Method for measuring volatile organic compounds released by bag

A technology of organic compounds and determination methods, applied in the field of determination of volatile organic compounds released in bags, can solve the problems of high detection cost, lack of overall evaluation of samples, operator health and environmental hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

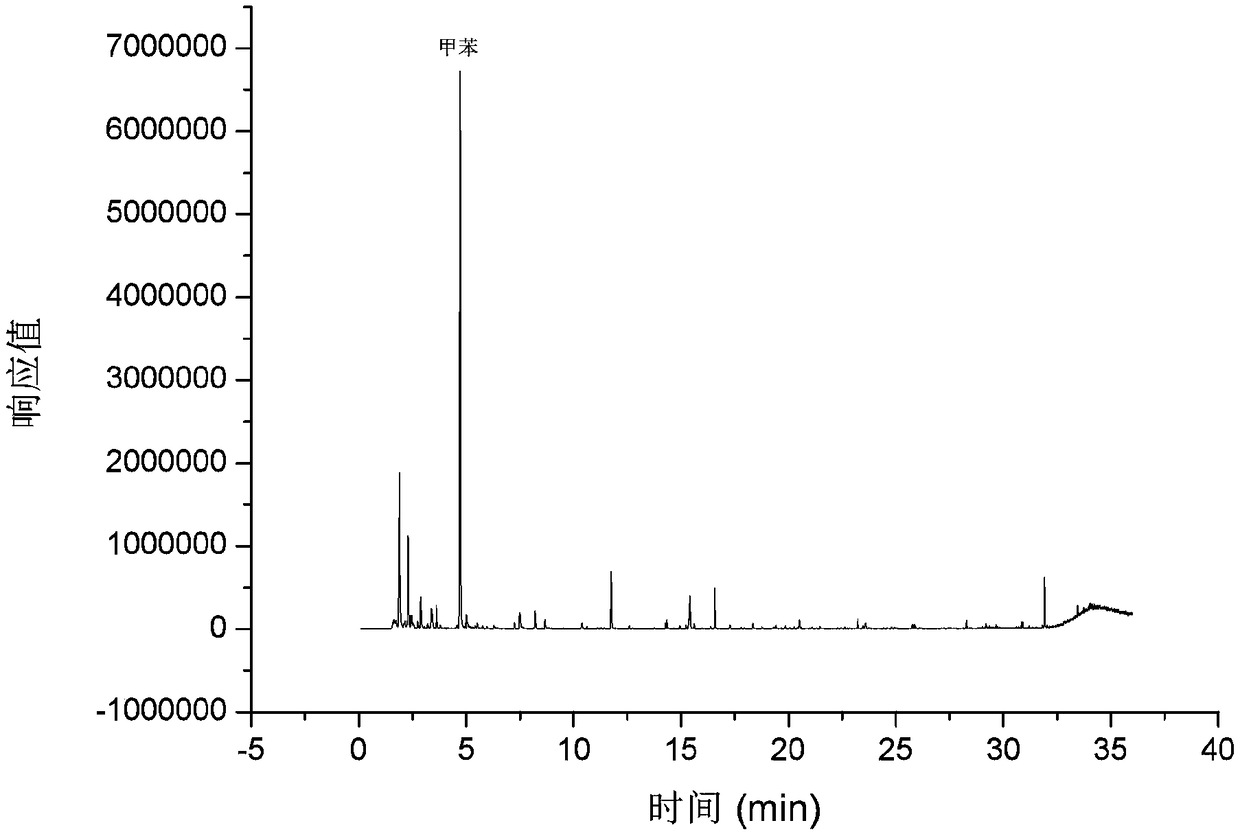

Embodiment 1

[0042] A method for the determination of releasable volatile organic compounds in bags provided in this embodiment comprises the following steps:

[0043] 1. Sampling

[0044] The sample to be tested in the present embodiment is blue children's backpack (volume is about 24L), this backpack is put into the polyvinyl fluoride sampling bag of 50L volume, seals with sealing strip, and sampling bag is provided with interface valve. Fill the sampling bag with the sample sealed with pure nitrogen, the filling volume is 30% of the capacity of the sampling bag, and then use the pump to evacuate the gas, repeating 2-3 times. Then fill it with 20L of pure nitrogen at an ambient temperature of 25±2°C, close the interface valve, and seal the sampling bag. Take another blank sampling bag without putting the sample to be tested, and perform the above steps as a control. Place the two sampling bags in a constant temperature environment chamber at 70±2°C for heating and keep for 4 hours. At...

Embodiment 2

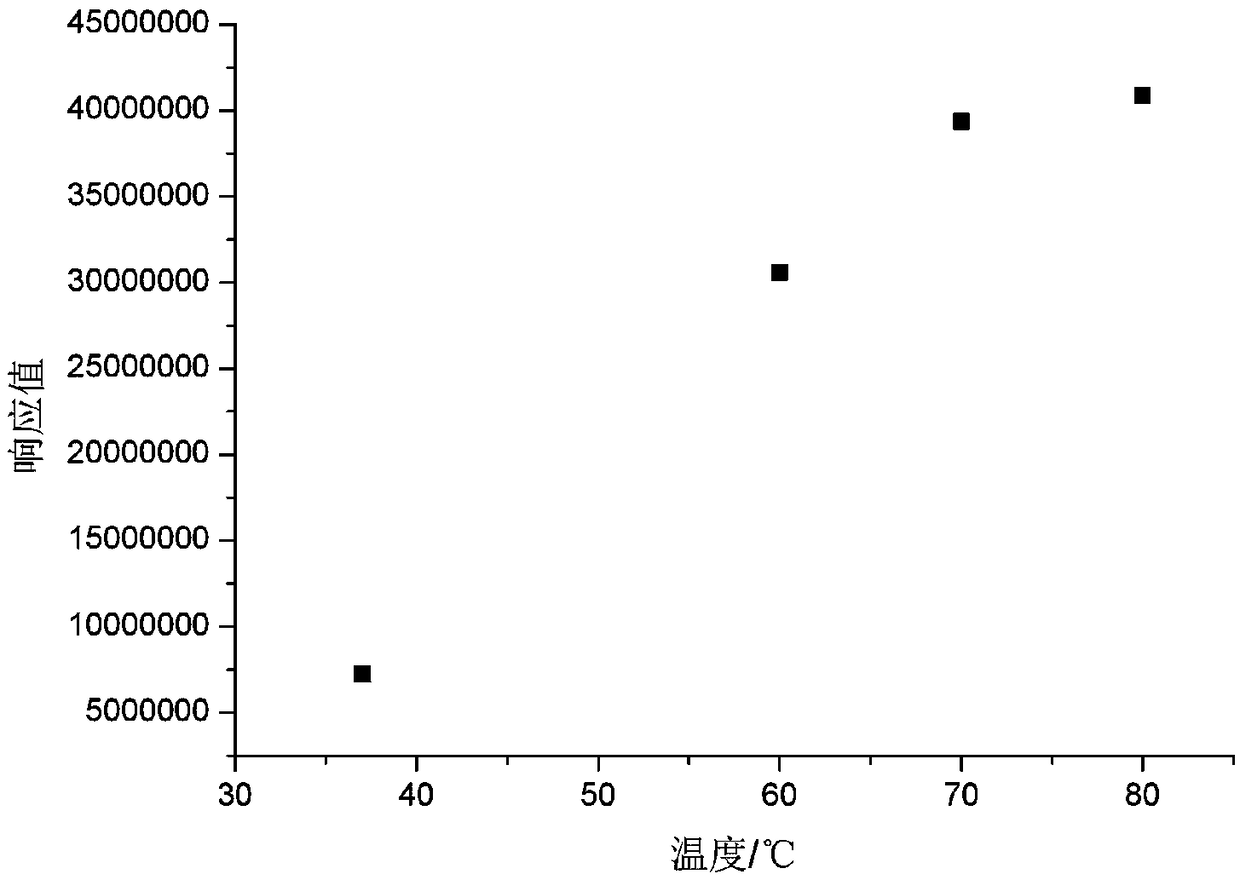

[0087] The influence of embodiment 2 sample processing temperature on test result

[0088] Detect according to the method of embodiment 1, just change the heating temperature in the constant temperature environment chamber, other steps and method are all the same as embodiment 1. That is, the samples to be tested were processed at 37° C., 60° C., 70° C., and 80° C. respectively, and the processing time was the same as in Example 1. Test results such as figure 2 As shown, the results show that the higher the temperature, the greater the release of volatile organic compounds. When the treatment temperature rises to 70°C, the release of volatile organic compounds is basically complete; when the treatment temperature is 80°C, the bags will fade 70°C is the optimal heating treatment temperature, taking into account the time required for detection and the accuracy of the test results, as well as not causing damage to the sample to be tested, and reducing the consumption of samplin...

Embodiment 3

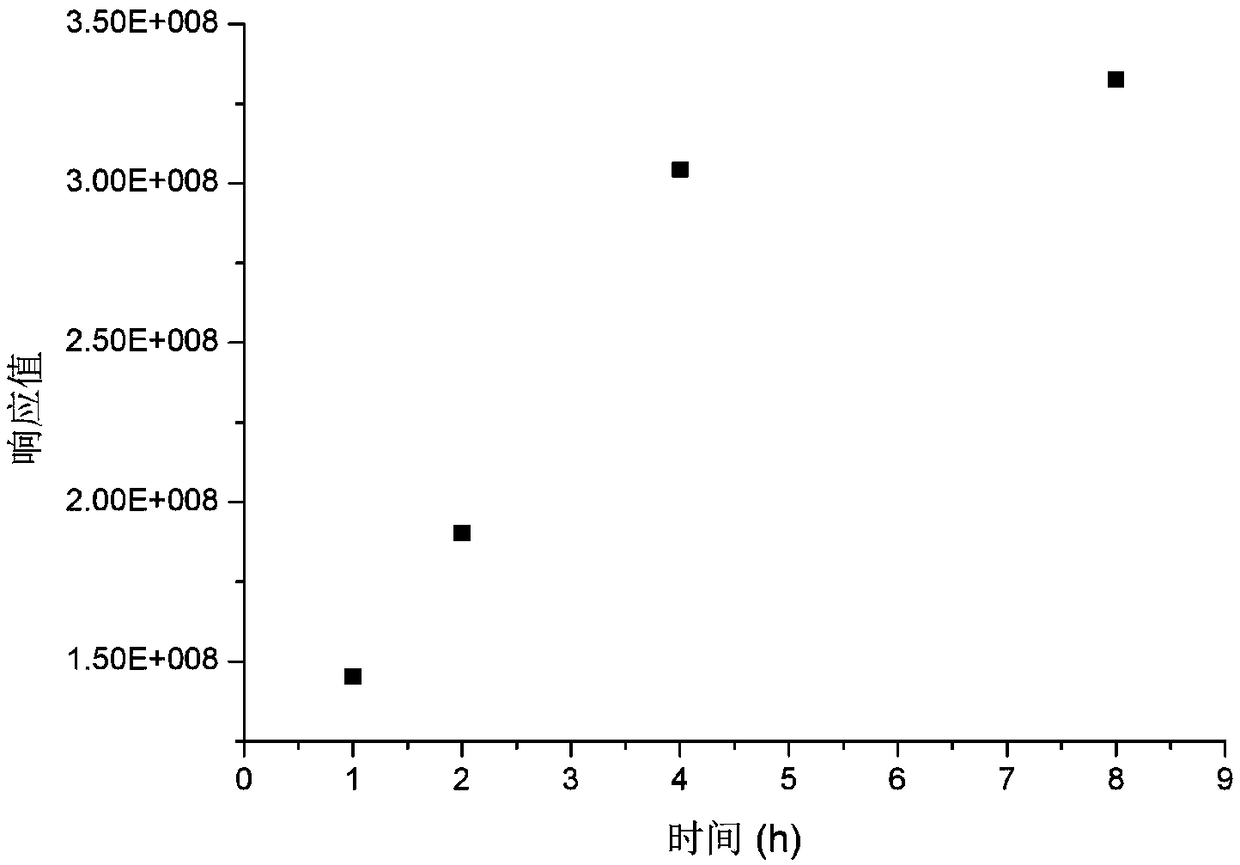

[0089] Example 3 The impact of sample processing time on test results

[0090] Detect according to the method of embodiment 1, just change the time of heat treatment in the constant temperature environment cabin, other steps and method are all the same as embodiment 1. That is to say, the sampling bags were kept in a constant temperature environment chamber at 70°C for 1h, 2h, 4h and 8h. Test results such as image 3 As shown, the results show that: the longer the sample is heat-treated, the greater the release of volatile organic compounds, and the release will basically not increase after 4 hours. Considering the detection efficiency and detection accuracy, the heat treatment time of the sample is 4h is the best choice.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionization energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com