Improved production technology for fructus lycii soft sweets

A production process and fudge technology, which is applied in the confectionery industry, confectionery, sugary food ingredients, etc., can solve the problems of eating trouble, the taste and function of the fudge, and easy to stick to the teeth, etc., and solve the problem of sticking to the teeth. , Satisfy food requirements and improve the effect of sticking teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

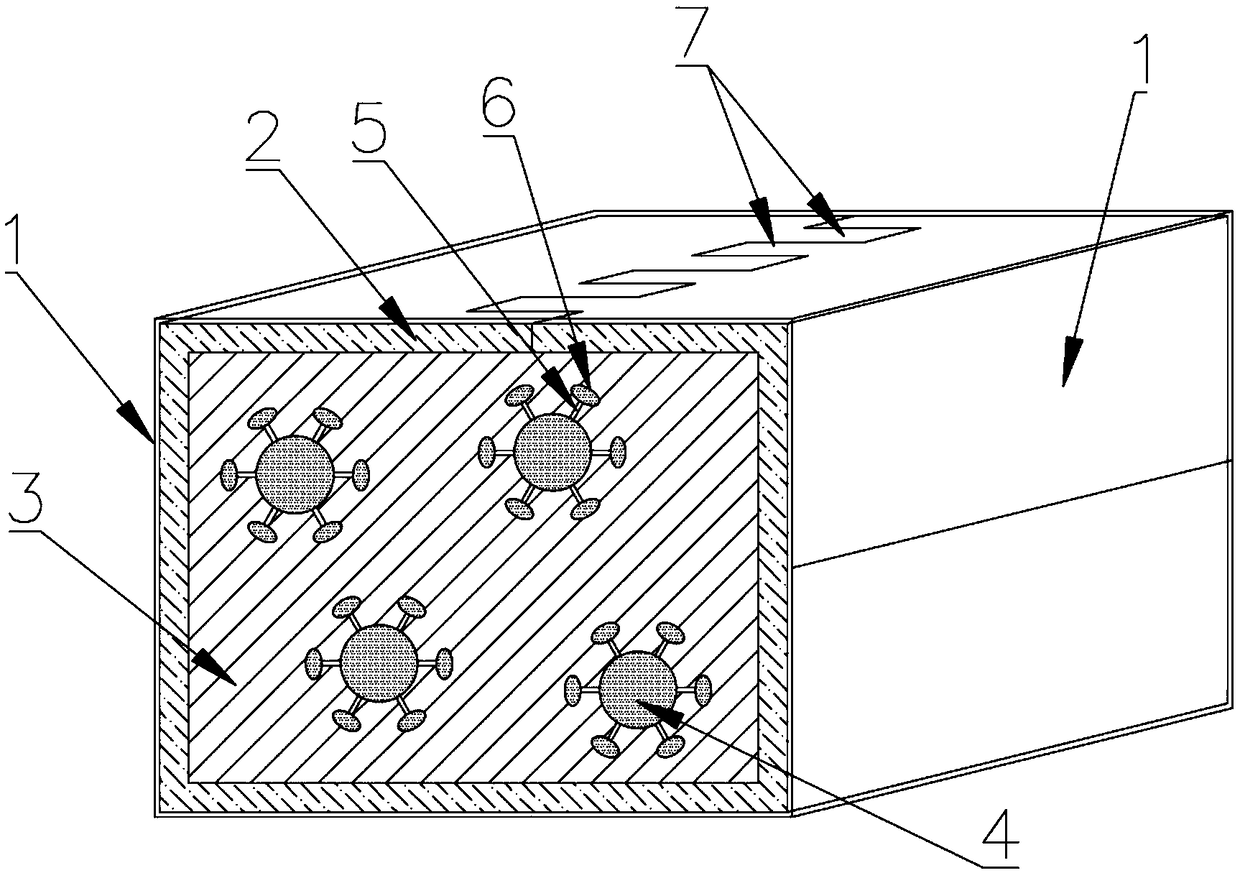

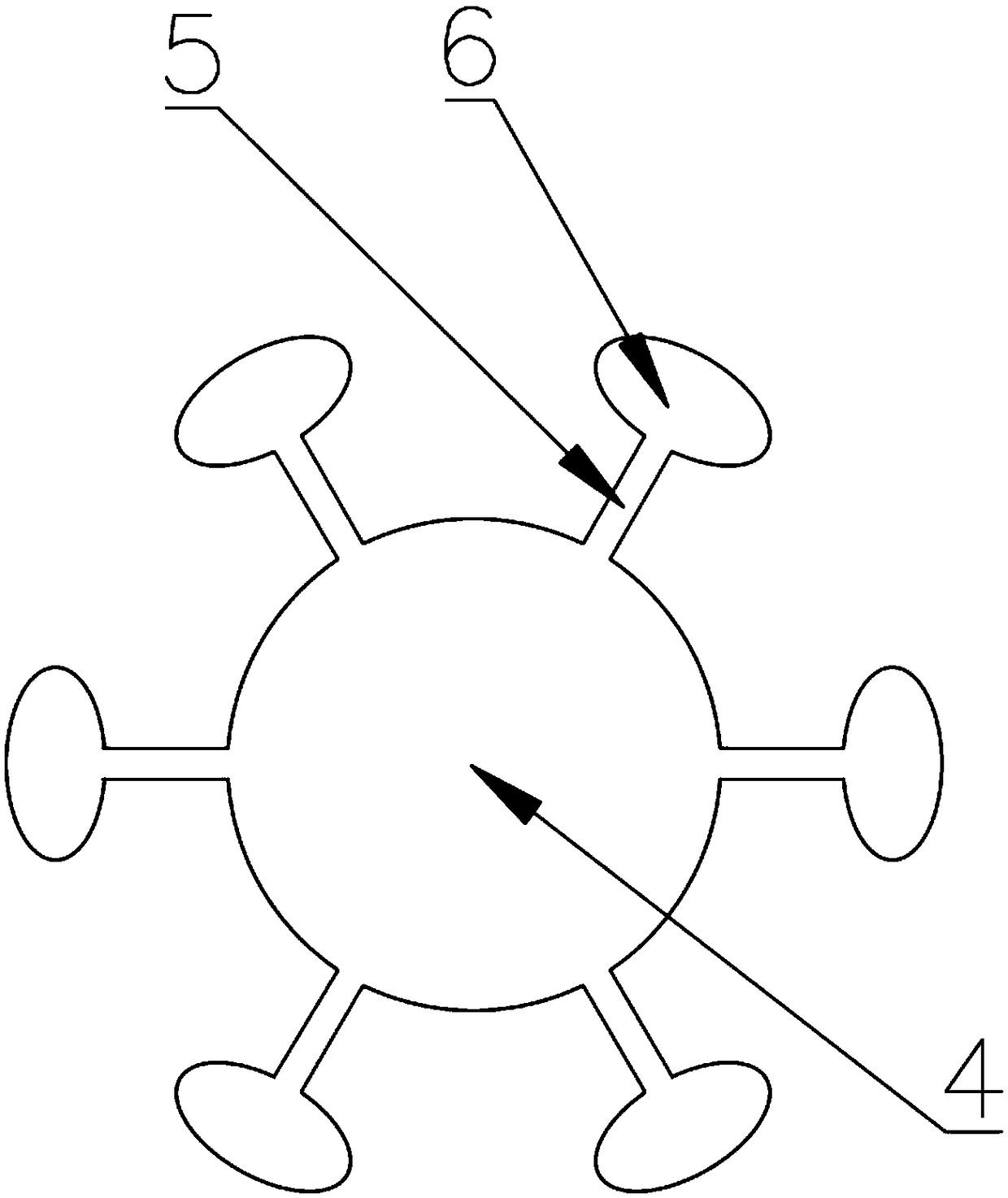

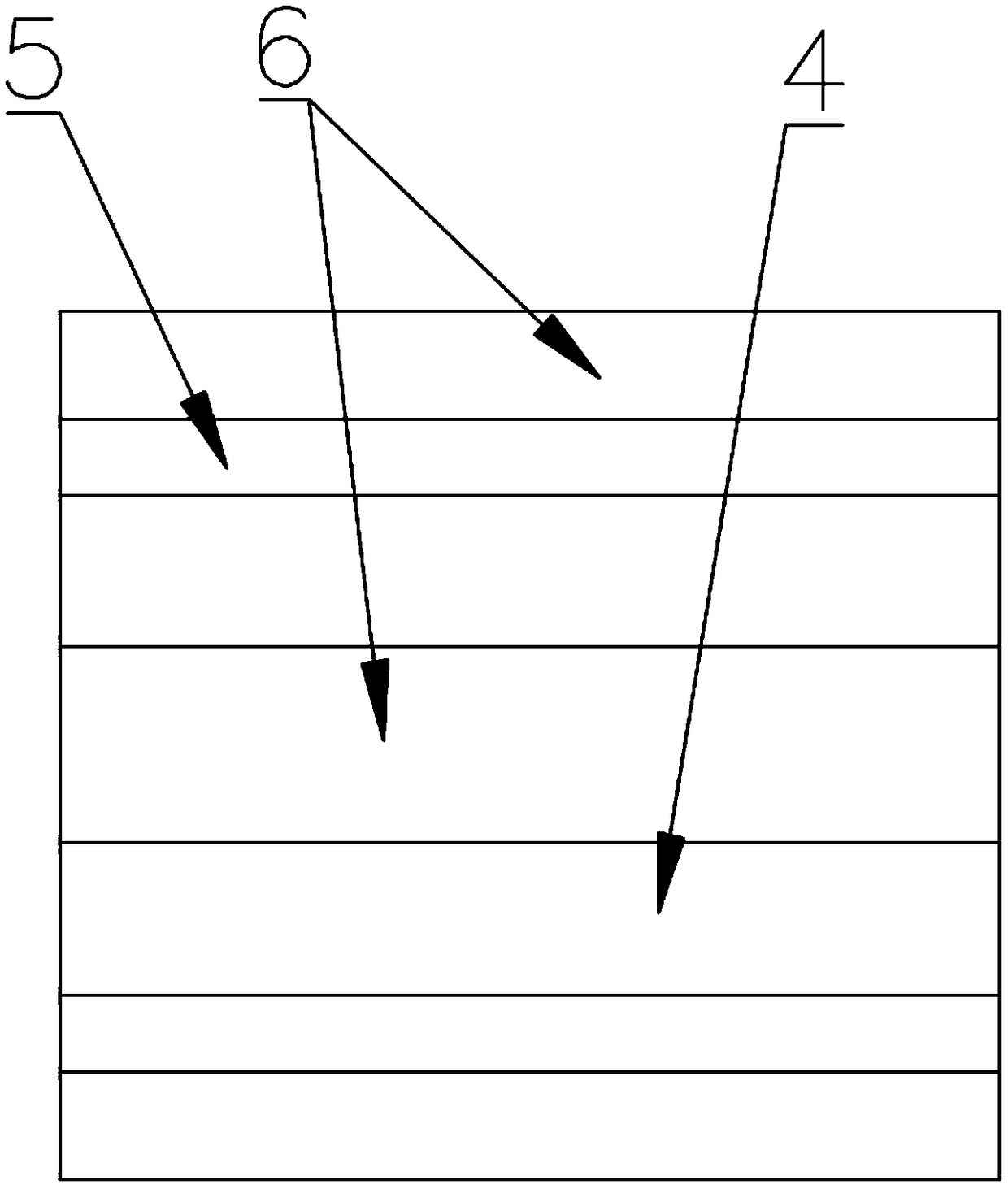

[0027] Example 1, such as Figure 1-3 Shown:

[0028] An improved production process of wolfberry jelly candy, comprising the following specific steps:

[0029] S1: Raw material preparation: Candy raw materials are prepared according to the mass parts as follows: 50 parts of starch, 30 parts of solid tablet, 15 parts of Cornus officinalis, 15 parts of wolfberry pulp, 0.1 part of crystalline cellulose, 5 parts of gum, 12 parts of pectin, 3 parts of Rosa roxburghii pulp, 5 parts of cherry pulp, 5 parts of banana pulp, 2 parts of citric acid, 2 parts of spices;

[0030] S2: Preparation of soft candy base material: the 50 parts of starch include 20 parts of starch treated with amylomaltase and 30 parts of non-crosslinked starch; in the preparation process, first prepare 100 parts of water by mass, and heat the water After boiling, adjust the water temperature to 55°C-60°C, add the 20 parts by mass of the starch treated with amylomaltase and the 30 parts of non-crosslinked starch...

specific Embodiment 2

[0043] According to the preparation process in Example 1, the prepared goji berry jelly candy shows good health care effect after long-term consumption. For example, Mr. Jiao from Wuhan, Hubei, is 51 years old this year. He was weak and suffered from renal dysfunction. After buying the wolfberry jelly candy prepared by this process and taking it for 2 months, the physical and mental state is obviously improved, and the kidney function is better improved and recovered. At the same time, according to Mr. Jiao’s feedback, the wolfberry jelly candy of the present application has a good tooth-sticking performance during the eating process. During the eating process, the jelly can seldom adhere to the teeth, which effectively solves the current gelatin-based problem. The problem of sticking teeth in the preparation of soft candy.

[0044] At the same time, during the specific preparation process of the wolfberry soft candy of the present application, one or more of the banana pulp,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com