Tunnel ventilation vertical shaft wellbore construction device and method

A technology of tunnel ventilation and construction device, which is applied to shaft equipment, shaft lining, well sinking, etc., can solve the problems of long construction period, slow construction speed, and difficulty in treatment of shotcrete cracking, and achieves good effect, improved construction speed, The effect of avoiding the problem of sprayed concrete cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

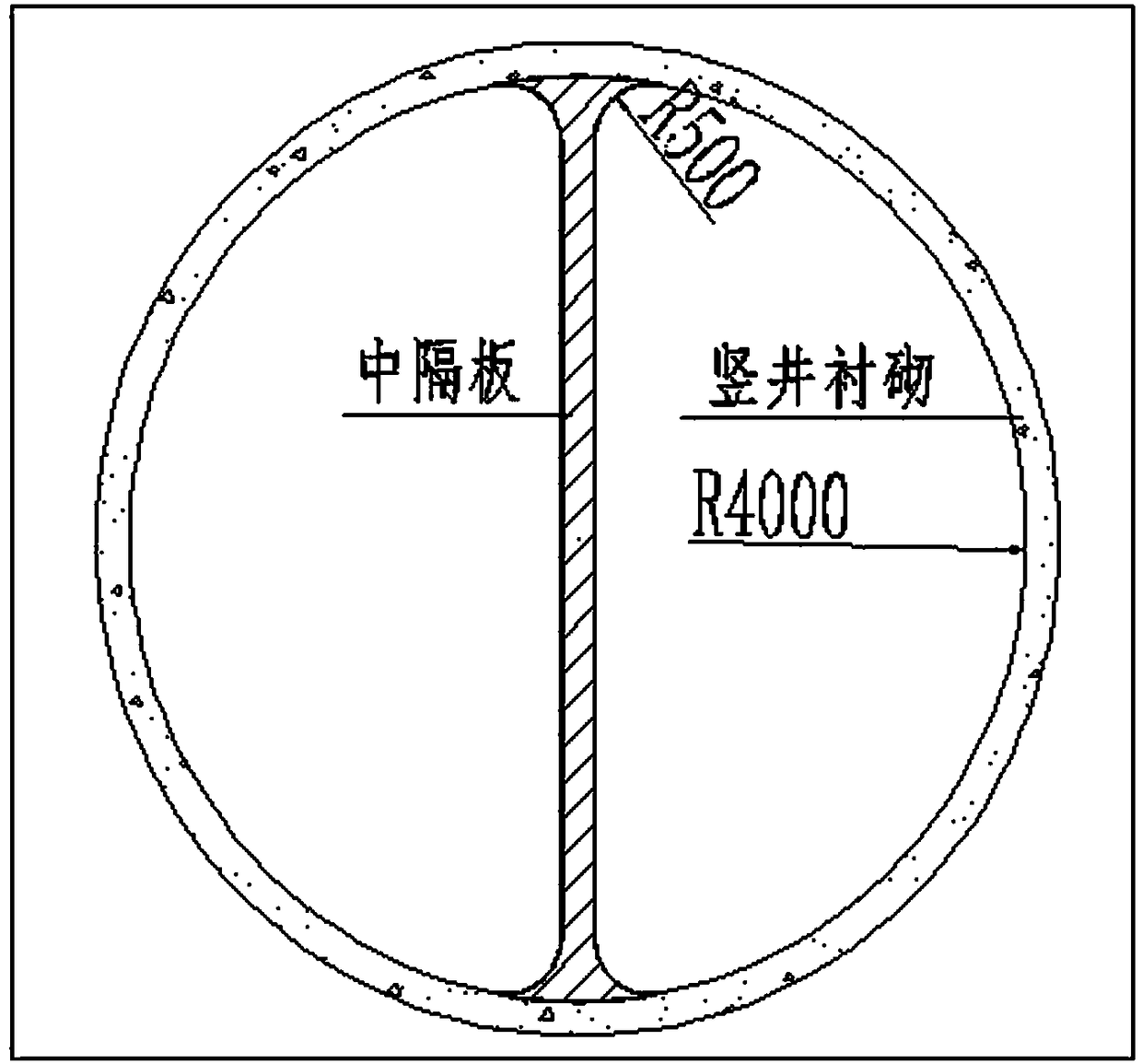

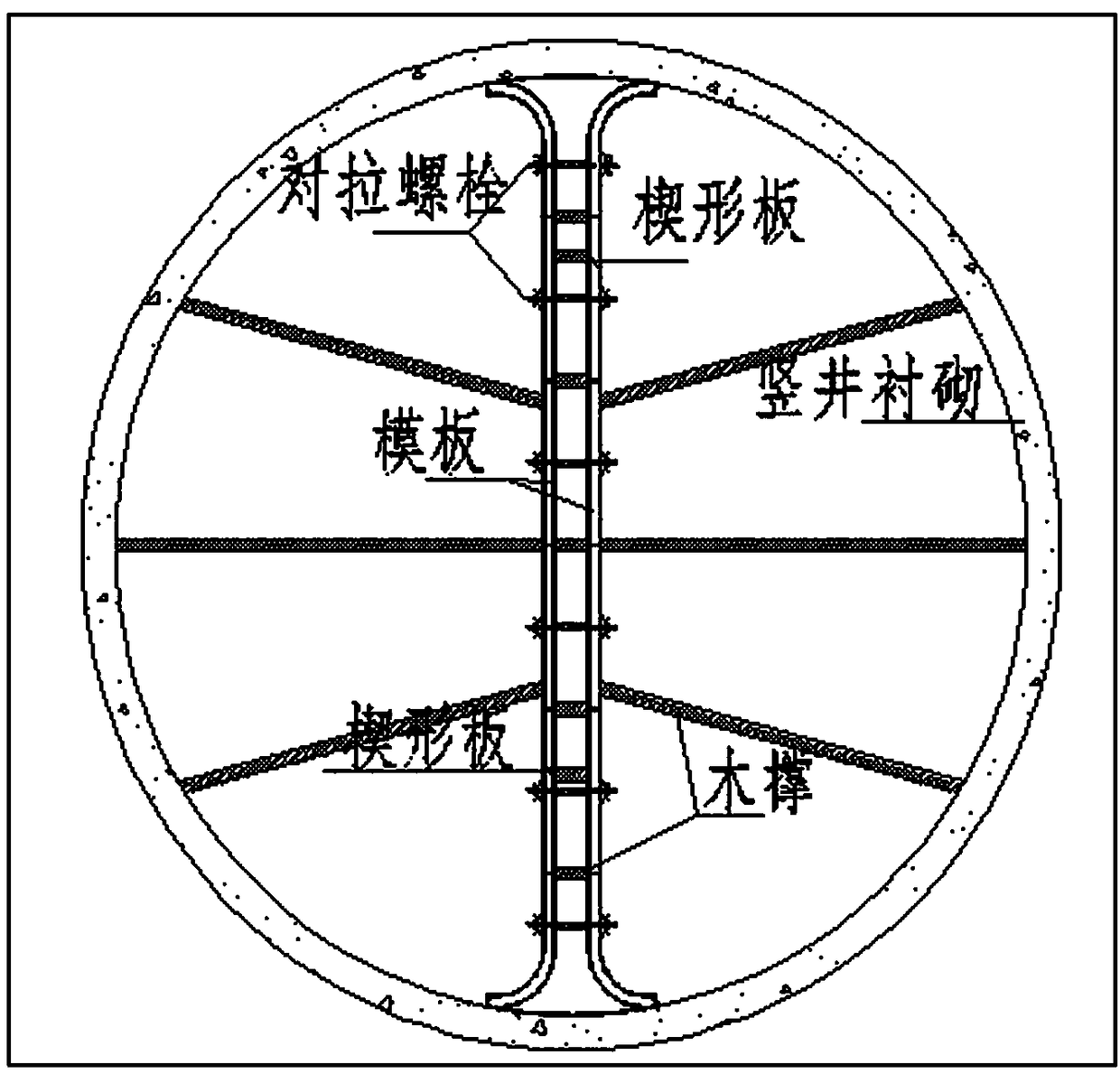

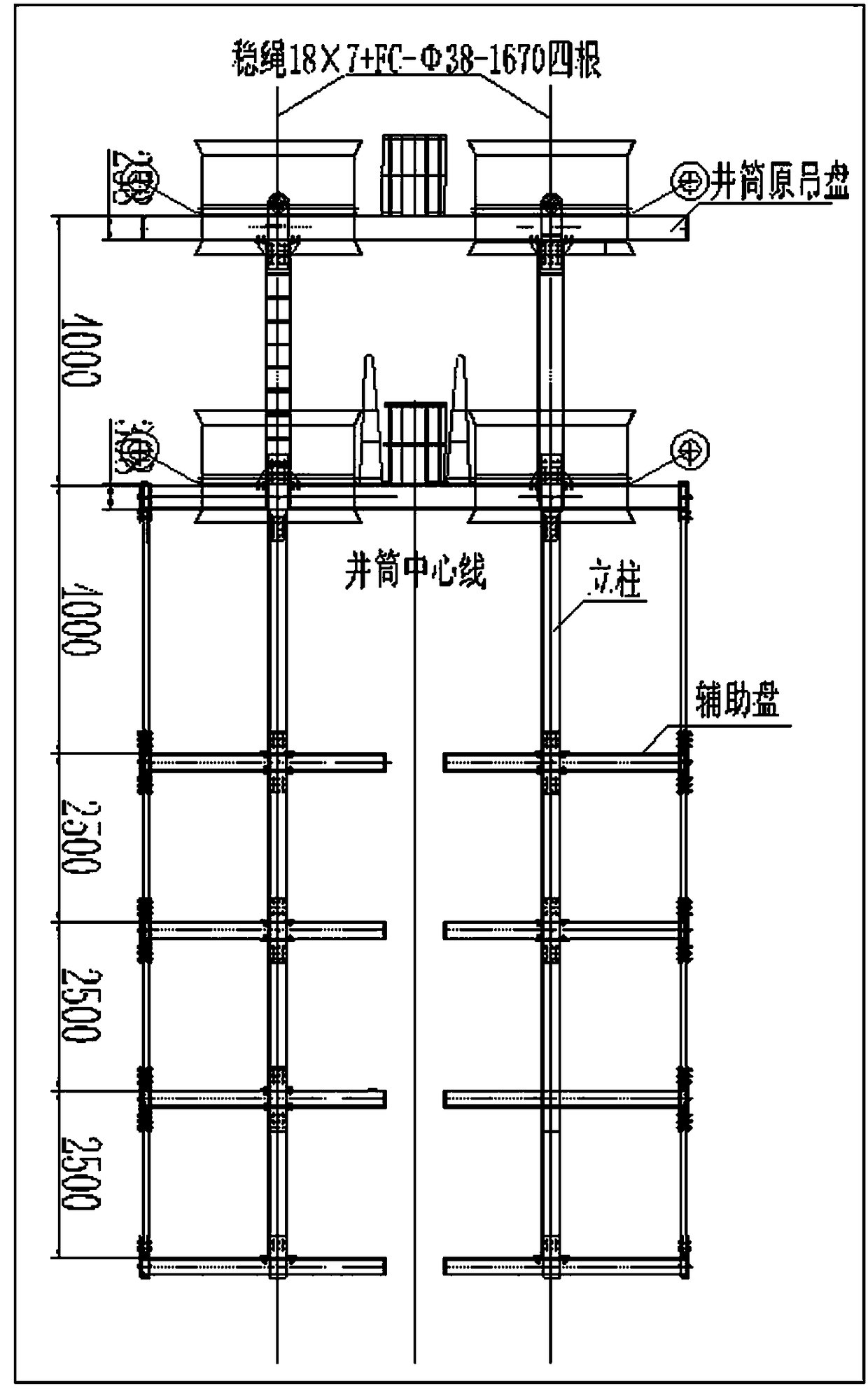

[0018] Such as figure 2 , 3 As shown, the tunnel ventilation shaft shaft construction device is composed of a shaft construction device and a partition construction device, wherein the shaft shaft construction device is an umbrella drill frame rock drill, the partition construction device includes a construction suspension plate and a formwork, and the shaft partition The construction adopts the prefabricated formwork, and the construction hanging plate of the middle partition is a six-layer hanging plate, of which the first and second hanging plates are double-layer hanging plates with an integral structure, and the third, fourth, fifth, and sixth layer hanging plates are all It is a split-type symmetrical crescent-shaped temporary hanging pan. The first and second hanging pans are equipped with fully enclosed guardrails and skirting boards. The third, fourth, fifth, and sixth hanging pans The upper part adjacent to the partition is provided with hinges to facilitate the as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com