Ceramic powder, dielectric paste using same, multilayer ceramic electronic component, and method for production thereof

A ceramic powder and electronic component technology, which is applied in the field of ceramic powder, can solve the problems of poor manufacturing yield, cracks, peeling, etc., and achieve the effects of improving manufacturing yield, reducing cracks or delamination, and improving withstand voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0031] Hereinafter, the ceramic powder and dielectric paste of the present invention are applied, and further, a laminated ceramic electronic component (here, a laminated ceramic capacitor) using them and a method of manufacturing the same will be described in detail.

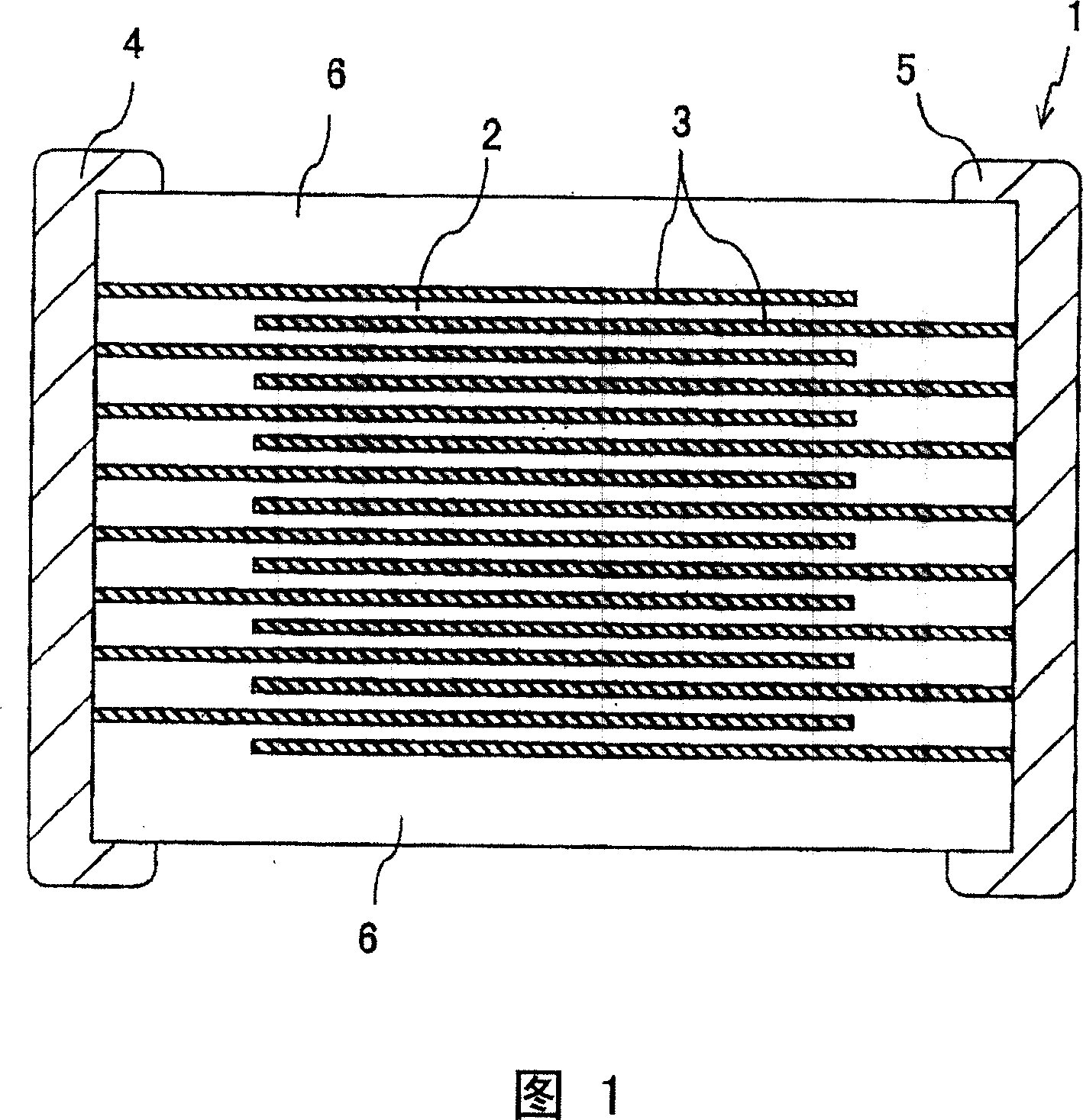

[0032] First, a multilayer ceramic capacitor using the ceramic powder of the present invention will be described. As shown in FIG. 1 , in a multilayer ceramic capacitor 1 , a plurality of dielectric ceramic layers 2 and internal electrode layers 3 are alternately stacked to form a device body. The internal electrode layers 3 are laminated so that the opposite end faces of the device body are exposed alternately, and a pair of external electrodes 4, 5 are formed on both ends of the device body to conduct with these internal electrode layers 3 . In addition, in the device body, the outer dielectric layer 6 is arranged at both ends of the stacking direction of the dielectric ceramic layer 2 and the internal electro...

Embodiment

[0063] Hereinafter, specific examples to which the present invention is applied will be described based on experimental results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com