Compartment type roller hearth furnace heat forming equipment

A technology of thermoforming and floor furnace, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of large amount of blanks scrapped in maintenance costs, scrapped blanks, slow SPM cycle, etc., and achieve input costs and maintenance costs Low cost, simple structure, and the effect of reducing scrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

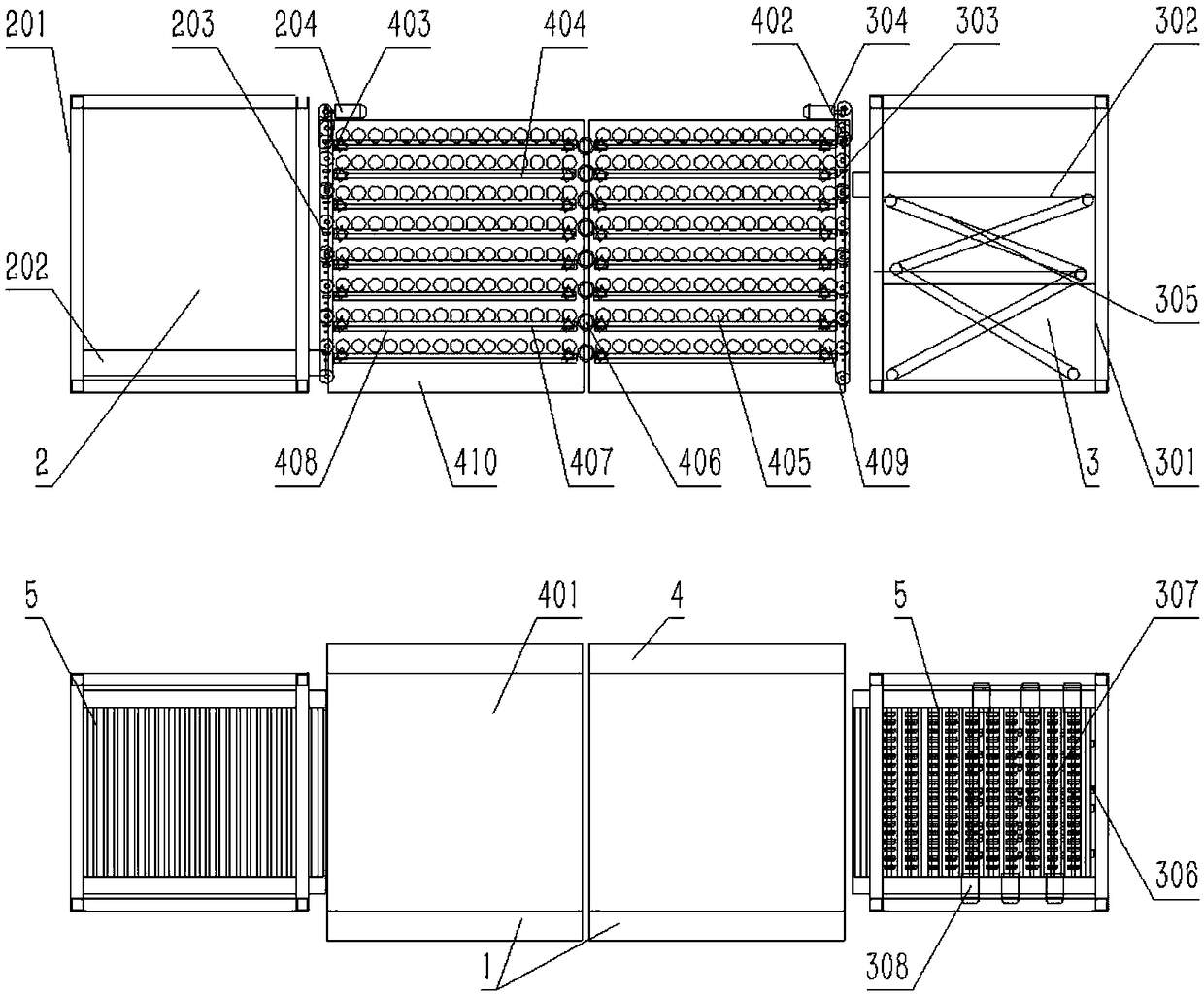

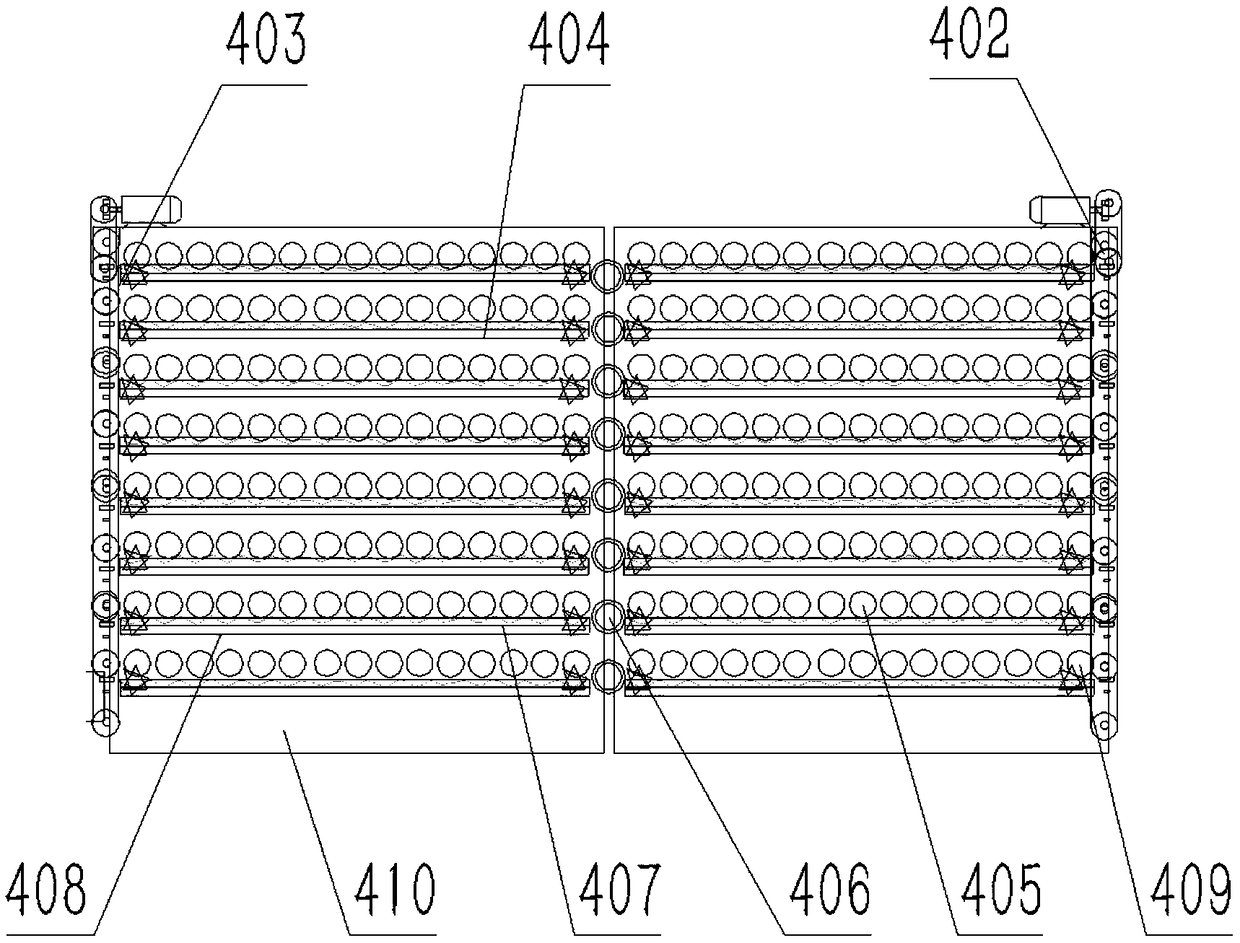

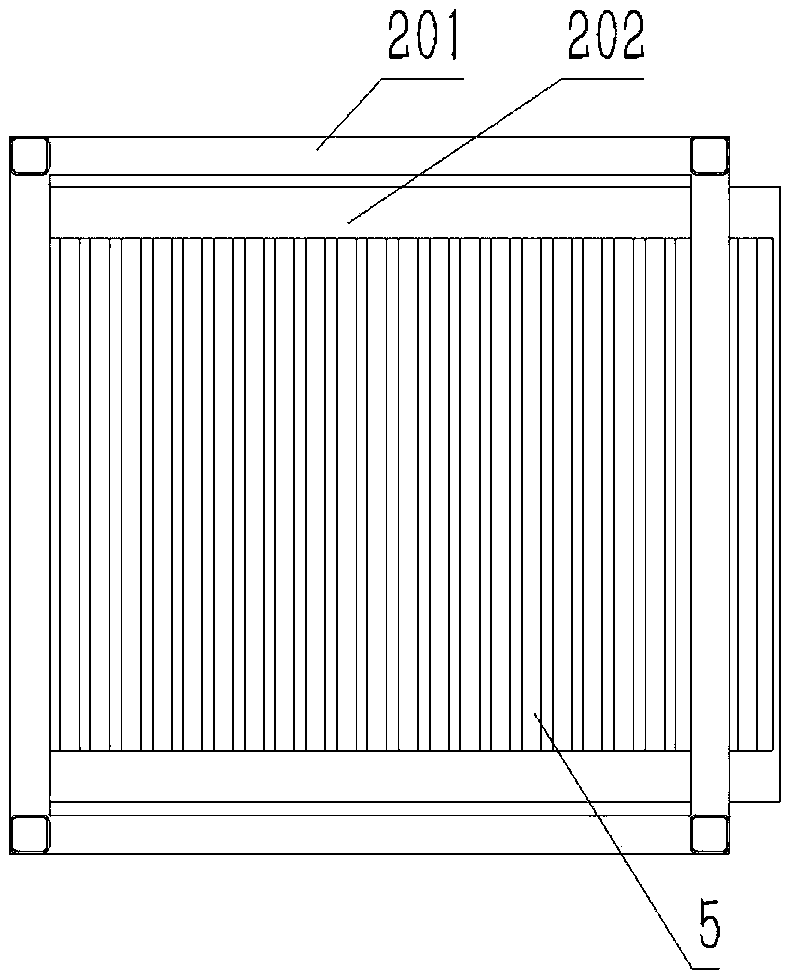

[0022] Please see attached figure 1 to attach Figure 6 As shown, a chamber type rolling furnace thermoforming equipment includes a main furnace 1, an input lifting device 2, and an output lifting device 3; the main furnace 1 includes a pair of box furnaces 4, and a pair of the box Type furnace 4 is arranged at intervals; described box type furnace 4 comprises box type housing 401, maintenance and opening furnace door cylinder 402, production opening furnace door cylinder 403 and several heating layers 404; Several described heating layers 404 are along the vertical direction Evenly arranged in the box-type housing 401; each heating layer 404 includes a moving roller 405, a moving roller servo motor 406, a heating couple 407, a hot air duct 408, a distance sensor 409 and an oxide skin pocket 410; The maintenance opening furnace door cylinder 402 is arr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap