Antimony sulfide purification device

A technology of antimony sulfide and small crucible, which is applied in antimony sulfide, inorganic chemistry, antimony compounds, etc. It can solve the problems of not particularly remarkable effect and inaccurate purification precision, so as to increase the purification rate, suppress pollution, and reduce oxidation absorption. gas effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

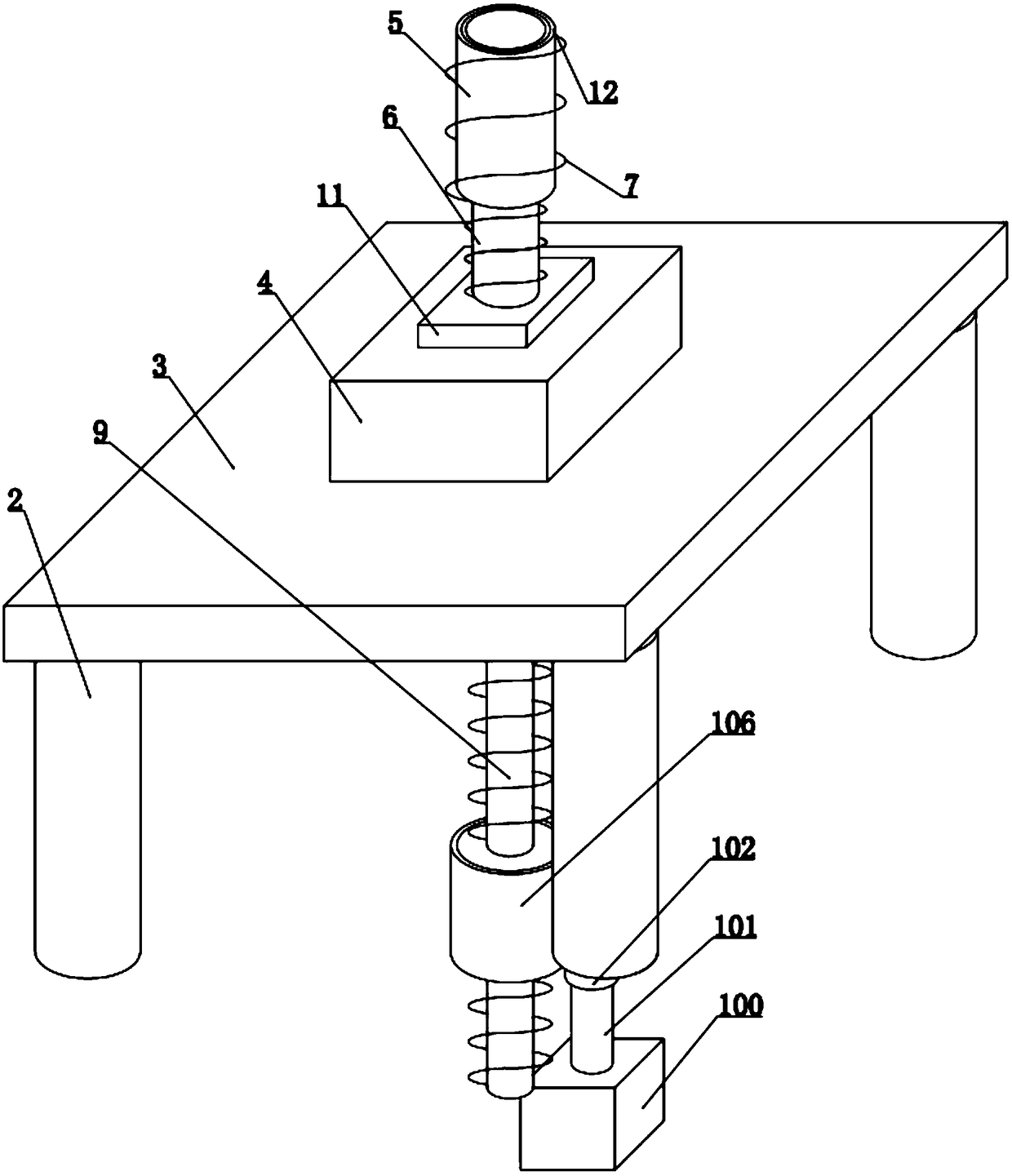

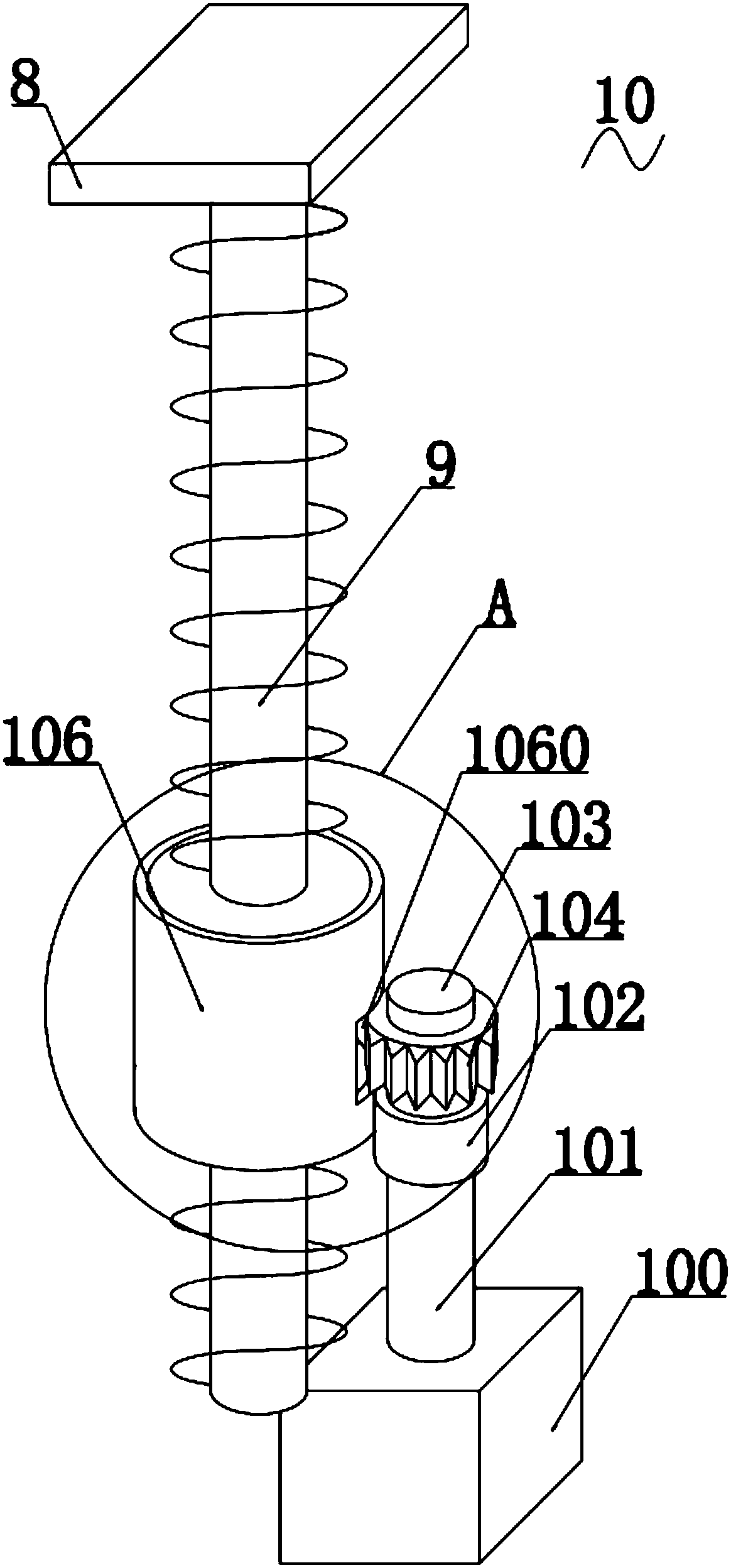

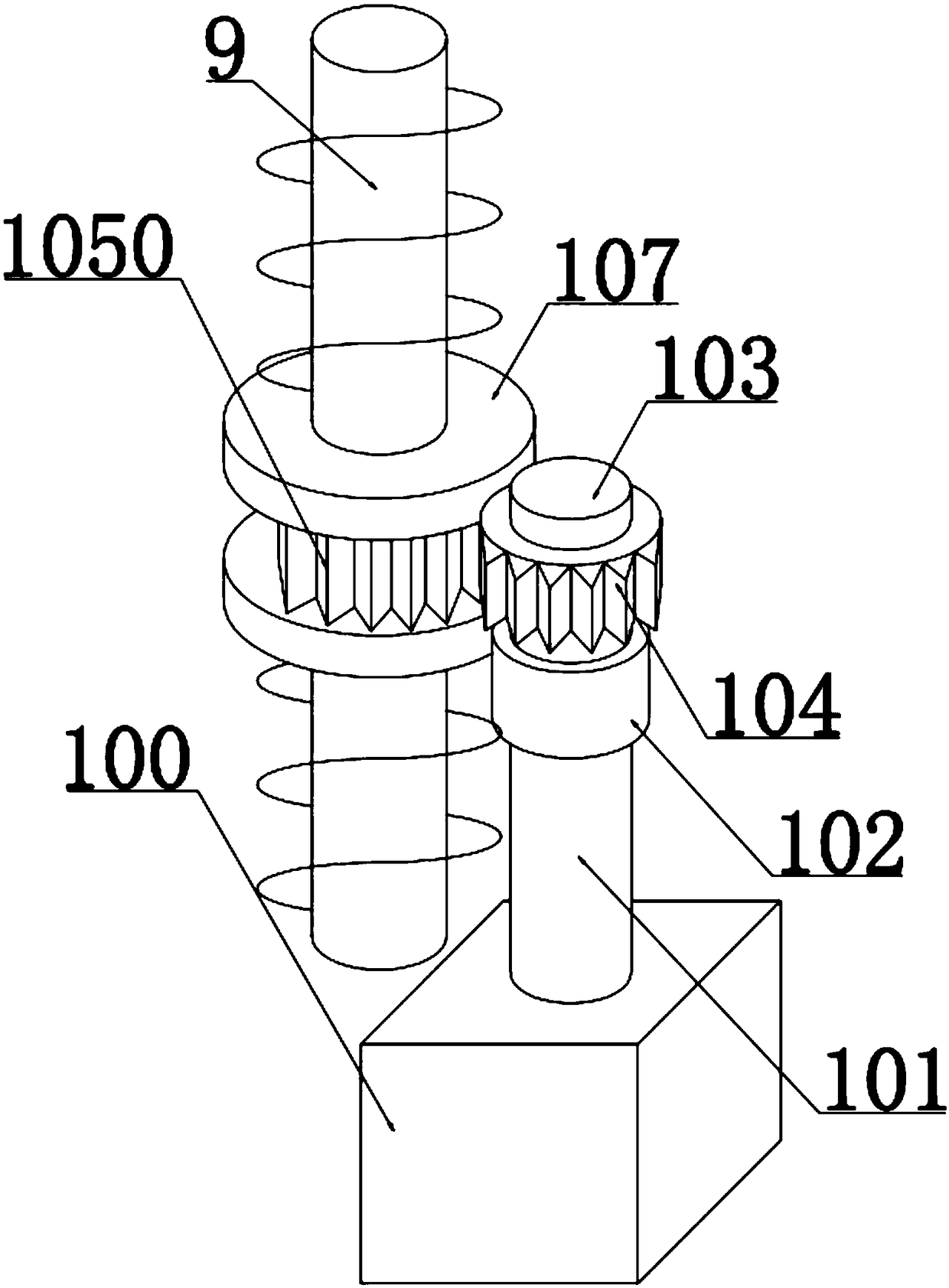

[0024] The present invention provides an antimony sulfide purification device, which includes a vacuum furnace chamber 1, a support 2, a fixed seat 3, a condenser 4, a large crucible 5, a small crucible 6, a coil 7, a crystallization table 8, a lead screw 9, a power assembly 10 and controller, the support 2 is fixedly arranged at the bottom of the cavity of the vacuum furnace chamber 1, the fixed seat 3 is fixedly arranged at the top of the support 2, and the condenser 4 is fixedly arranged at the bottom of the fixed seat 3 At the top, the small crucible 6 passes through the condenser 4 and the fixing seat 3 respectively, the large crucible 5 is fixedly arranged on the top of the small crucible 6, and the large crucible 5 and the small crucible 6 are connected to each other. connected, the bottom of the small crucible 6 is provided with an opening, the crystallization table 8 is arranged below the small crucible 6, the coil 7 is arranged around the periphery of the large crucib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com