Brake device of double-bearing reel

A braking device and reel technology, which is applied to fishing reels, fishing, applications, etc., can solve the problems of complicated device assembly and poor insulation, and achieve the effects of easy assembly and alleviation of poor insulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0052] First embodiment (R3526, 3527)

[0053] 〔The composition of the reel〕

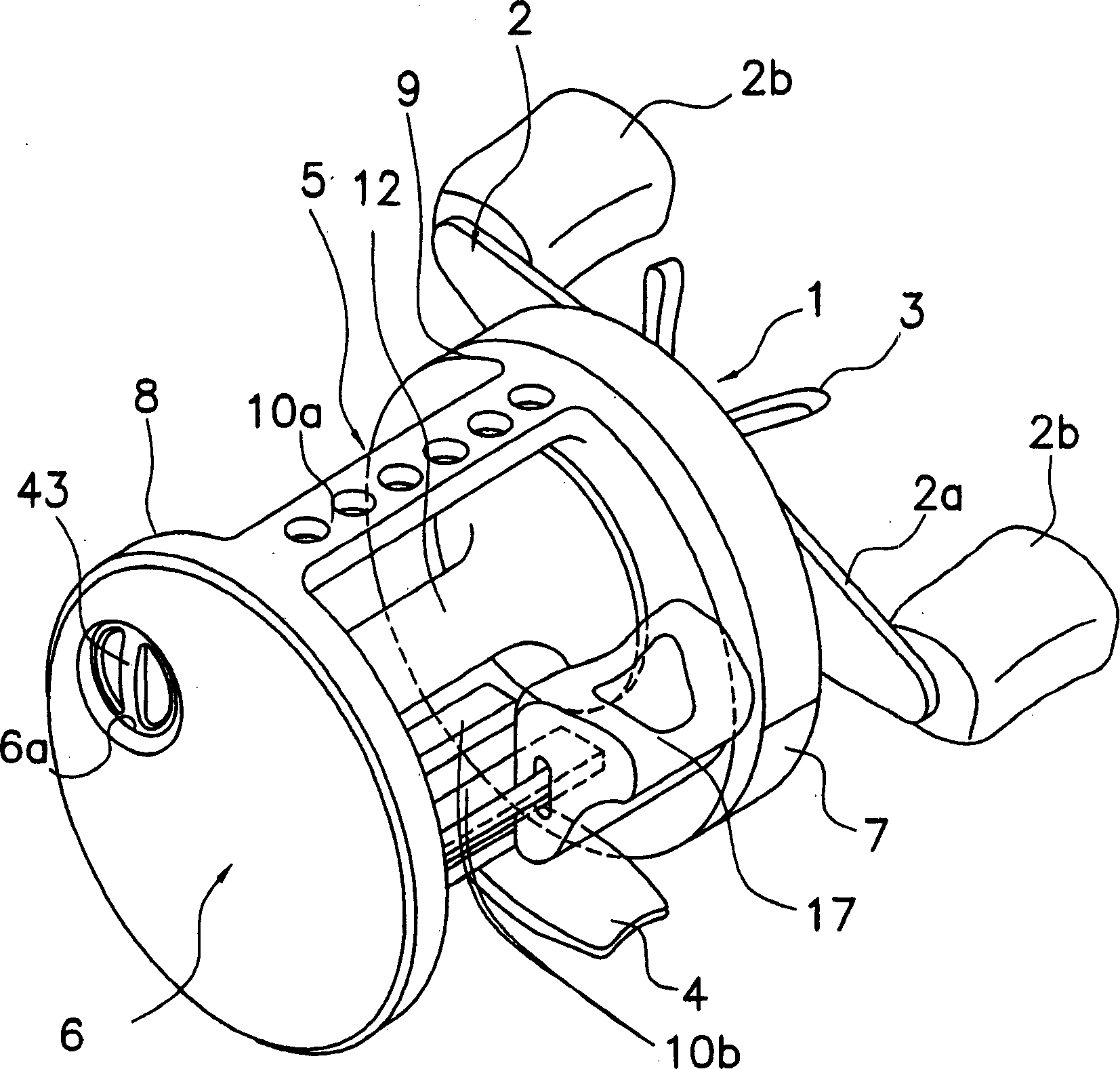

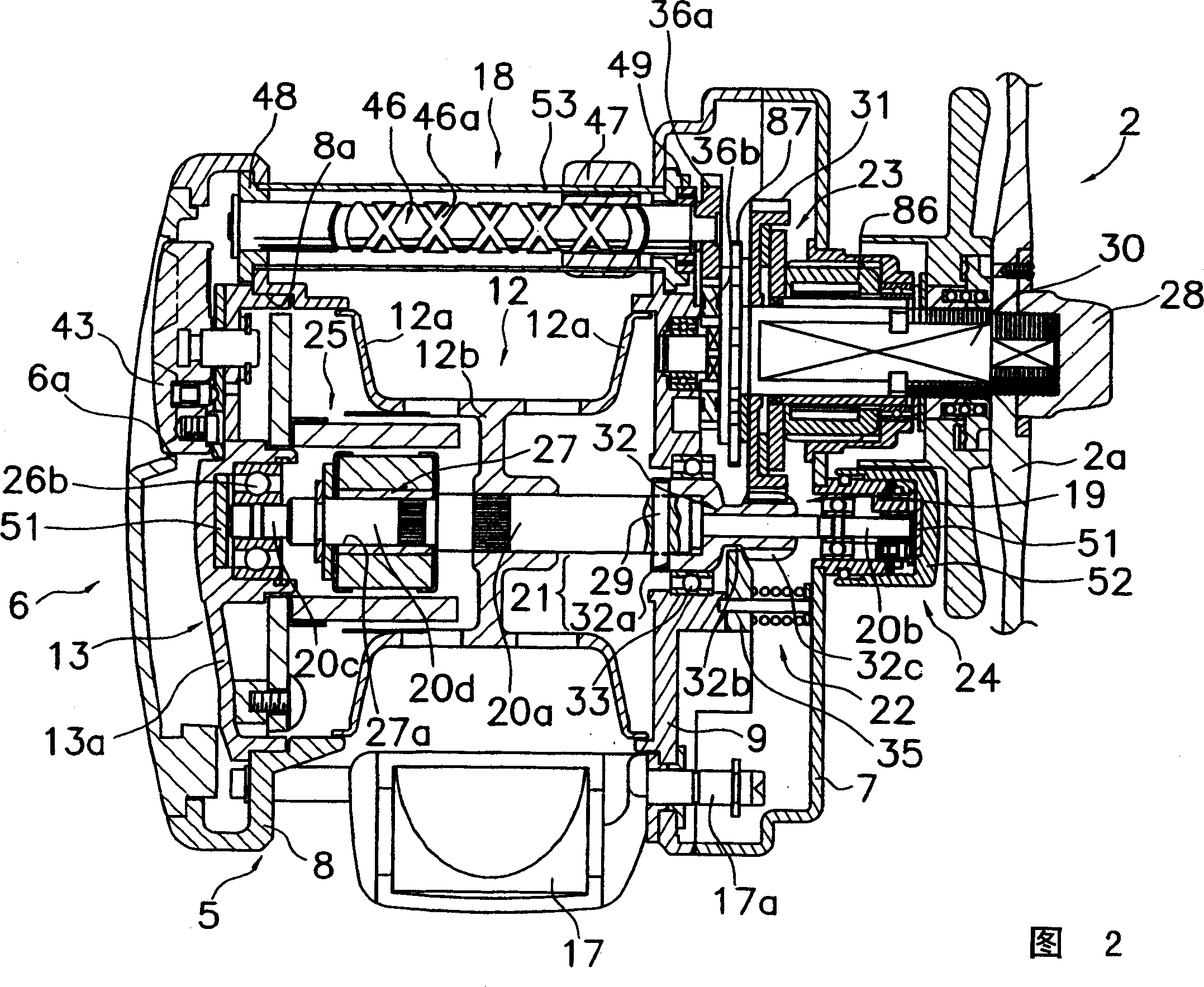

[0054] in figure 1 As shown in Fig. 2, the double-bearing reel obtained by one embodiment of the present invention is a round double-bearing reel for bait casting. The reel has: a reel body 1, a handle for reel rotation arranged on the side of the reel body 1, 2, a star traction for traction adjustment on the side of the reel body 1 arranged on the handle 2器3.

[0055] The handle 2 is a double handle-shaped member having a plate-shaped arm portion 2a and a handle 2b rotatably attached to both ends of the arm portion 2a. As shown in FIG. 2, the arm portion 2a is mounted on the front end of the handle shaft 30 so as not to rotate, and is fastened to the handle shaft 30 by a nut 28.

[0056] The reel main body 1 is a member made of metal such as aluminum alloy or magnesium alloy, and includes a member 5 and a first side cover 6 and a second side cover 7 mounted on both sides of the member 5. The reel 12 f...

no. 2 Embodiment approach

[0120] Second embodiment (R3580)

[0121] In the aforementioned first embodiment, although the insulating film 90 is formed on the entire circuit board 70, the insulating film 190 may be selectively formed. In addition, in the following description, the description of the same or equivalent configuration and operation as the first embodiment is omitted.

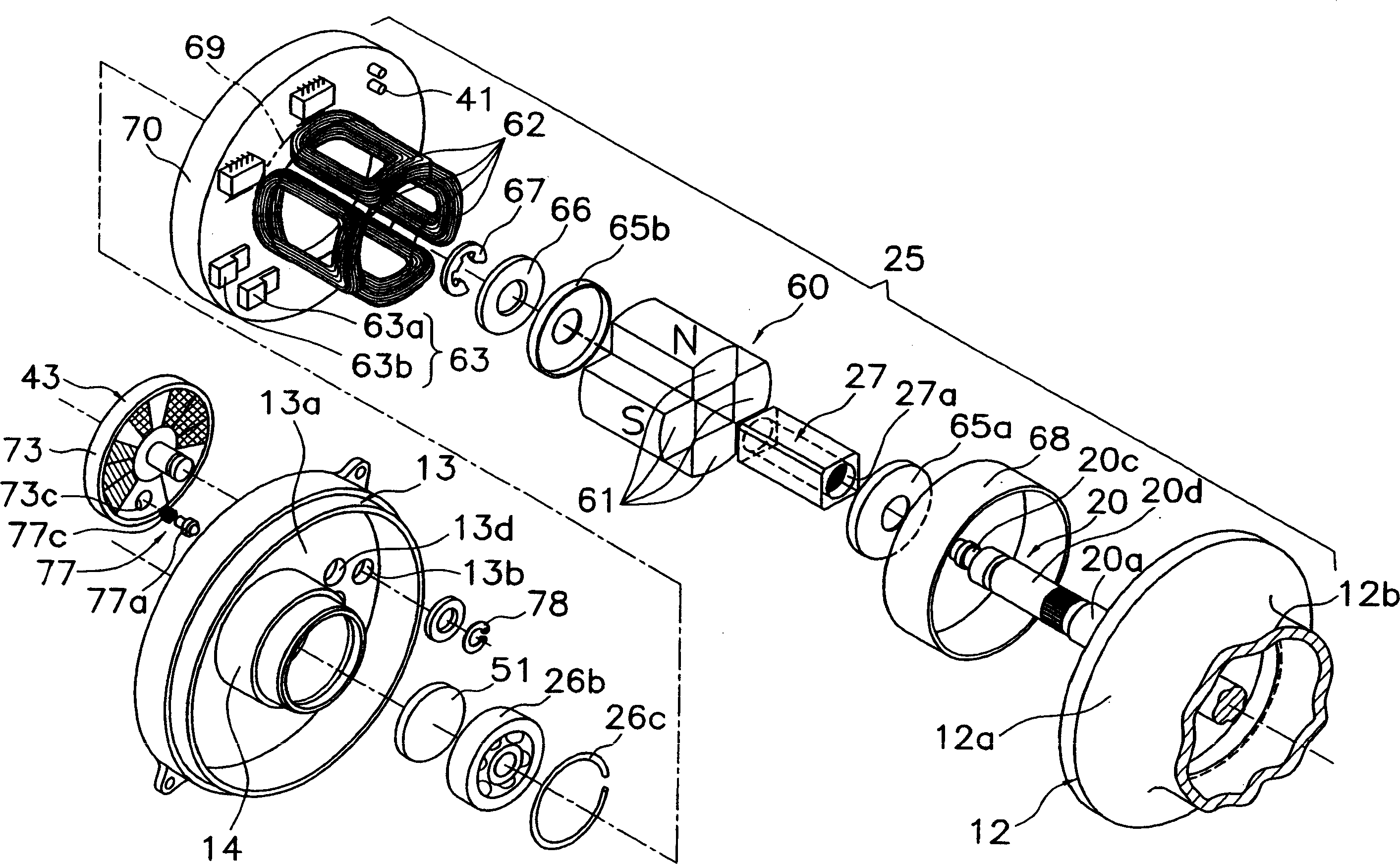

[0122] in Figure 12 ~ Figure 1 In 4, the switching element 63 has two FETs (Field Effect Transistors) 63a and 63b which can be switched at high speed and are connected in parallel. The coil 62 connected in series is connected to the drain terminals of the FETs 63a and 63b. Such as Figure 14B As shown, the switching element 63 is mounted on the back surface of the circuit board 70 (the surface on the opposite side to the surface facing the flange portion 12a).

[0123] The rotation speed sensor 41 uses, for example, a reflective photoelectric sensor 44 having a light projecting portion 44a and a light receiving portion 44b, and ...

no. 3 Embodiment approach

[0132] [Third Embodiment] (R3572)

[0133] In the third embodiment, a case where the molded insulating film 290 is formed by a hot melt molding method will be described. In addition, in the following description, descriptions of configurations and operations that are the same as or equivalent to those of the first and second embodiments are also omitted.

[0134] in Figure 16 As shown in FIG. 17, in the third embodiment, the switching element 63 has, for example, two FETs (Field Effect Transistors) 63a and 63b that can be controlled at high speed and connected in parallel. The coil 62 connected in series is connected to the drain terminals of the FETs 63a and 63b. Such as Figure 17B As shown, the switching element 63 is mounted on the back surface of the circuit board 70 (the surface on the opposite side to the surface facing the flange portion 12a).

[0135]The circuit board 70 is a ring-shaped board having a washer shape with a circular center opening, and is arranged substant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com