Fan blade structure of axial fan

A technology of axial flow fan and fan blade, which is applied in the field of fan blade structure, and can solve the problems of axial flow fan such as low working efficiency and low efficiency, high air volume, high air pressure, low noise, and weakened blade strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

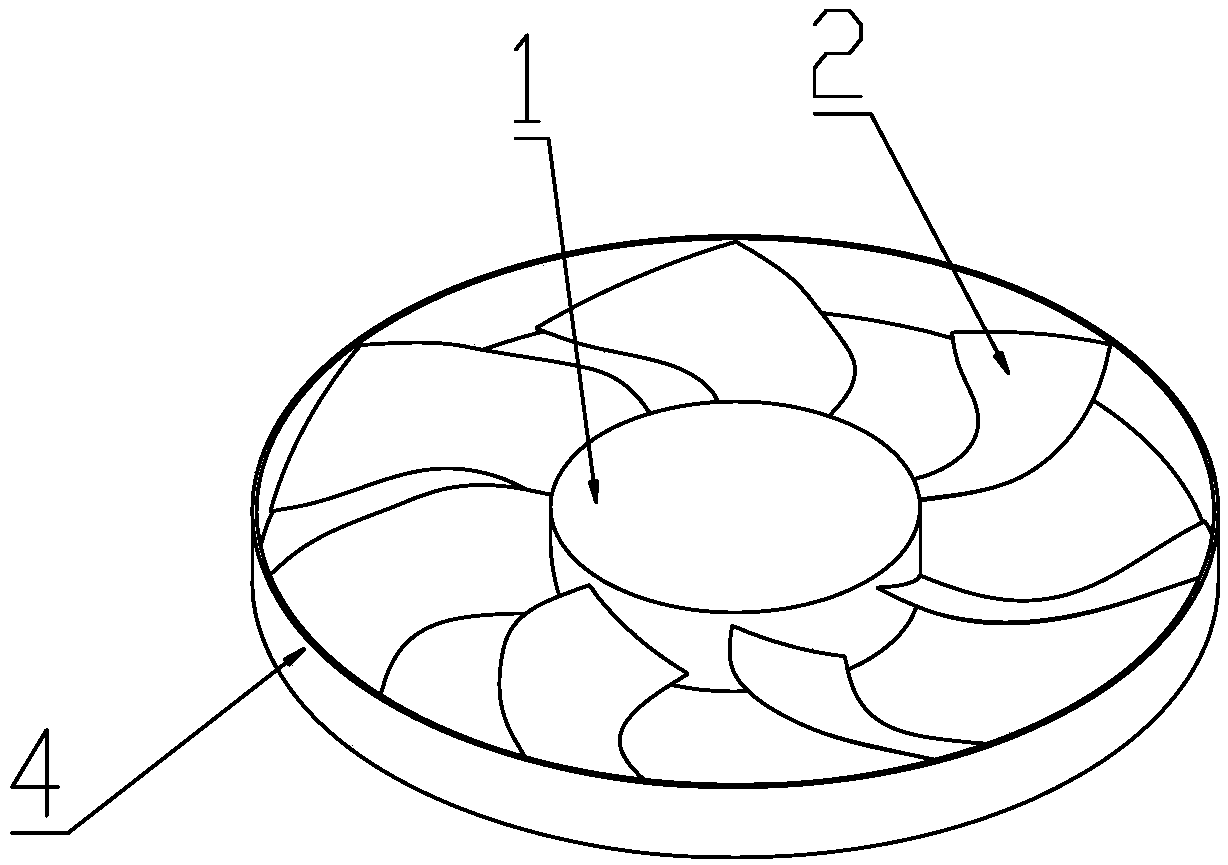

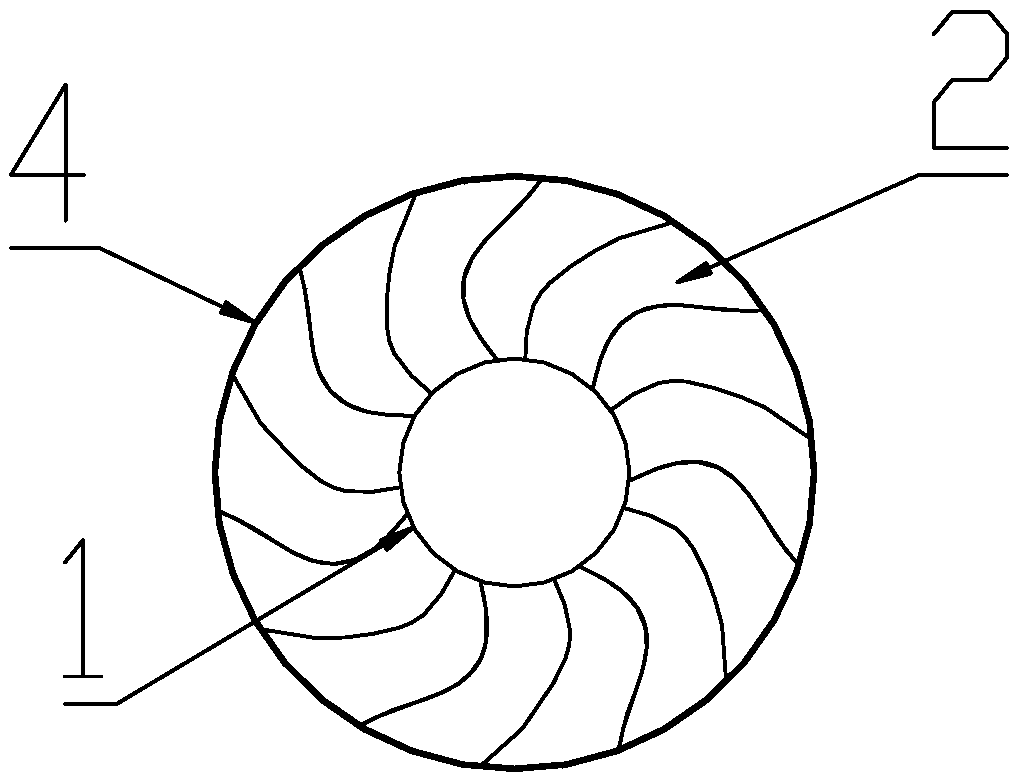

[0022] Referring to the accompanying drawings, specific embodiments of the present invention will be described in detail.

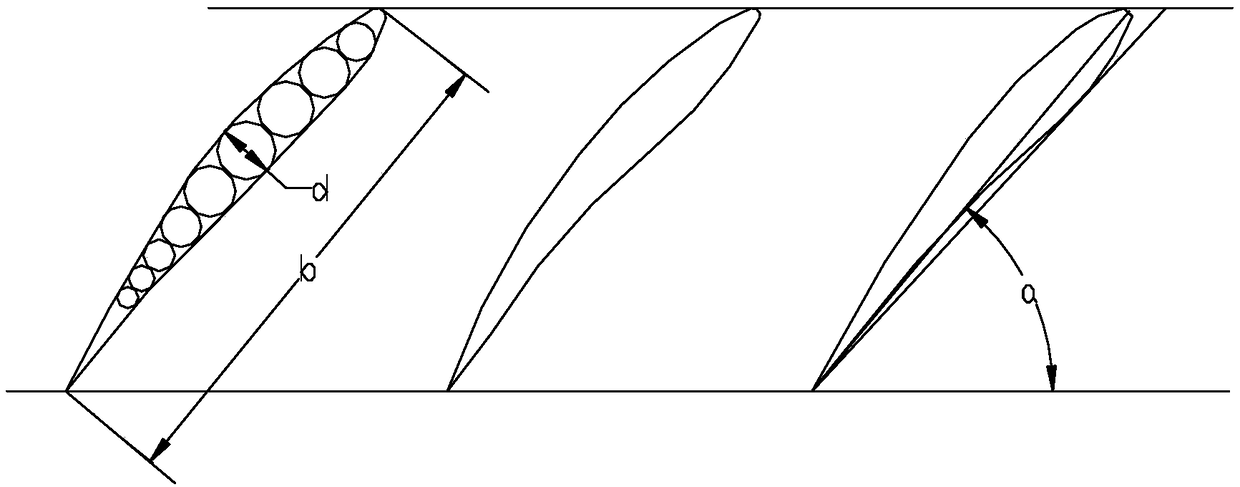

[0023] see Figure 1 to Figure 4 , a fan blade 2 structure of an axial flow fan, including a hub 1 and a plurality of fan blades 2 of the same shape distributed around the hub 1, the diameter of the fan hub 1 is 169.84mm, preferably, the outer peripheral wall of the hub 1 is uniform An odd number of fan blades 2 with the same shape are fixedly connected. This structure prevents the overall symmetrical structure of the fan blades 2 and can avoid vibration caused by the symmetrical structure during motion. In this embodiment, seven fan blades 2 with the same shape are evenly fixed to the outer peripheral wall of the hub 1 . The plurality of fan blades 2 are fan blades 2 with LS airfoil characteristics, and each fan blade 2 includes five characteristic sections. The section is 132.32mm, the third characteristic section is 166.75mm, the fourth characteristi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com