Device and method for measuring electromagnetic parameter of material in microwave heating process

An electromagnetic parameter and microwave heating technology, which is applied in the direction of measuring device, magnetic property measurement, dielectric property measurement, etc., can solve the problems that cannot be used to measure the electromagnetic parameters of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

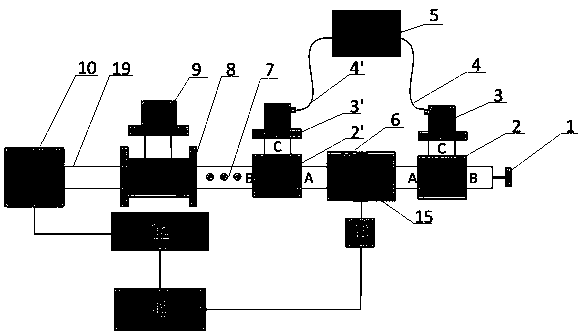

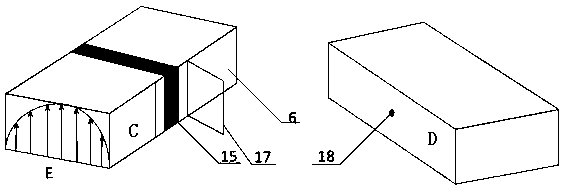

[0031] Such as Figure 1-3 As shown.

[0032] A device for measuring electromagnetic parameters of materials in a microwave heating process, the device includes a microwave heating system and an electromagnetic parameter measuring system; the microwave heating system includes a microwave single-mode resonant cavity 6 and a microwave source 10, the microwave single-mode resonant cavity 6 The two ends are respectively connected to the A terminal of the first waveguide switch 2' and the second waveguide switch 2, the B terminal of the first waveguide switch 2' is connected to the adapter 7, the adapter 7 is connected to the circulator 8, and the circulator 8 is connected to the The water load 9 is connected to the microwave source 10 through the waveguide transmission line 19 on the other hand; the B terminal of the second waveguide switch 2 is connected to the terminal adapter 1, and the material 15 is placed in the microwave single-mode resonant cavity 6 for microwave heating; ...

Embodiment 3

[0043] Measurement of electromagnetic parameters of epoxy resin during microwave heating. The first waveguide switch 2' and the second waveguide switch 2 adopt an electromagnetic control method. Use the following steps to test the electromagnetic parameters of epoxy resin during microwave heating,

[0044] The first step is to adjust the first waveguide switch 2' and the second waveguide switch 2 so that the A terminal and the C terminal are connected, and the remaining ports are short-circuited to form an electromagnetic parameter measurement system, and the entire electromagnetic parameter measurement system is calibrated;

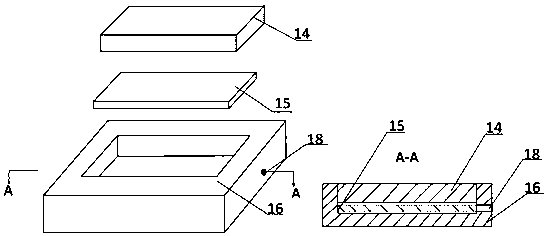

[0045] In the second step, epoxy resin 15 is poured into the groove 16 of the sample holder and sealed with a cover plate 14 . The sample fixture is made of high temperature-resistant and wave-transparent polytetrafluoroethylene, and the outer dimension is 86 (length) × 43 (width) × 20 (thickness) mm 3 , the internal groove size is 80 (length) × 38 (wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com