Adjusting method and device of heating power, heating load and computer storage medium

A heating power and adjusting device technology, which is applied in the field of heating load and computer storage media, and heating power adjustment, can solve the problems of lower reliability, unadjustable heating load power, and temperature rise of heating components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

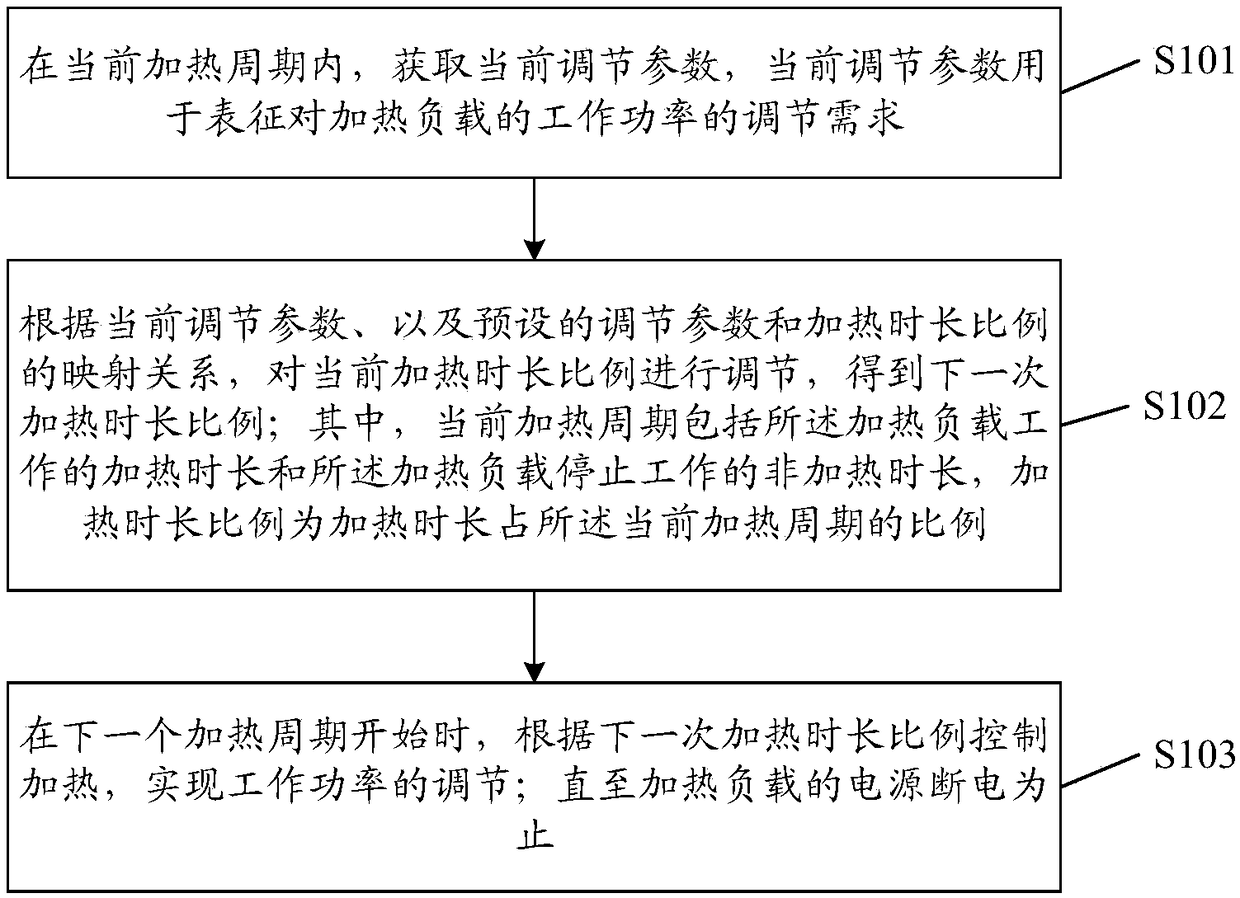

[0046] Embodiment 1 of the present invention provides a heating power adjustment method, which is applied to heating loads. The heating loads can be electric heaters and other equipment. The embodiment of the present invention does not limit the types of heating loads, such as figure 1 As shown, the method includes:

[0047] Step S101: In the current heating cycle, obtain the current adjustment parameter, which is used to represent the adjustment demand for the working power of the heating load.

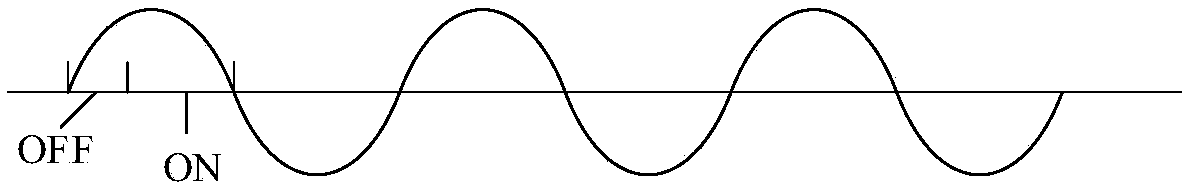

[0048] Exemplarily, the driving mode of the heating load may be a direct current driving mode or an alternating current driving mode, for example, the waveform of the alternating current may be a sine wave, a square wave or a triangular wave; figure 2 It is a schematic diagram of a waveform of alternating current in an embodiment of the present invention, image 3 It is a schematic diagram of another waveform of alternating current in the embodiment of the present invention, figu...

Embodiment 2

[0092] In order to better reflect the purpose of the present invention, further illustrations are given on the basis of the above-mentioned embodiments.

[0093] Embodiment 2 of the present invention provides a heating power adjustment method, which is applied to heating loads. The heating loads can be electric heaters and other equipment, such as Figure 6 As shown, the method includes:

[0094] Step S601: In the current heating cycle, obtain the current ambient temperature, and obtain the current first temperature difference between the current ambient temperature and the preset target temperature, and the current first temperature difference is used to represent the adjustment requirement for the working power.

[0095] In the embodiment of the present invention, the user sets the target temperature when using the heating load, and the processor controls the temperature sensor to obtain the current ambient temperature, and calculates the current first temperature difference...

Embodiment 3

[0105] In order to better reflect the purpose of the present invention, further illustrations are given on the basis of the above-mentioned embodiments.

[0106] Embodiment 3 of the present invention provides a heating power adjustment method, which is applied to heating loads. The heating loads can be electric heaters and other equipment, such as Figure 7 As shown, the method includes:

[0107] Step S701: In the current heating cycle, receive a power value, the power value is used to represent the adjustment requirement for the working power.

[0108] In the embodiment of the present invention, when using the heating load, the user can input a function instruction through the power selection key or the electrical gear selection key, and the function instruction is used to indicate the working power of the heating load required by the user.

[0109] Step S702: According to the received power value, and the mapping relationship between the preset power value and the heating d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com