Cobweb type anti-blocking fluidization ash conveying method and system used for dust remover

A dust collector and fluidization technology, which is applied in the field of blast furnace ash conveying engineering, can solve the problems of inability to realize ash conveying, high operating costs, high bulk density, etc., and achieve the effects of saving gas consumption for ash conveying, smooth ash conveying, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

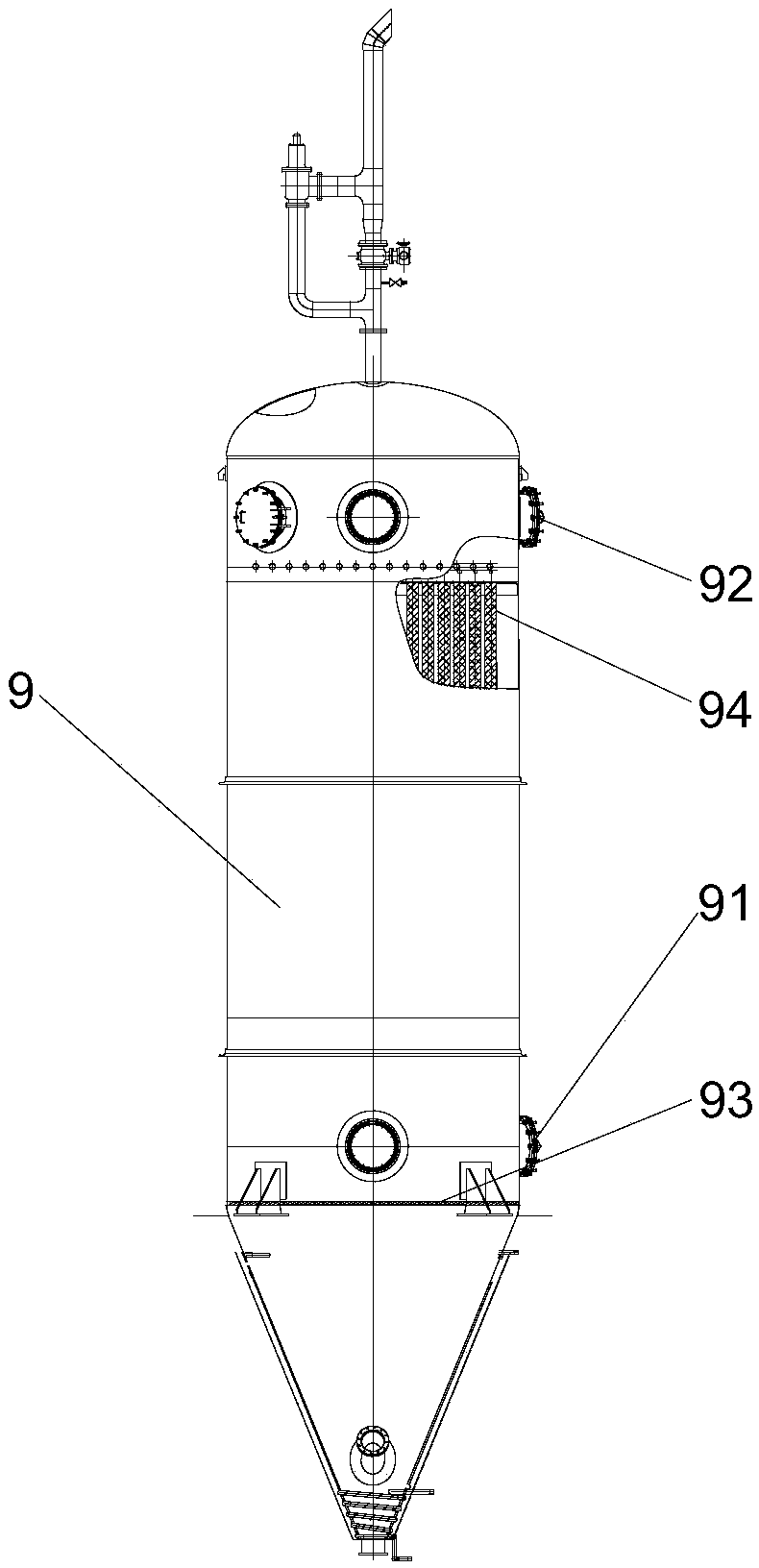

[0064] Such as Figure 4 to Figure 16 As shown, the present invention provides a cobweb type anti-blocking fluidized ash conveying system for a dust collector, which includes: a dust collector 1, the lower end of which is provided with an ash hopper 11, and the side wall of the ash hopper 11 is pierced to discharge ash Conduit 12, the outlet of the ash discharge conduit 12 is connected to the ash conveying air supply pipe 13; the fluidizer 2 is fixed at the lower end of the ash hopper 11, and the fluidizer 2 is located at the end of the ash discharge conduit 12 Below the inlet, the lower end inlet of the fluidizer 2 is connected to the fluidization air supply pipe 26, and the upper end of the fluidizer 2 is provided with a fluidization plate 23, and the fluidizer 2 is connected to the fluidization plate 23 through the fluidization plate 23. The ash hopper 11 is connected.

[0065] Specifically, the dust collector 1 is generally in the shape of a cylinder, and has a filter ele...

Embodiment approach 2

[0084] The present invention also provides a cobweb-type anti-clogging fluidized ash conveying method for dust collectors (that is, a spider-web-type anti-clogging fluidized ash conveying method), wherein the spider-web-type anti-clogging fluidized ash conveyance method for dust collector The method adopts the above-mentioned cobweb type anti-clogging fluidized ash conveying system for the dust collector, and the structure, working principle and effect of the spider web anti-clogging fluidized ash conveying system for the dust collector are the same as those in Embodiment 1 , not repeating them here, the cobweb type anti-clogging fluidized ash conveying method for the dust collector includes the following steps:

[0085] Step a, open the fluidization gas supply valve 27 on the fluidization gas supply pipe 26, the fluidization gas enters the fluidizer 2 and enters the ash hopper 11 through the fluidization plate 23, so that the ash in the ash hopper 11 is in a fluidized suspensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com