Wear-resistant precise lettering press-riveting machine working device and heat treatment process thereof

A working device and riveting machine technology, applied in heat treatment furnaces, heat treatment equipment, stamping, etc., can solve the problems of reducing production efficiency and production quality, increasing the working intensity of staff, wear and corrosion, etc., and achieve simple product structure, Ease of operation and reduced scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

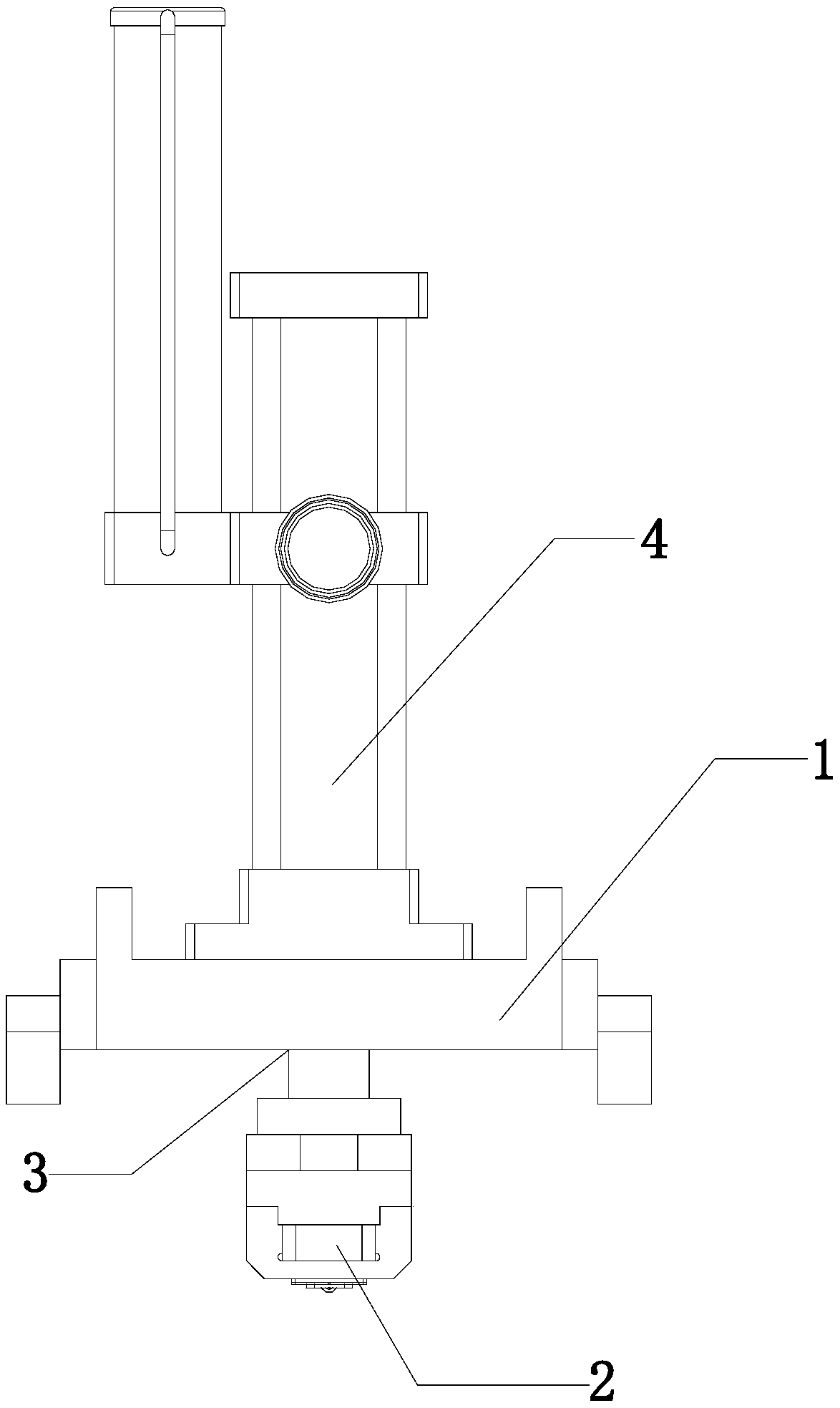

[0046] This embodiment provides a working device for a wear-resistant precision lettering riveting machine. The middle part of the working bracket 1 is provided with a prefix mounting hole 3 from top to bottom, and the working prefix 2 is clamped in the prefix mounting hole 3. The working The top of the word head 2 extends vertically upwards with a booster cylinder 4. The working support 1 and the working head 2 are made of high-precision metal, and their weight percentages are: Mo: 0.63%, Al: 2.26%, Ru: 1.31% , Zn: 1.56%, K: 3.33%, Mn: 4.17%, Sr: 2.28%, Ba: 1.23%, Sr: 3.34%, rare earth: 35%, the rest is Fe and trace impurities;

[0047] Among the rare earths, the following components are contained by weight percentage: Nd: 9.65%, Eu: 2.33%, Sm: 1.35%, Pd: 4.67%, Cr: 2.34%, and the balance is Ag;

[0048] The casting process of the working device of the wear-resistant precision lettering riveting press includes:

[0049] (1) Core making: Use resin sand to make sand cores acco...

Embodiment 2

[0064] This embodiment provides a working device for a wear-resistant precision lettering riveting machine. The middle part of the working bracket 1 is provided with a prefix mounting hole 3 from top to bottom, and the working prefix 2 is clamped in the prefix mounting hole 3. The working The top of the word head 2 extends vertically upwards with a booster cylinder 4, the working support 1 and the working head 2 are made of high-precision metal, and their weight percentages are: Mo: 0.86%, Al: 2.98%, Ru: 2.25% , Zn: 1.98%, K: 3.56%, Mn: 4.78%, Sr: 2.87%, Ba: 1.45%, Sr: 4.78%, rare earth: 38%, the rest is Fe and trace impurities;

[0065] Among the rare earths, the following components are included by weight percentage: Nd: 10.23%, Eu: 3.45%, Sm: 2.23%, Pd: 5.46%, Cr: 5.66%, and the balance is Ag;

[0066] The casting process of the working device of the wear-resistant precision lettering riveting press includes:

[0067] (1) Core making: Use resin sand to make sand cores acco...

Embodiment 3

[0082] This embodiment provides a working device for a wear-resistant precision lettering riveting machine, including a working bracket 1 and a working prefix 2 that is compatible with the working bracket. The middle part of the working bracket 1 is provided with a prefix installation hole 3 from top to bottom. , the working word head 2 is stuck in the word head mounting hole 3, and the top of the working word head 2 extends vertically upwards with a pressurized cylinder 4. The working bracket 1 and the working word head 2 are made of high-precision metal materials, and their weight percentages are all For: Mo: 0.75%, Al: 2.75%, Ru: 1.66%, Zn: 1.75%, K: 3.45%, Mn: 4.32%, Sr: 2.54%, Ba: 1.33%, Sr: 4.52%, rare earth: 36 %, the rest is Fe and trace impurities;

[0083] The rare earth contains the following components by weight percentage: Nd: 9.78%, Eu: 3.12%, Sm: 1.78%, Pd: 5.23%, Cr: 4.22%, and the balance is Ag;

[0084] The casting process of the working device of the wear-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com