Telescopic pipeline inner wall robot

A technology of telescopic pipes and robots, applied to special pipes, pipe components, mechanical equipment, etc., can solve problems such as stuck, rollover, complex structure, etc., and achieve the effect of avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

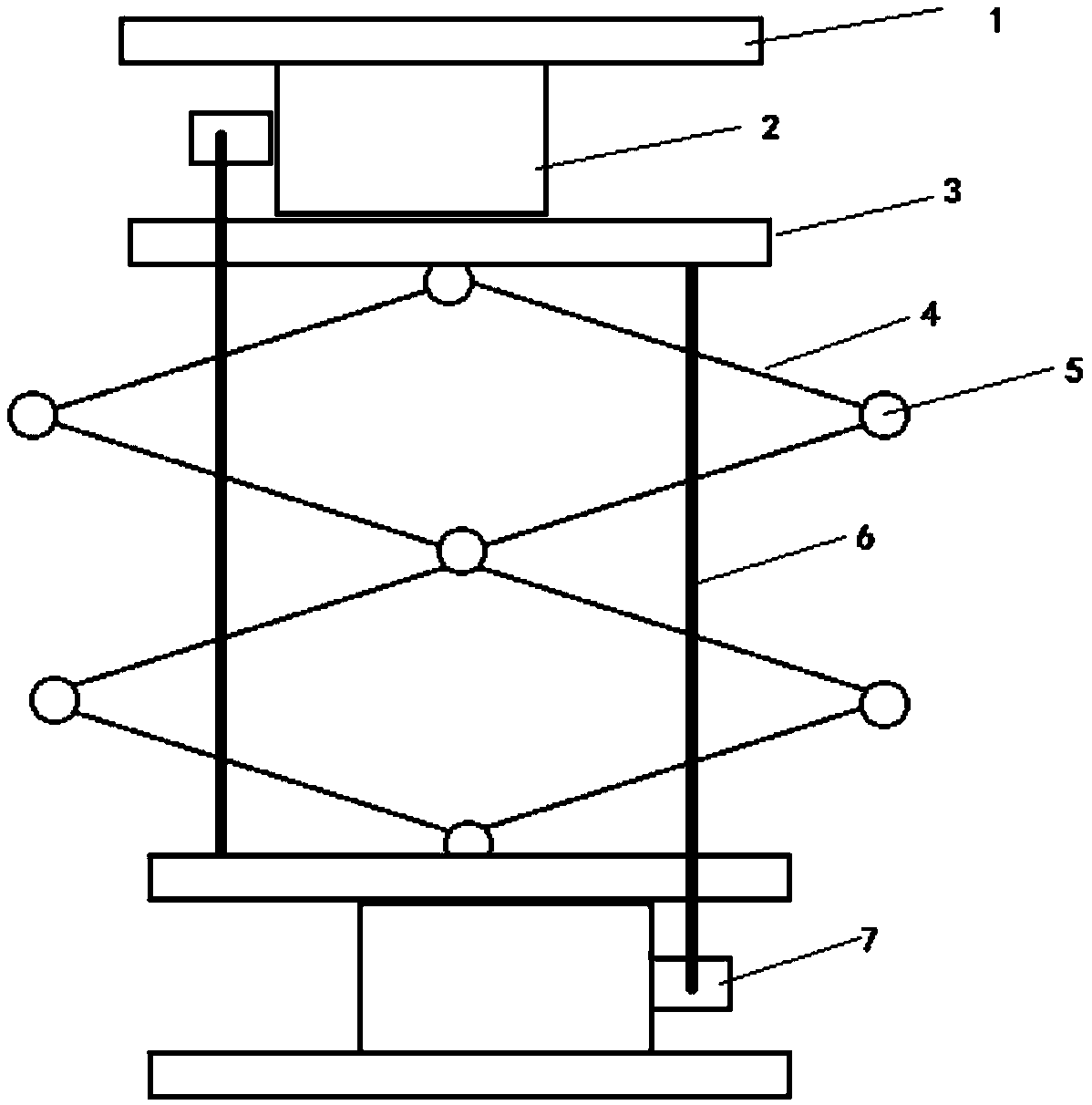

[0012] Such as figure 1 As shown in the telescopic structure shown, the functions of telescopic and bending are mainly realized. The basic principle of the structure is to use the instability of the quadrilateral to apply a force on the opposite corner of the quadrilateral to change the shape of the quadrilateral. If the tension is applied, the quadrilateral can be lengthened. If the pressure is applied, the shape of the quadrilateral can be changed. The quadrilateral is shortened to achieve the compression function. The bending function can be realized by connecting two such quadrilaterals through connectors. In our design, each side of the quadrilateral is made of hard material, and each corner of the quadrilateral has a spring 5 to provide a tendency for the telescopic structure to expand and contract. In this telescopic structure, the functions of the two geared motors 2 are basically similar to the geared motors in the software module 1. When the two geared motors 2 pul...

Embodiment 2

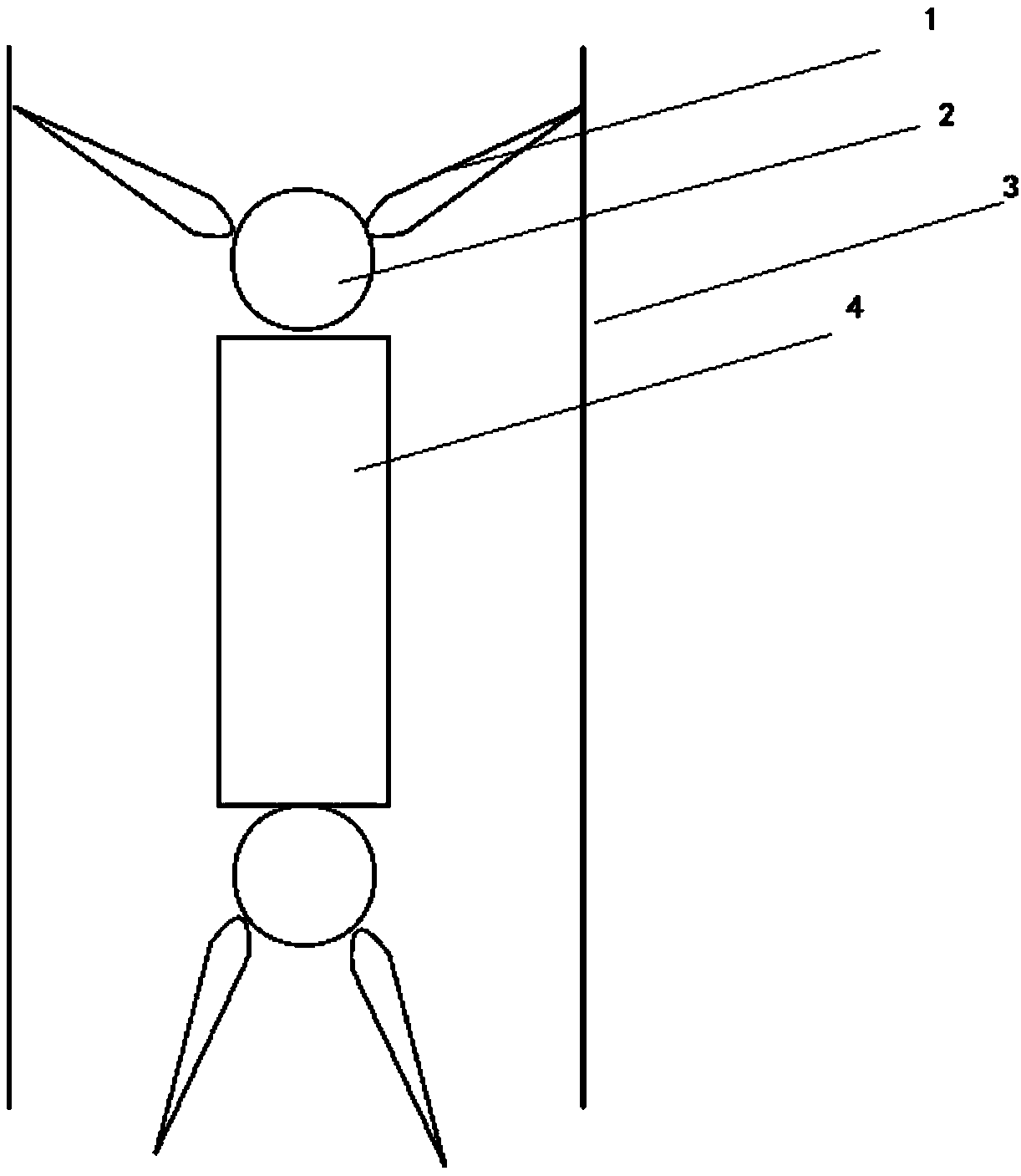

[0014] Such as figure 2 As shown, using the telescopic structure, we have designed a crawling robot on the inner wall of the pipe. The main purpose is to install support grippers 1 at both ends of the telescopic structure. This gripper is similar to the manipulator on the market. to a fixed effect. During our crawling process, the upper support gripper a works to support the inner wall of the pipeline, the lower support gripper b relaxes, and the contraction length of the telescopic structure 4 becomes smaller to lift the lower gripper; then the lower support gripper b Open the support gripper a on the top and draw it in, and stretch the telescopic structure 4 at the same time, so that the support gripper a is lifted, and climbing can be realized by reciprocating like this.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com