Molybdenum disulfide-coated lithium nickel cobalt manganate composite material, and preparation method and application thereof

A technology of nickel cobalt lithium manganate and composite materials, applied in the field of lithium ion batteries, can solve the problems of structural damage of positive electrode active materials, reduced capacity of main material, discount of coating effect, etc., to achieve electrochemical performance improvement, reduction of capacity loss, Easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 0.325g ammonium tetrathiomolybdate ((NH 4 ) 2 MoS 4 ) was dissolved in 32.5g of absolute ethanol, heated and stirred in a water bath at 50°C for 10 minutes to obtain a dispersion; 0.8 co 0.1 mn 0.1 o 2 The ternary material obtains a mixed solution, keeps stirring in a 50°C water bath until the solvent dries up, then vacuum-dries the resulting product at 90°C to obtain a mixture, and sinters it at 400°C under an argon atmosphere for 6 hours to obtain LiNi 0.8 co 0.1 mn 0.1 o 2 @MoS 2 Composite materials, where MoS 2 The coating amount is 2wt%.

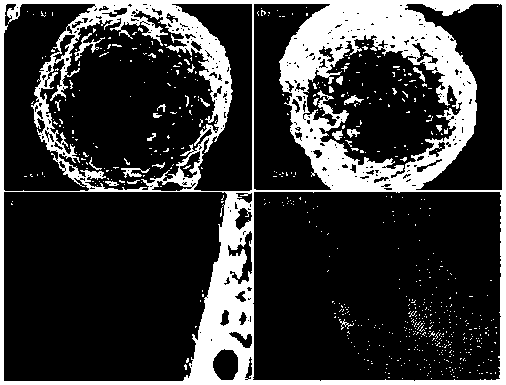

[0048] figure 1 Be LiNi in embodiment 1 0.8 co 0.1 mn 0.1 o 2 Ternary materials, and LiNi 0.8 co 0.1 mn 0.1 o 2 @MoS 2 Scanning and transmission electron microscopy images of the composite material; by figure 1 (a) and (b), it can be seen that the morphology of the material after modification basically does not change, and they are all spherical particles, indicating that the coating process will not damage t...

Embodiment 2

[0052] 0.65g ammonium tetrathiomolybdate ((NH 4 ) 2 MoS 4 ) was dissolved in 100g of ethylene glycol solvent, heated and stirred in a water bath at 60°C for 15 minutes to obtain a dispersion; 0.6 co 0.2 mn 0.2 o 2 For ternary materials, keep stirring in a water bath at 60°C until the solvent is completely evaporated, dry the resulting mixture in vacuum at 100°C, and then sinter at 450°C under an argon atmosphere for 8 hours to obtain molybdenum disulfide (MoS 2 ) surface modified LiNi 0.6 co 0.2 mn 0.2 o 2 @MoS 2 Composite materials, where MoS 2 The coating amount is 4wt%.

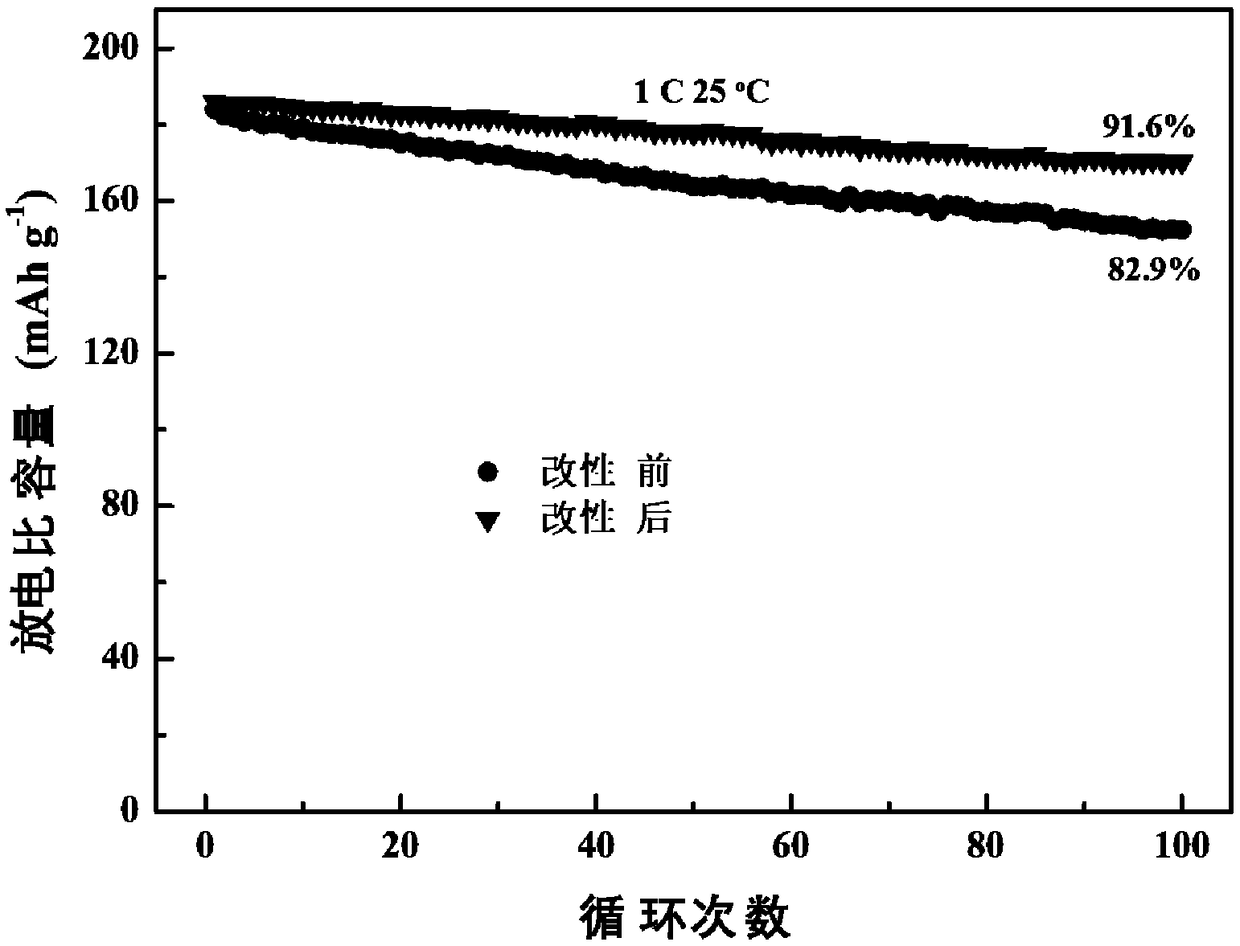

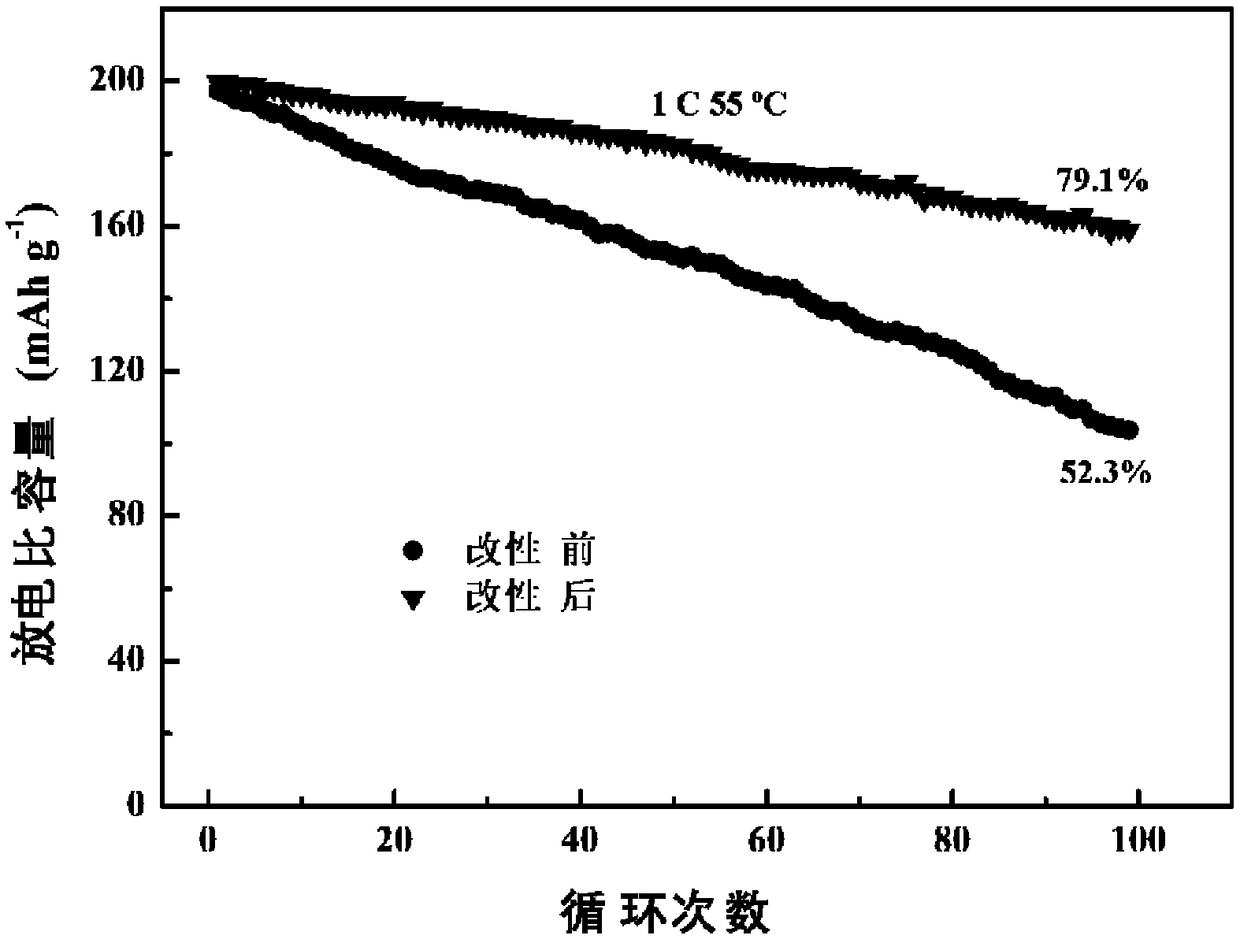

[0053] Figure 4 It is the cycle curve graph of positive electrode ternary material before and after modification under 1C current density, 25°C and 2.8-4.3V voltage range, which is determined by Figure 4 It can be seen that after the material before modification is cycled 100 times at 1C, the capacity of the material increases from 173.1mAh g -1 Rapidly decays to 143.9mAh·g -1 , the capaci...

Embodiment 3

[0055] 0.975g ammonium tetrathiomolybdate ((NH 4 ) 2 MoS 4 ) was dissolved in 50g ethanol solvent, heated and stirred in a water bath at 70°C for 20 minutes to obtain a dispersion; add (average particle size 11μm, 10g) LiNi 0.5 co 0.2 mn 0.3 o 2 For ternary materials, keep stirring in a water bath at 70°C until the solvent dries up, then vacuum-dry the resulting mixture at 120°C, and then sinter at 500°C under a nitrogen atmosphere for 10 hours to obtain molybdenum disulfide (MoS 2 ) surface modified LiNi 0.5 co 0.2 mn 0.3 o 2 @MoS 2 Composite materials, where MoS 2 The coating amount is 6wt%.

[0056] Figure 5 It is the cycle curve graph of positive electrode ternary material before and after modification under 1C current density, 25°C and 2.8-4.3V voltage range, which is determined by Figure 5 It can be seen that after the material before modification is cycled 100 times at 1C, the capacity of the material increases from 159.4mAh g -1 Rapidly decays to 129.6m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com