An energy-saving black tea drying furnace

A technology for drying furnace and dark tea, applied in drying, drying machine, drying solid materials and other directions, can solve the problems of wasting staff's time for taking tea, reducing the processing efficiency of dark tea, increasing staff's burden, etc. The effect of saving the time of taking tea, being heated quickly and fully, and improving the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

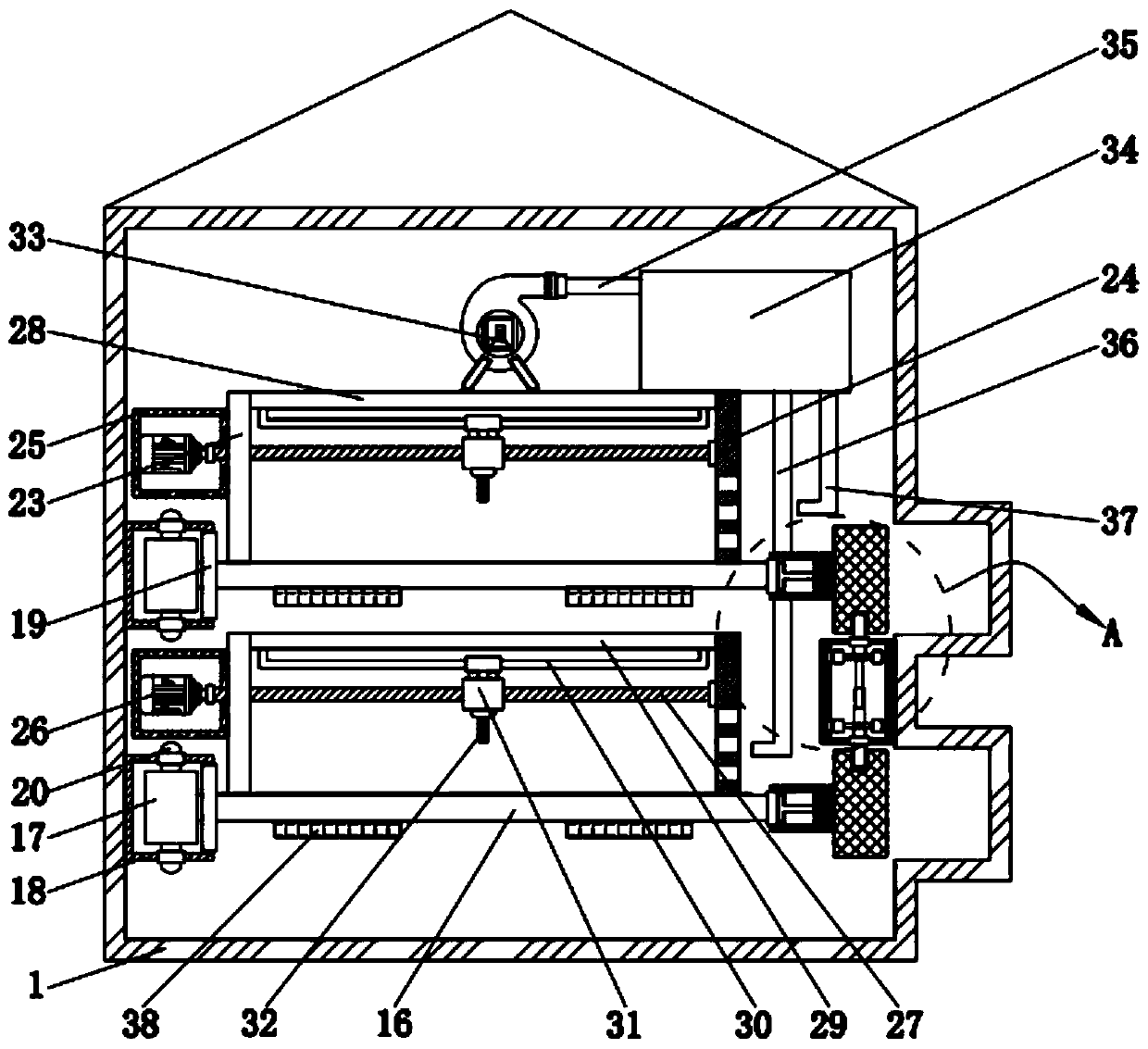

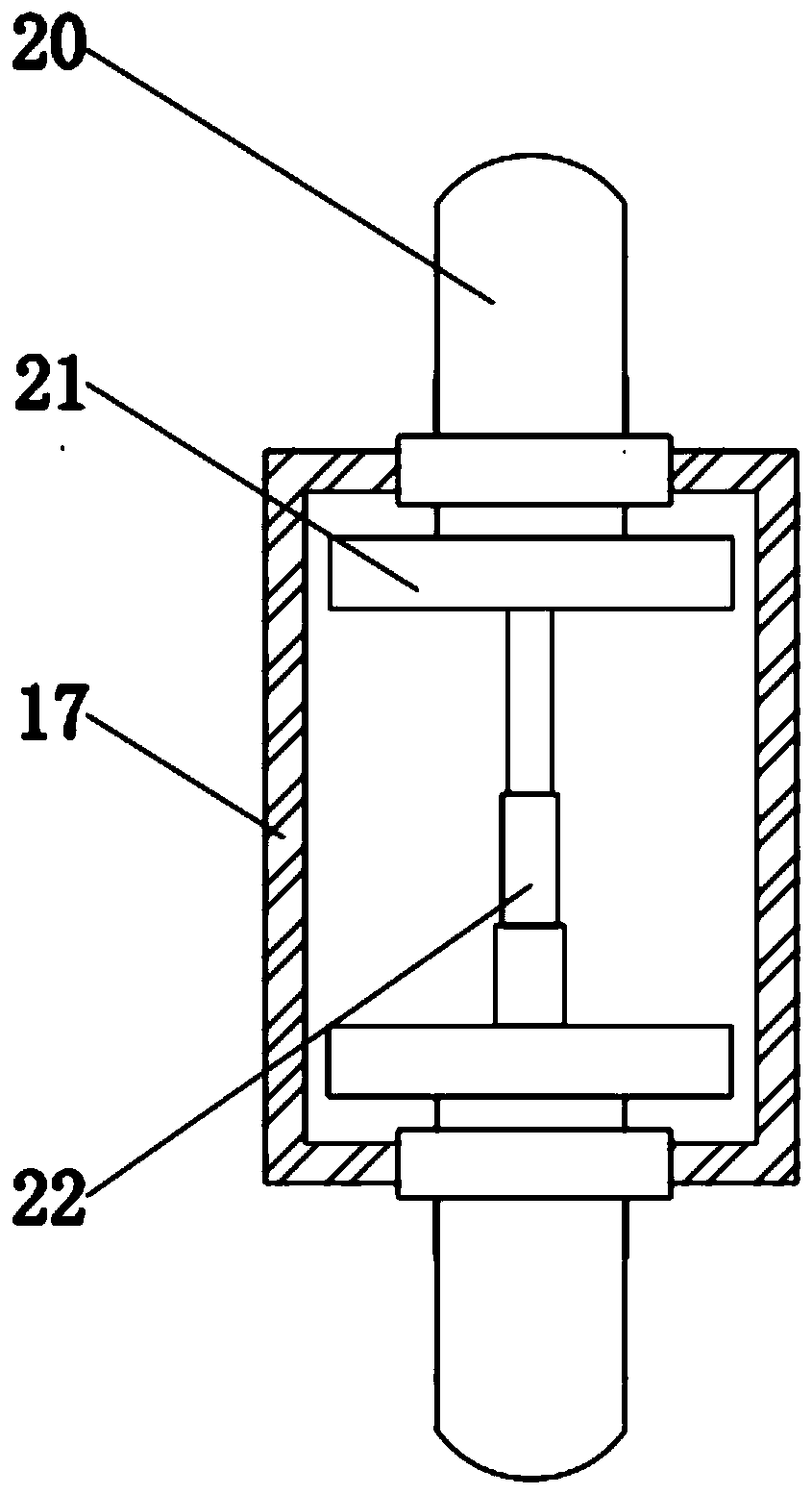

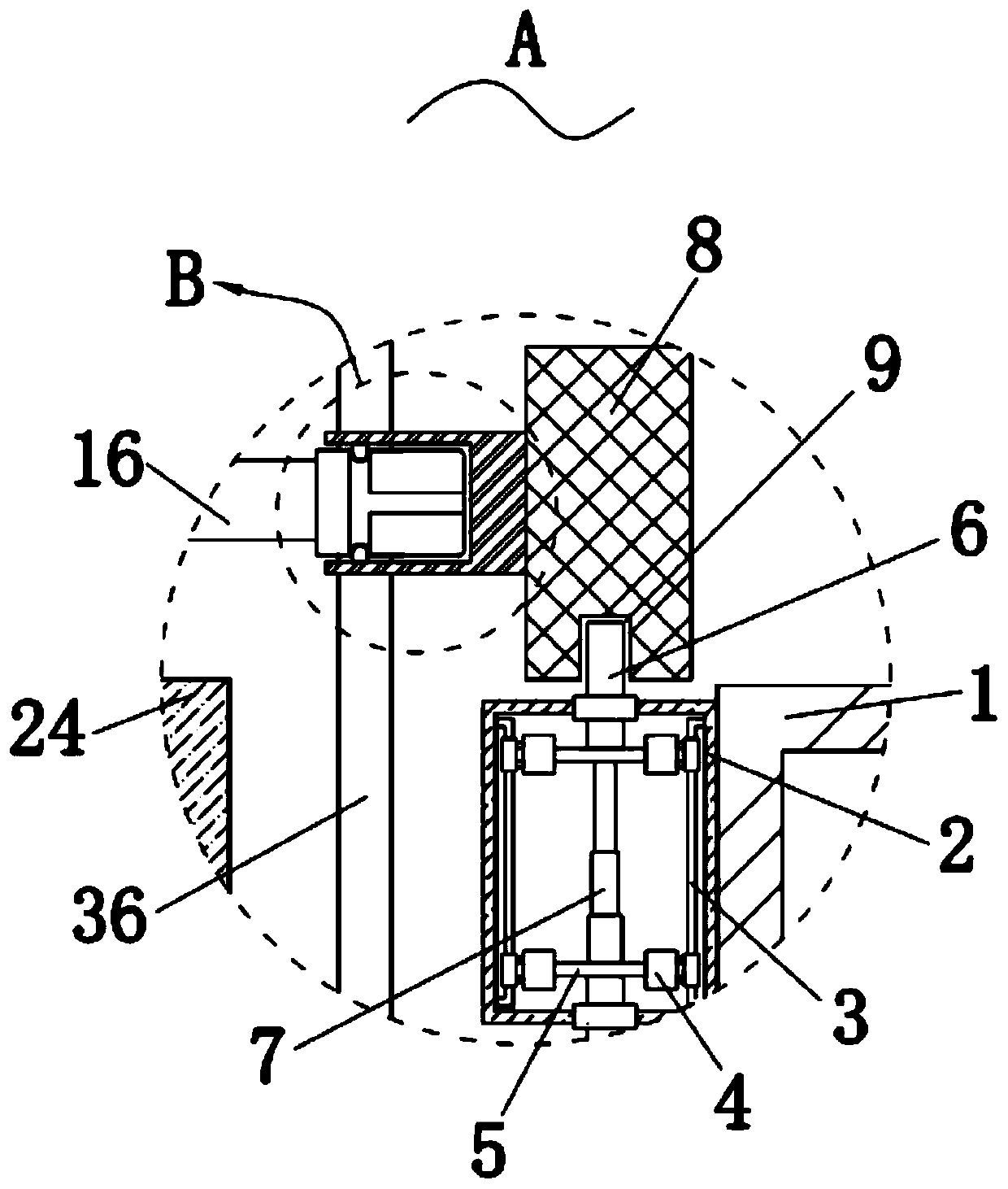

[0039] Please refer to figure 1 , figure 2 , image 3 and Figure 4 ,in, figure 1 A schematic structural view of a preferred embodiment of the energy-saving black tea drying furnace provided by the present invention; figure 2 for figure 1 Structural sectional view of the shown card box structure; image 3 for figure 1 Partial enlarged view of part A shown; Figure 4 for image 3The partial enlarged view of part B is shown. The energy-saving dark tea drying furnace includes: a drying room body 1; a fixed box 2, which is fixed on one side of the inner wall of the drying room body 1; first slide rails 3, the number of the first slide rails 3 There are two, and the two first slide rails 3 are respectively fixed on both sides of the inner wall of the fixed box 2; the first slider 4, the number of the first slider 4 is four, and the first slider ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com