Skeleton layer for marine flexible pipe, and composite flexible pipe

A skeleton layer, flexible pipe technology, applied in the direction of pipes/pipe joints/fittings, hoses, pipes, etc., can solve the problems of loss, flexible pipe oil and gas transportation safety threats, humming and other problems, achieve smooth flow, avoid flow caused by Vibration phenomenon, the effect of solving flow-induced vibration and humming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

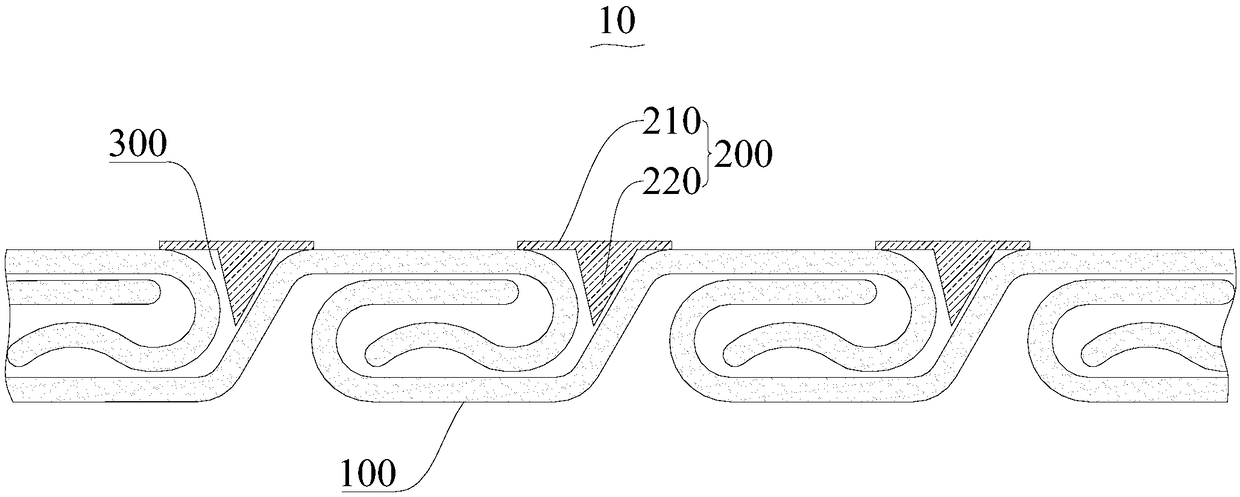

[0053] refer to figure 1 and figure 1 , the present invention provides a skeleton layer 10 of a flexible marine pipe, which is arranged on the innermost layer of the flexible pipe for marine use, and has the functions of supporting, resisting external pressure other than the skeleton layer 10 and preventing the composite flexible pipe 1 from being under strong pressure. The effect of being crushed.

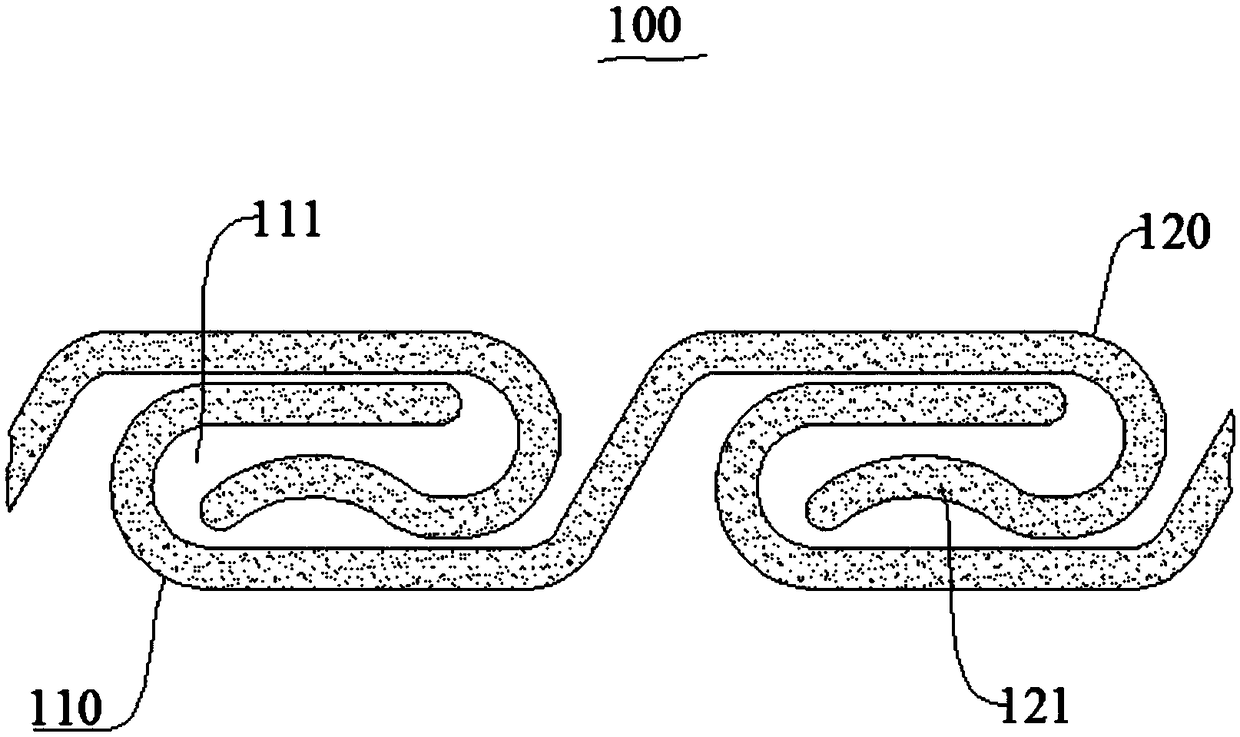

[0054] The skeleton layer 10 includes a first shaped belt 100 and a second shaped belt 200 .

[0055] The first special-shaped belt 100 is spirally wound to form a tubular skeleton layer body, and a spiral groove 300 is formed on the inner surface of the skeleton layer body;

[0056] The first special-shaped belt 100 and the second special-shaped belt 200 are interlaced and spirally wound to close the opening of the spiral groove.

[0057] The material of the first special-shaped belt 100 is a metal frame such as stainless steel, nickel alloy steel or molybdenum alloy steel, so...

Embodiment 2

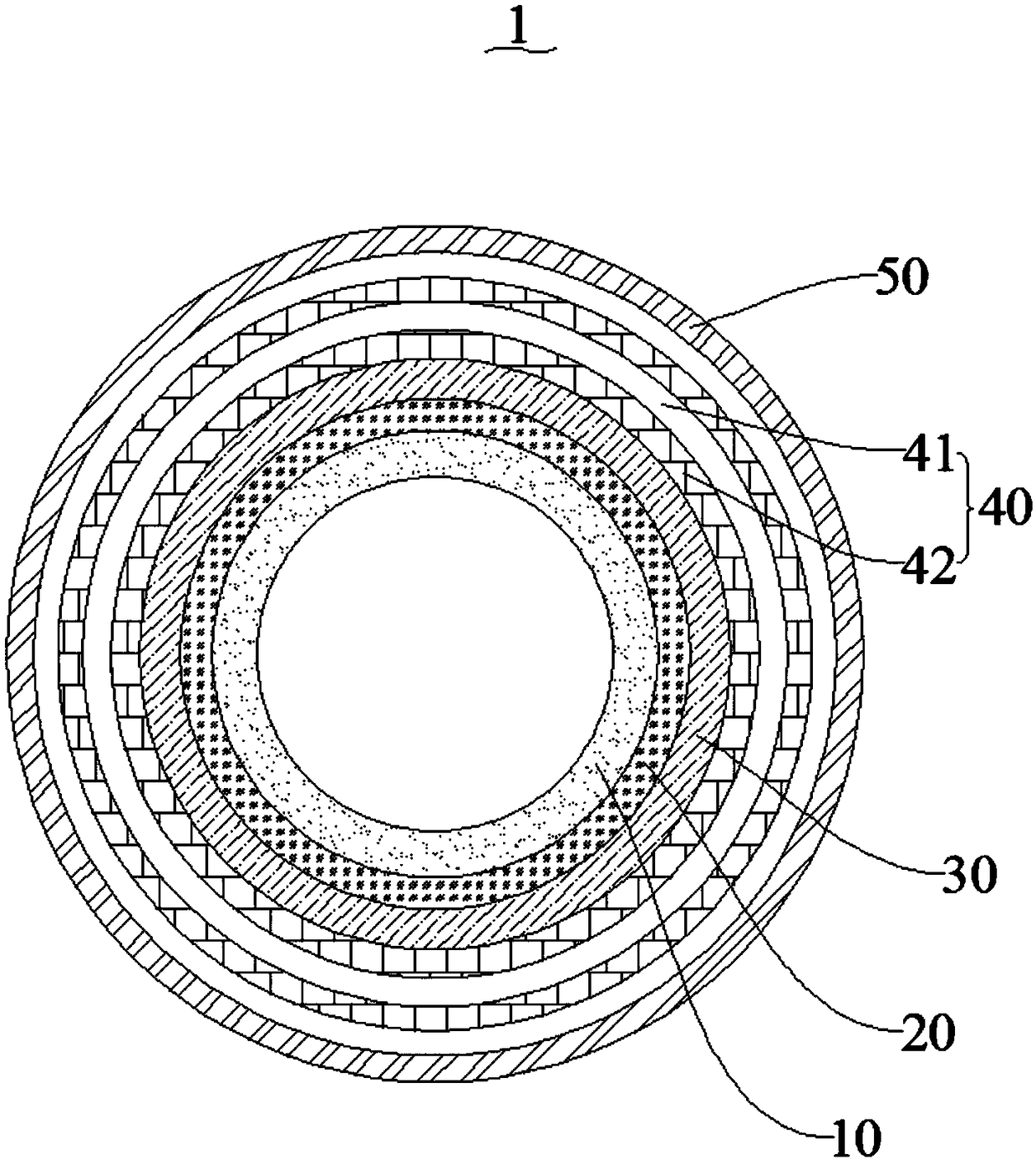

[0070] The present invention also provides a composite flexible pipe 1, which can be used in deep sea or ultra-deep sea. The pipe wall of the composite flexible pipe 1 includes a skeleton layer 10 arranged on the innermost side.

[0071] Preferably, as image 3 As shown, the composite flexible pipe 1 of this embodiment can also include an inner liner 20 wrapped on the outer surface of the skeleton layer 10, a compressive armor layer 30 wrapped on the outer surface of the inner liner 20, and a compressive armor layer wrapped on the outer surface of the inner liner 20. The protective sheath layer 50 on the outer surface of 30 may of course also include at least one combined layer of tensile armor layer 41 and wear-resistant layer 42 disposed between the compressive armor layer 30 and the protective sheath layer.

[0072] Such as figure 1 and figure 2 As shown, the skeleton layer 10 includes a first shaped belt 100 and a second shaped belt 200 . The first special-shaped belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com