Green tea processing method capable of realizing better color

A processing method and technology of green tea, applied in tea treatment before extraction, etc., can solve the problems of large chlorophyll damage, poor color of green tea, yellowing or redness of soup, and achieve the goal of reducing cell activity, emerald green color, and avoiding yellowing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

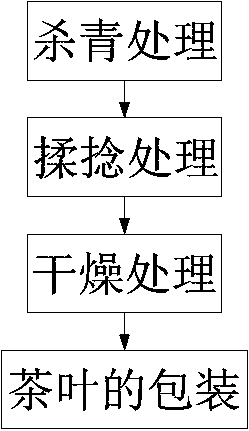

Image

Examples

Embodiment 1

[0025] A kind of green tea processing method with better color and luster, described green tea processing method comprises the steps:

[0026] (1) Finishing treatment

[0027] a. For dehydration of tea leaves, place the picked tea leaves in a cylindrical container with openings at both ends, and the container is in a cool place, and then set blocking filter screens at both ends of the container to block the tea leaves. The inside of the container is blown to dry the tea leaves, so that the water inside the tea leaves can be evaporated, reducing the water content in the tea cells and reducing their activity;

[0028] b. Passivation of enzymes in tea leaves, take out the dehydrated tea leaves, and then pour them into a drum-type degreening machine, control the temperature between 260-320°C, and control the heating time between 3-5min, under the action of high temperature Inactivate enzymes in tea;

[0029] (2) Kneading treatment

[0030] a. To cool the tea leaves, place the g...

Embodiment 2

[0043] A kind of green tea processing method with better color and luster, described green tea processing method comprises the steps:

[0044] (1) Finishing treatment

[0045] a. For dehydration of tea leaves, place the picked tea leaves in a cylindrical container with openings at both ends, and the container is in a cool place, and then set blocking filter screens at both ends of the container to block the tea leaves. The inside of the container is blown to dry the tea leaves, so that the water inside the tea leaves can be evaporated, reducing the water content in the tea cells and reducing their activity;

[0046] b. Deactivation of enzymes in tea leaves. Take out the dehydrated tea leaves and pour them into an iron pot. Enzyme inactivation in

[0047] (2) Kneading treatment

[0048] a, the cooling of tealeaves, the tealeaves after finishing treatment is flattened and placed on the bamboo sieve, and the filter screen that blocks tealeaves is arranged on the top, and bambo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com