Automatic pipe bending machine for spiral tube

A technology of coiled pipe and pipe bending machine, applied in the field of mechanical processing, can solve the problems of poor consistency of spiral spacing of coiled pipe, high labor intensity of operators, low work efficiency, etc. Efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

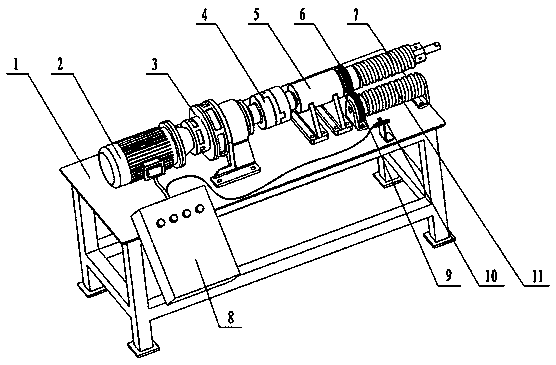

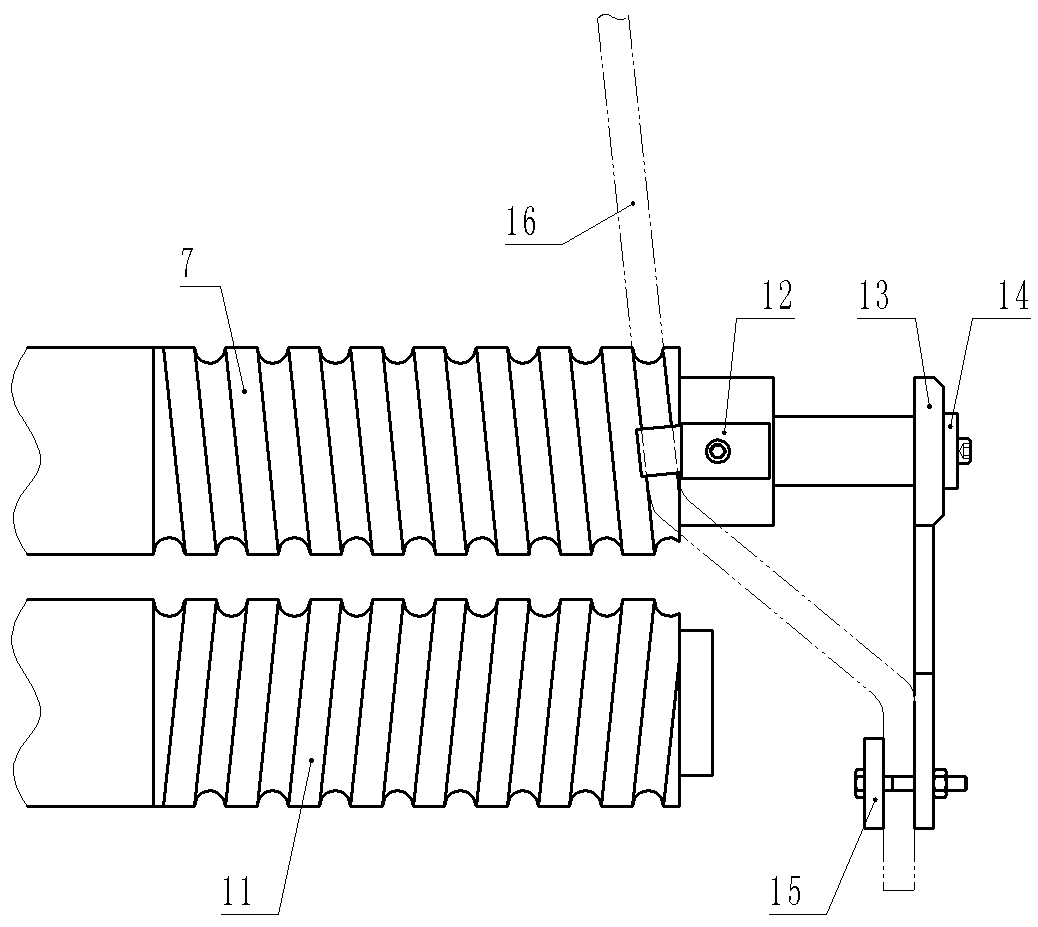

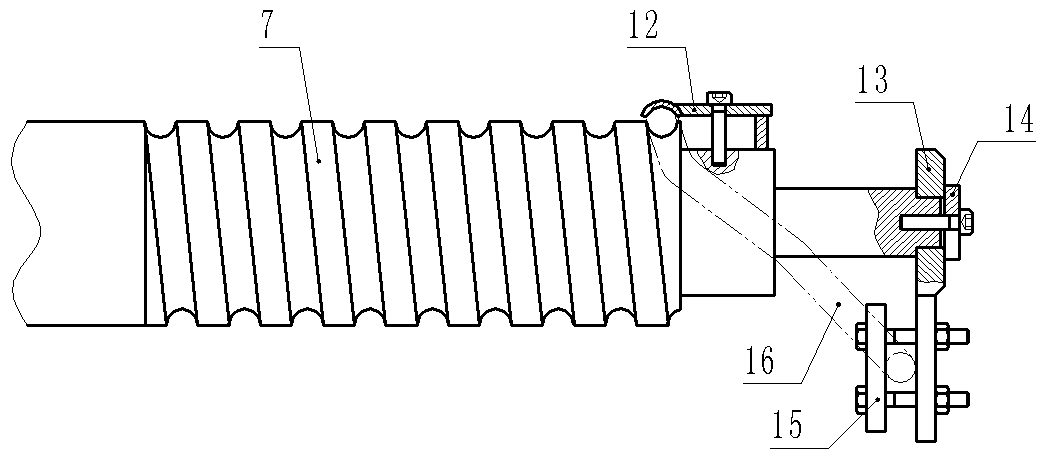

[0024] Such as figure 1 , figure 2 A coiled pipe automatic pipe bending machine shown includes an active spiral pipe bending die 7 with a pipe bending spiral groove. One end of the active spiral pipe bending die 7 is installed on the frame 1 through a bearing and a bearing seat 5, and by decelerating Machine 3 is connected with motor 2, reducer 3 and active spiral pipe bending die 7 are connected by coupling 4, and the other end of active spiral pipe bending die 7 is equipped with a pipe clamping device. One side of the active spiral pipe bending die 7 is equipped with a driven spiral pipe bending die 11 parallel to it, the two ends of the driven spiral pipe bending die 11 are installed on the frame 1 through the support, 11 has guide spiral grooves arranged symmetrically with the bend pipe spiral groove, the cross section of the bend pipe spiral groove and the guide spiral groove is semicircular, the bend pipe spiral groove of the active spiral pipe bending die 7 is a right...

Embodiment 2

[0028] The difference between this embodiment and Embodiment 1 is that the rotational speed of the active spiral pipe bending die 7 when bending the coiled pipe is 15 rpm. All the other features are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com