Interphase insulation paper, stator core and coil insertion machine

A technology of phase-to-phase insulation and stator core, applied in the direction of laying solid insulation, shape/style/structure of winding insulation, etc., can solve problems such as coil wire leakage, and achieve the effect of less insulation failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

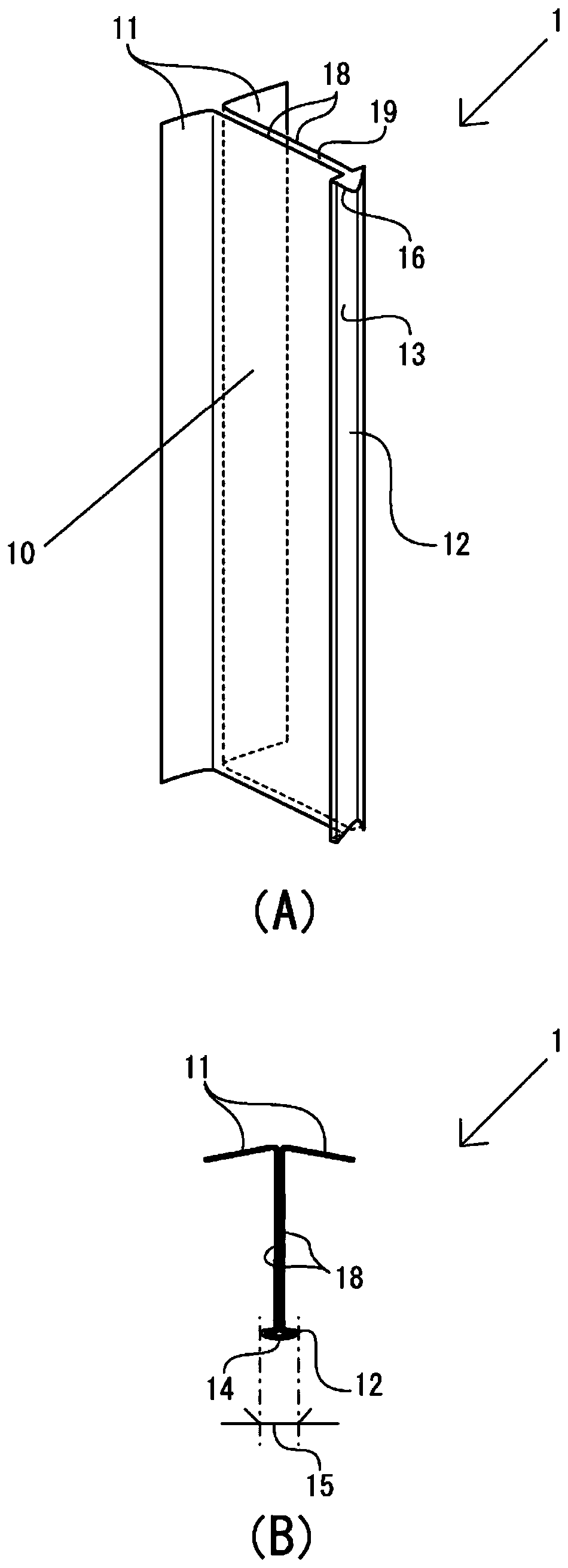

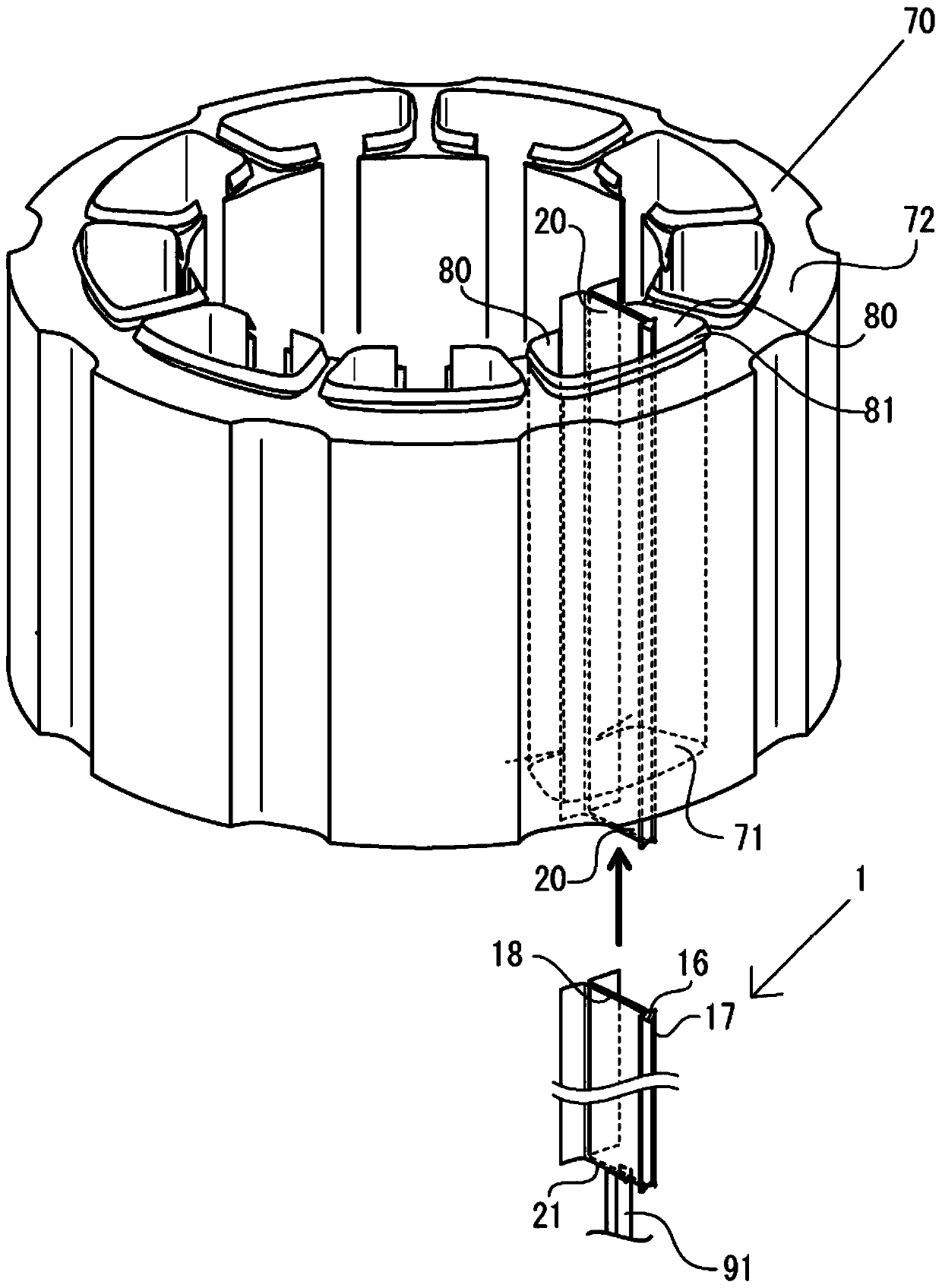

[0060] In the first embodiment, refer to Figure 1 to Figure 8 , the interphase insulating paper 1 , the stator core to which the interphase insulating paper 1 is attached, and the coil insertion machine 200 will be described. The plate body 13 on the outer surface side among the plate bodies is bent. figure 1 (A) is a perspective view showing the interphase insulating paper 1, figure 1 (B) in (B) is a cross-sectional view showing the interphase insulating paper 1 . figure 2 It is a schematic diagram illustrating insertion of the interphase insulating paper 1 into the slot 71 of the stator core 70 .

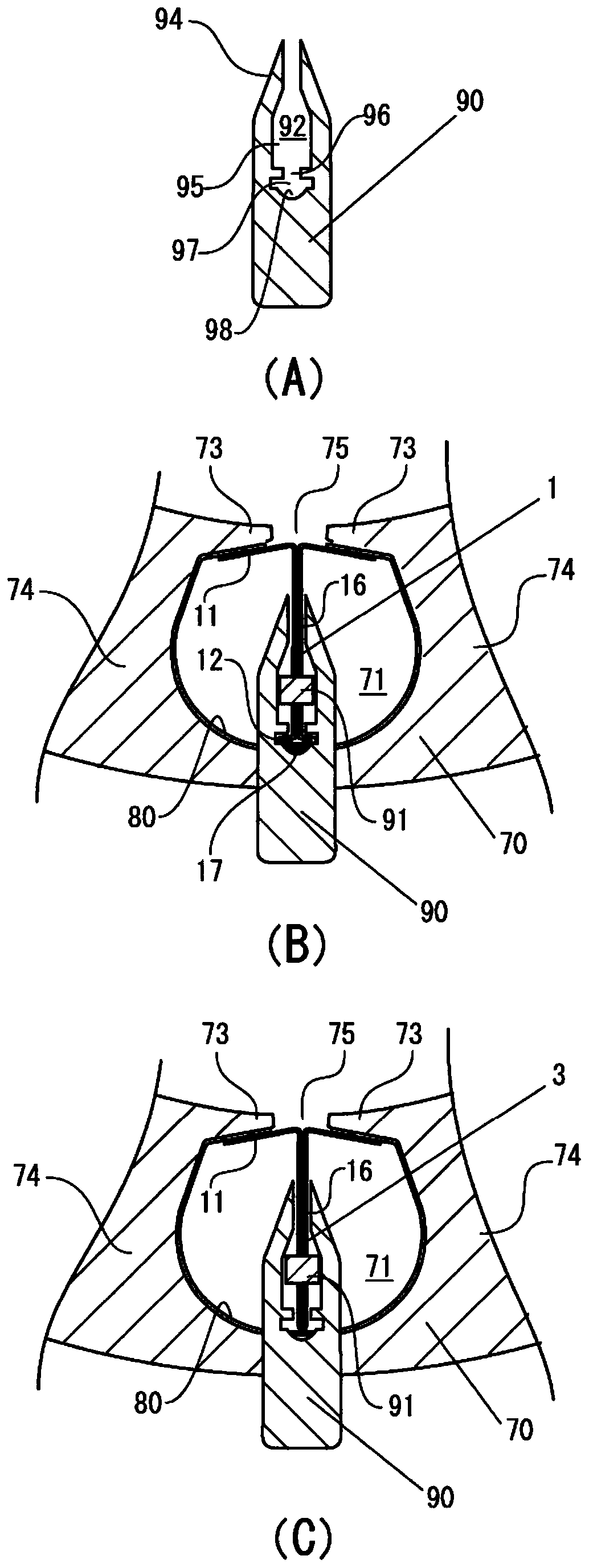

[0061] image 3 (A) in (A) is a sectional view showing the interphase insulating paper guide member 90, image 3 (B) in and image 3 Each figure of (C) is a figure for explaining the position between the slot 71, the interphase insulating paper guide member 90, and the interphase insulating paper 1. image 3 (B) in and image 3 Each figure in (C) is shown from Figure 4 ...

no. 2 example

[0085] In the second embodiment, refer to Figure 9 , the interphase insulating paper 2 in which the convex shape of the radially outer plate body 24 on the front side of the radially outer bent portion is crushed and the thickness of the insertion guide portion 25 is thin will be described briefly. When the interphase insulating paper 2 is bent by the bending die, only the front side becomes the insertion guide part 25 which is heated and compressed in the thickness direction and crushed to form a thin sheet thickness. By making the insertion guide portion 25 thin, when the interphase insulating paper 2 is inserted, the front side portion 26 of the interphase insulating paper is not caught by the first insulating paper, and the insertion is smooth.

[0086] In addition, since only the insertion guide portion 25 is heated and compressed, almost the entire length of the outer-diameter-side bent portion 12 is always in a state of protruding outward, and the first insulating pape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com