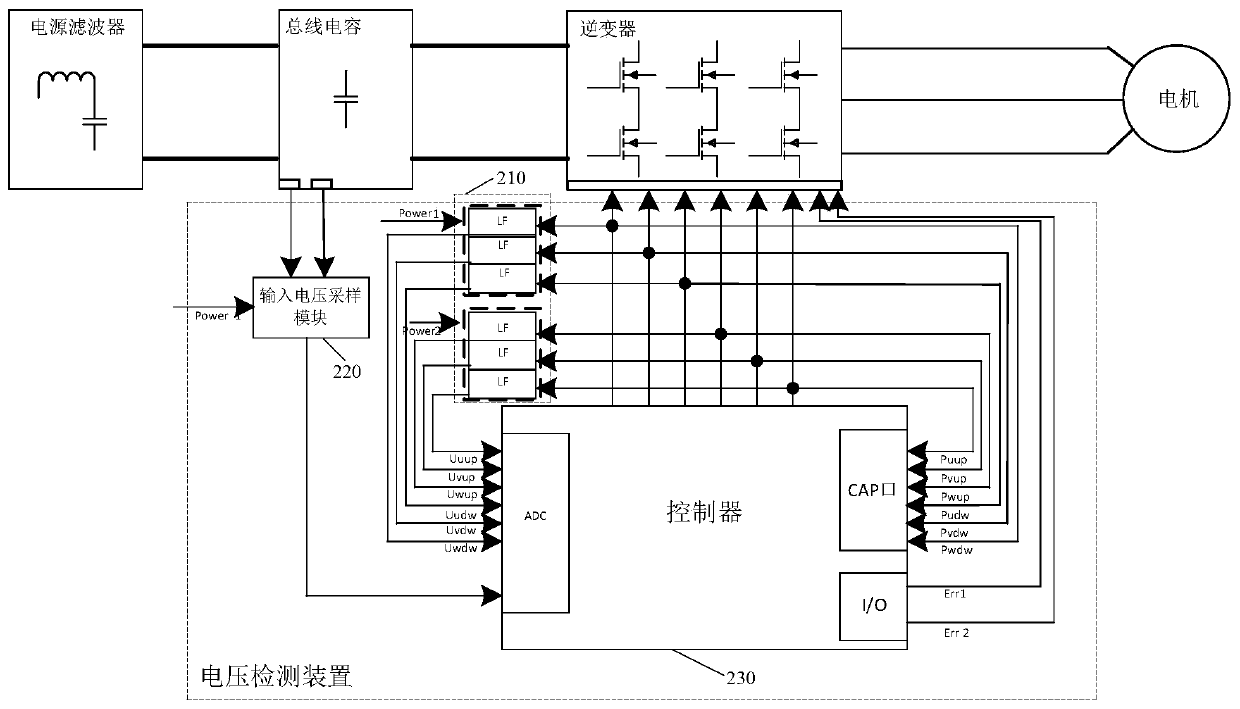

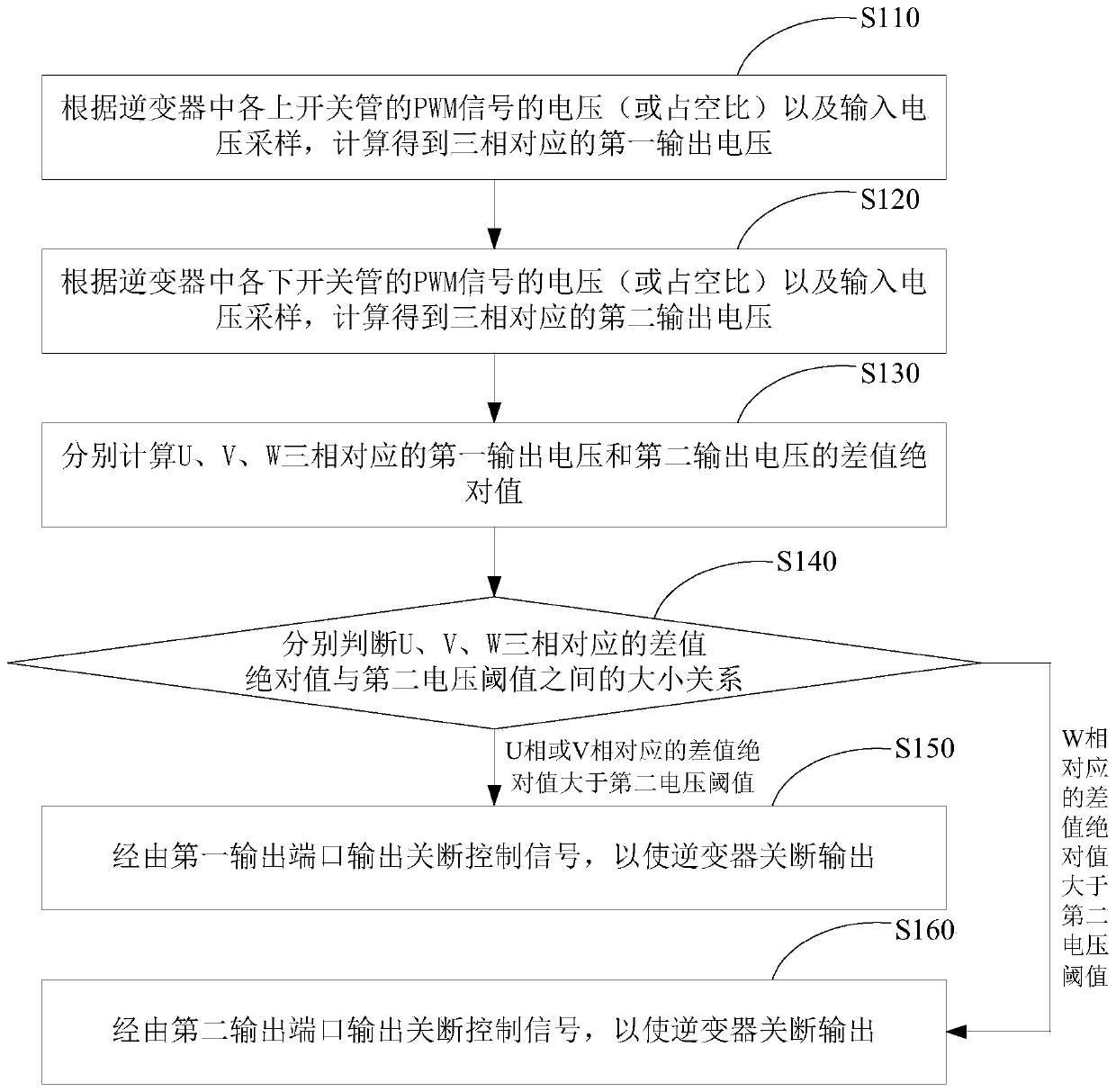

[0063] The current voltage sampling method of the motor driver does not deal with common cause failures, resulting in the inability to perform rationality checks on the sampled voltage signals or inaccurate rationality checks. This application provides a voltage parameter detection device for a motor driver, which performs independent sampling for the same parameter variable, eliminates common cause failure factors, and performs a rationality check on the parameter variable; finally improves the output torque control accuracy of the motor driver .

[0064] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com