An expander unit and a pulse-tube type free-piston Stirling refrigerator

A technology for expanders and refrigerators, applied in refrigerators, gas cycle refrigerators, refrigeration and liquefaction, etc., can solve the problems of low efficiency and dissipation of pulse tube refrigerators, eliminate pumping gas losses, and reduce the size of the whole machine Quality, the effect of reducing manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

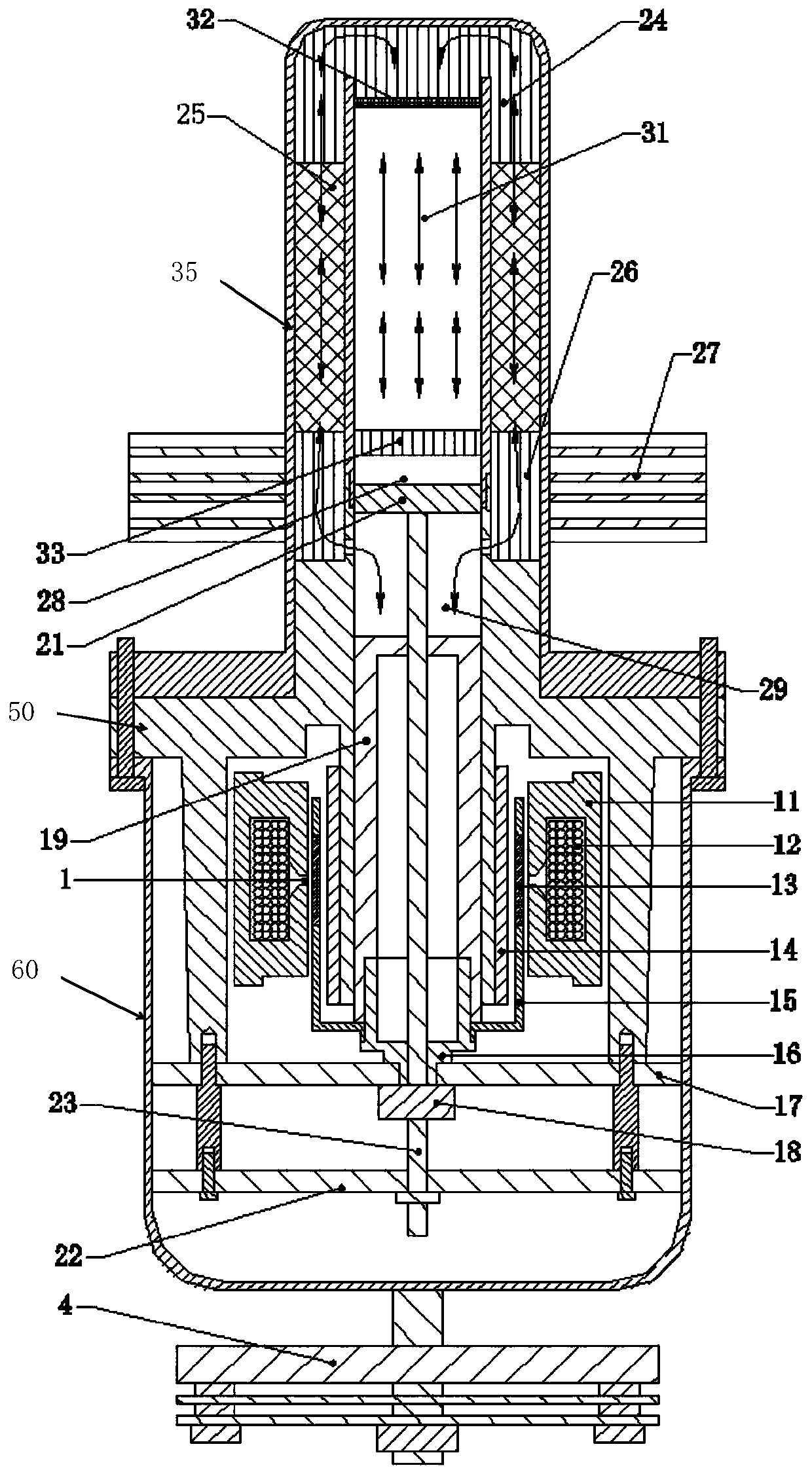

[0030] Such as figure 1 As shown, the coaxial pulse tube type free-piston Stirling refrigerator 100 includes a linear motor 1 , a compression unit, an expander unit, an undamped dynamic vibration absorption unit 4 , a frame 50 , and a casing 60 .

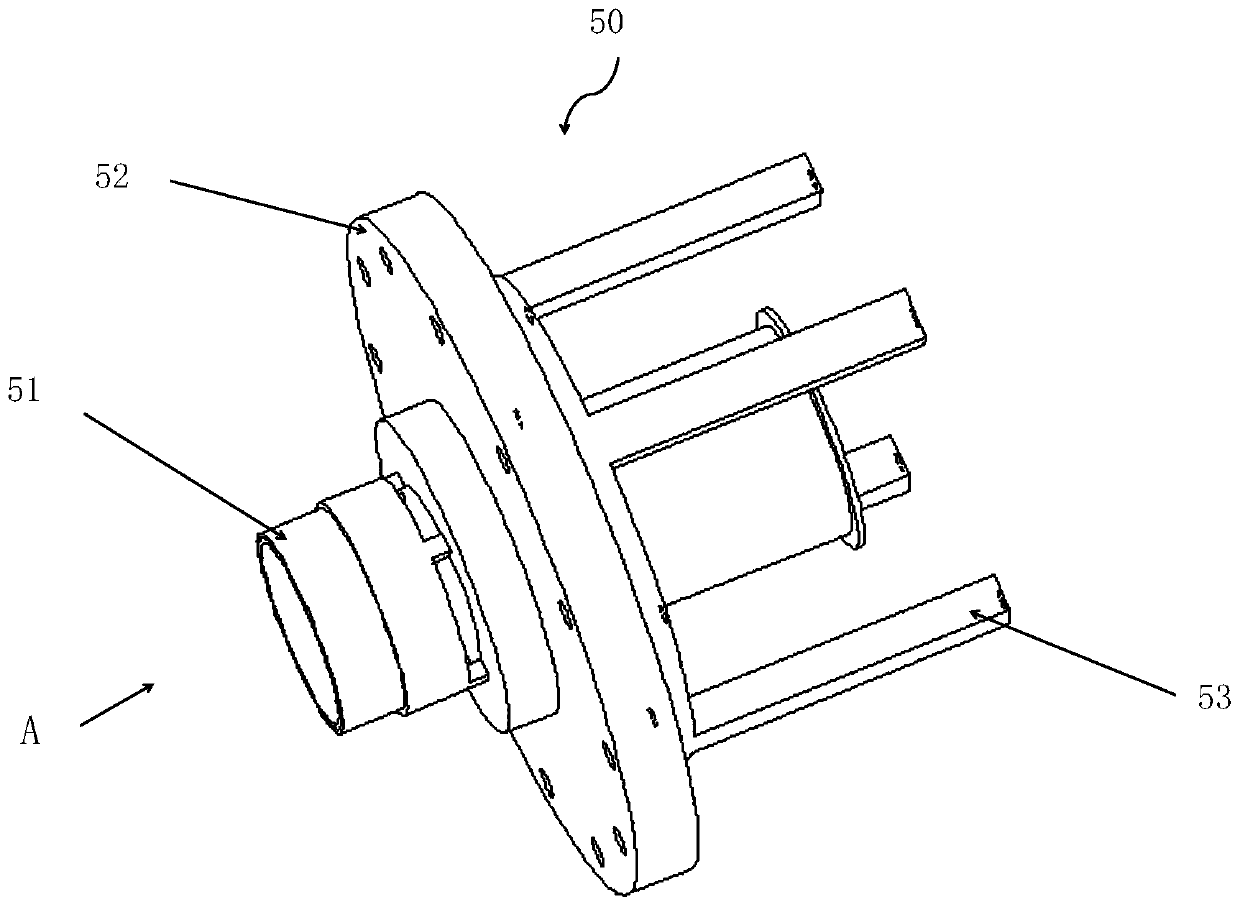

[0031] Such as figure 2 , 3 , 4 and 5, the frame 50 includes a flange 52, a piston tube 51 and a base 53 arranged in the flange 52,

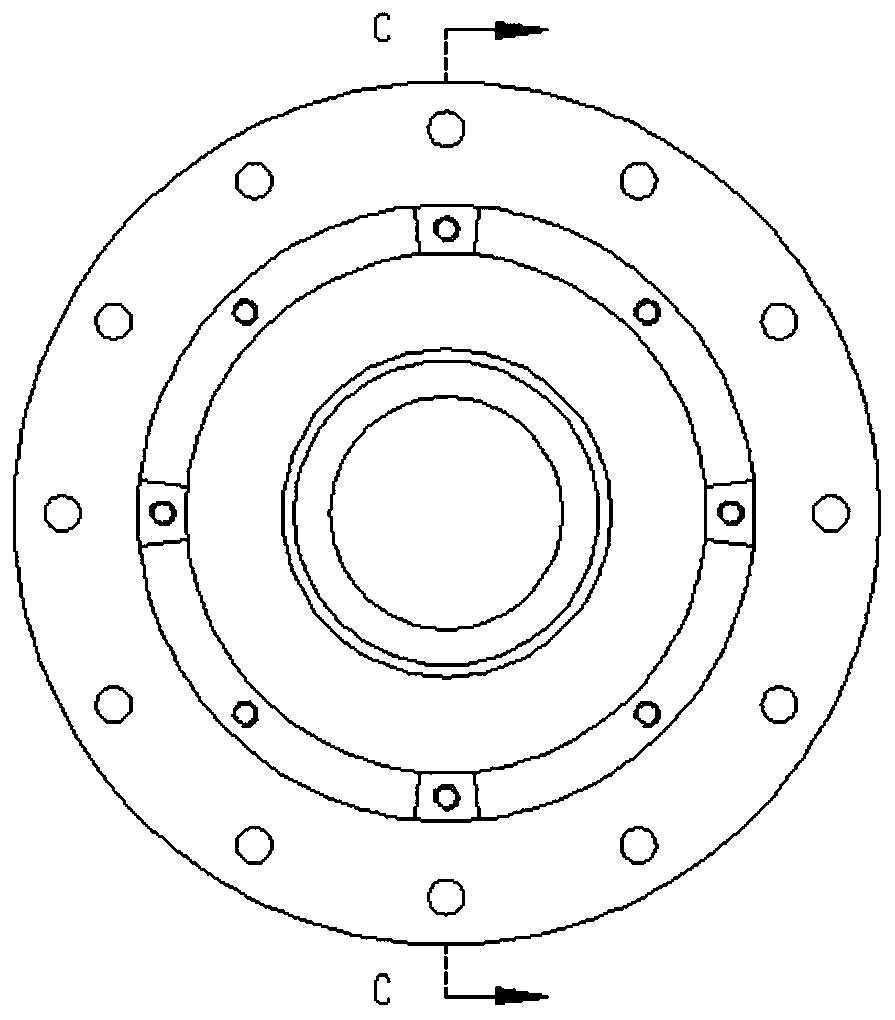

[0032] Wherein, the flange 52 is in the shape of a disk, and a concentric small disk 521 is arranged on one side of the flange, and a plurality of connecting through holes are uniformly arranged on the flange 52 .

[0033] The base 53 is cylindrical, one end is connected to one side of the flange 52, and the other end is a free end. The centerline of the base 53 coincides with the centerline of the flange 52, and the free end of the base 53 is provided with a plurality of connecting screw holes. In an embodiment, the base 53 is four legs arranged around the centerline of the flange 52 .

[0034] ...

Embodiment 2

[0059] The other structure of this embodiment is the same as that of Embodiment 1, except that it also includes a radiator 27 located on the outside of the first-stage hot-end heat exchanger 26 and arranged on the shell, and the first-stage hot-end heat exchanger 26 passes heat through the outer shell Passed to the radiator 27 on the outside, finally released to the environment.

Embodiment 3

[0061] The other structure of this embodiment is the same as that of the second embodiment, except that it also includes a deflector 32 arranged at one end of the pulse tube and located inside the pulse tube, and the deflector 32 is connected with the cold end heat exchanger 24 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com