Frozen food material efficient unfreezing cabinet and unfreezing method implemented through same

A high-efficiency, food-based technology, applied in the field of thawing, can solve the problems of long thawing time, mutual odor, different heating amount, etc., and achieve the effect of increasing the heat exchange area, increasing the thawing speed, and improving the thawing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

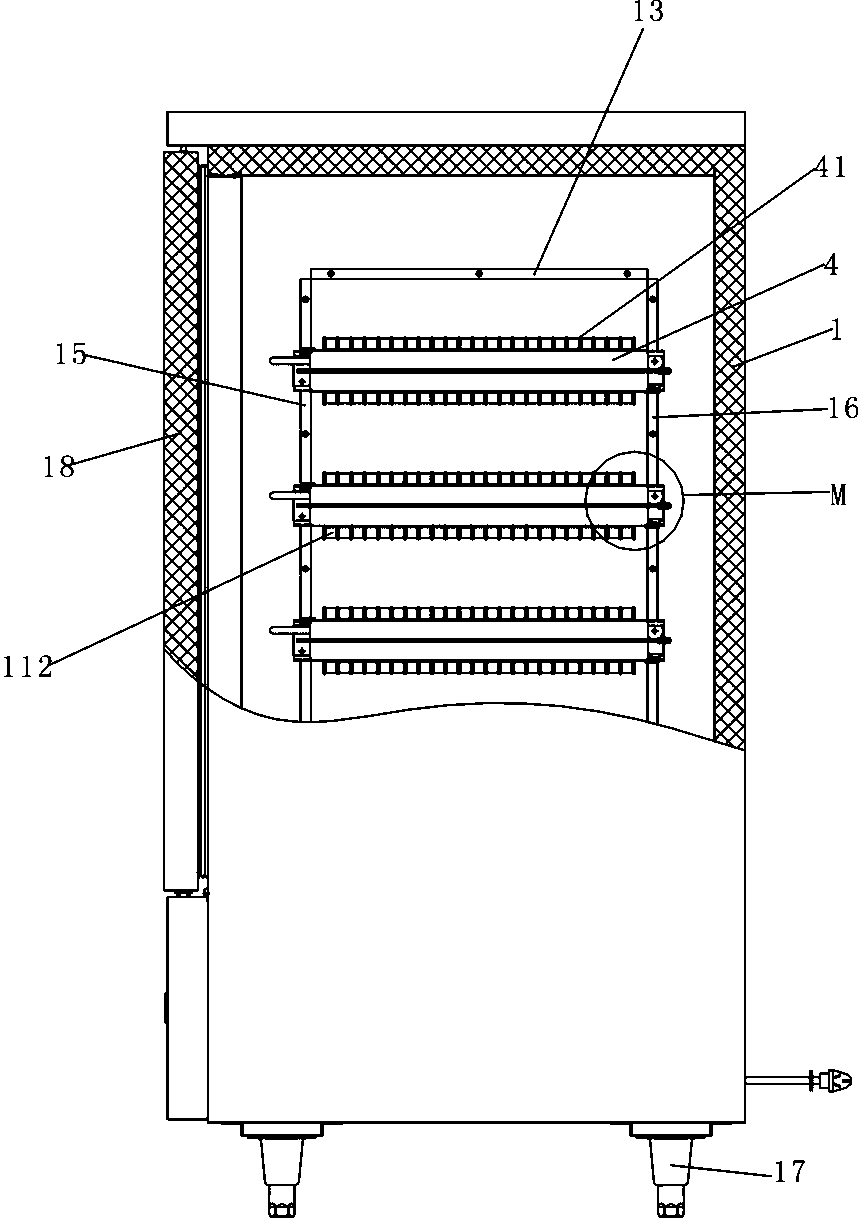

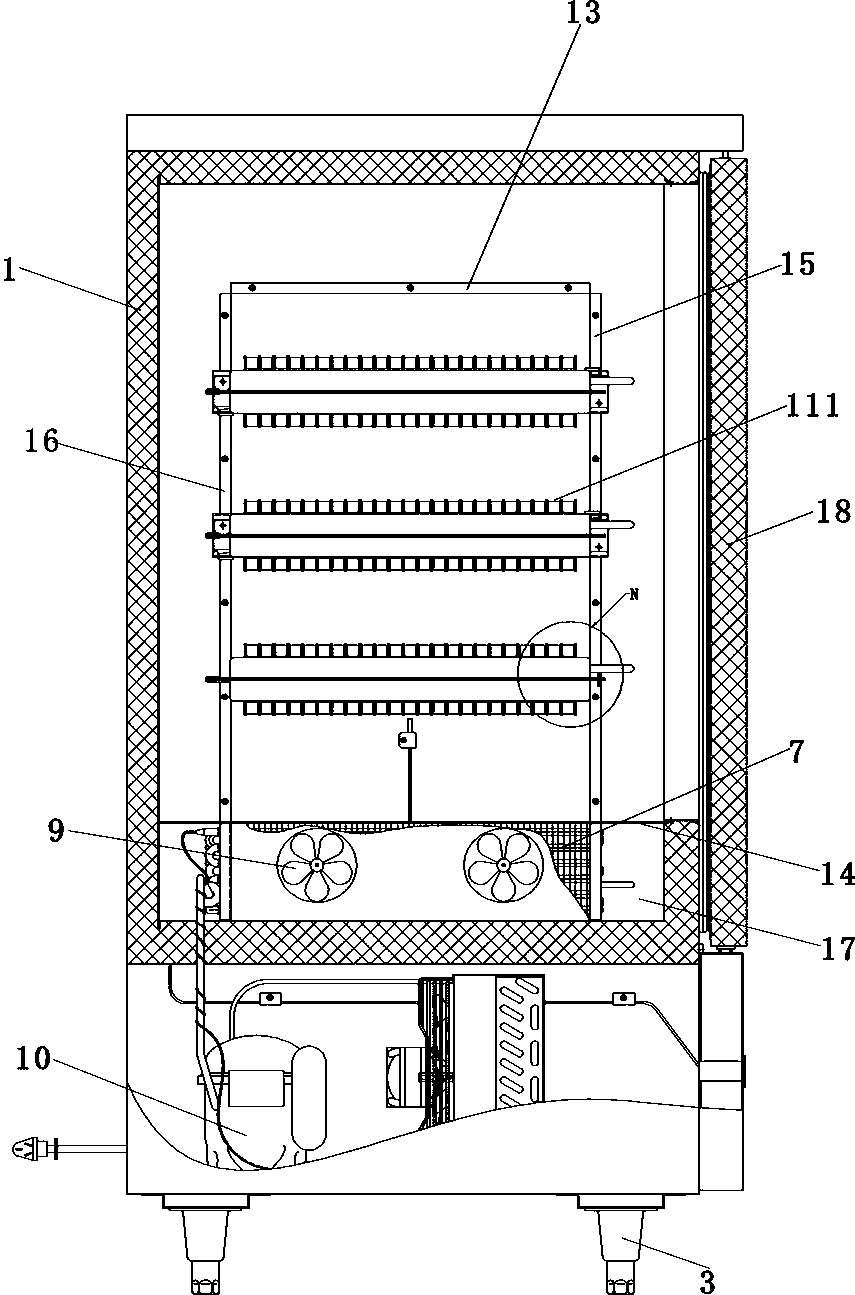

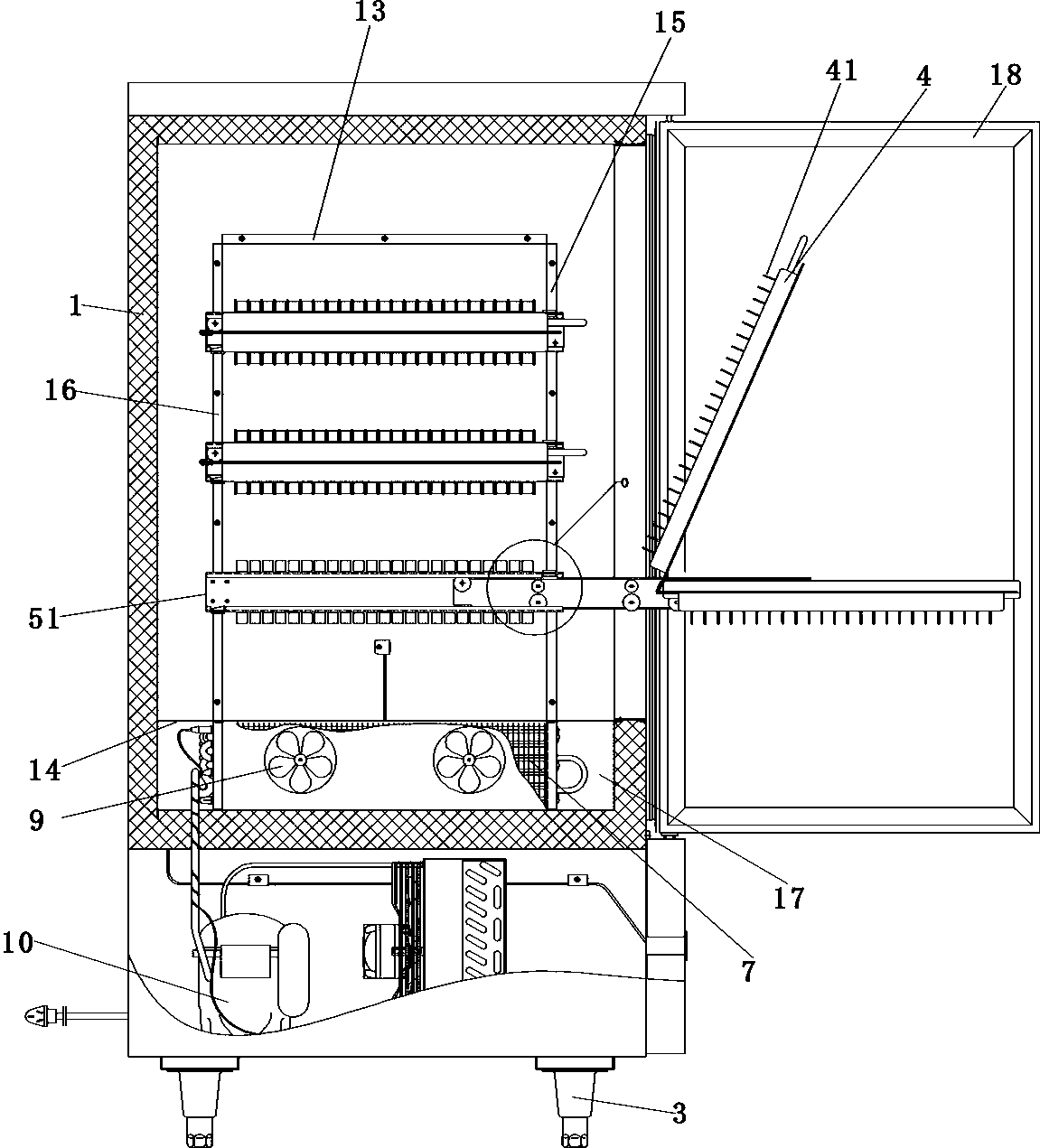

[0042] Such as figure 1 , 2 , 3, and 4, the high-efficiency thawing cabinet for frozen food materials of the present invention includes a cabinet body. The upper part of the cabinet body is an insulated box body 1, the lower part is a control room 2, and the bottom is provided with supporting feet 3; Frame, the left and right sides of the frame are fixed with the air outlet channel plate 11 and the return air channel plate 12, the upper and lower sides and the front and rear sides are fixed with the sealing plates 13, 14, 15, 16, the air outlet channel plate is provided with the air outlet hole 111, and the return The air duct plate is provided with a return air hole 112 corresponding to the position of the air outlet hole. The left and right sides of the upper sealing plate are extended and fixed on the left and right side walls of the insulation box, and the front and rear sides of the lower sealing plate are extended and fixed on the front and rear of the insulation box. S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com