Polymer multi-core fiber tube based filter and application thereof

A multi-core fiber and polymer technology, applied in applications, smoke oil filter elements, food science, etc., can solve problems such as difficult to achieve rapid cooling of smoke, limited contact area between materials and smoke, and small stacking density, so as to improve filtration The effect of contacting and exchanging the specific surface of the device with the flue gas, increasing the heat exchange rate, and reducing the instantaneous temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

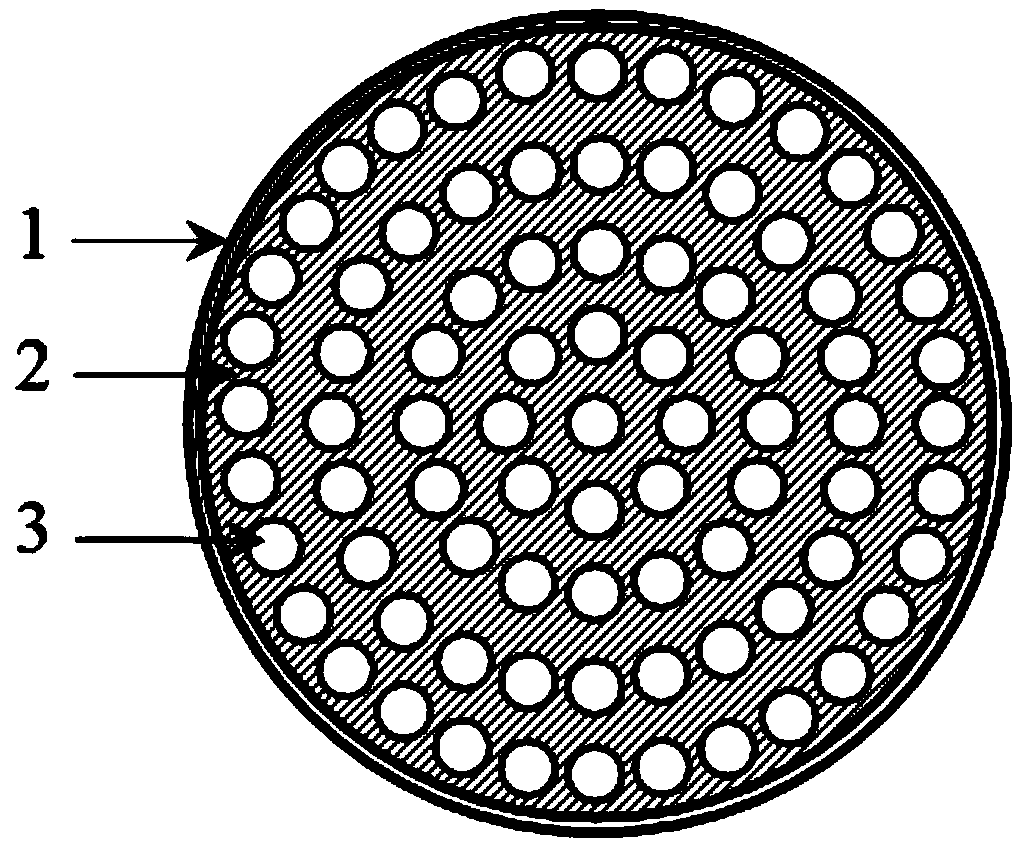

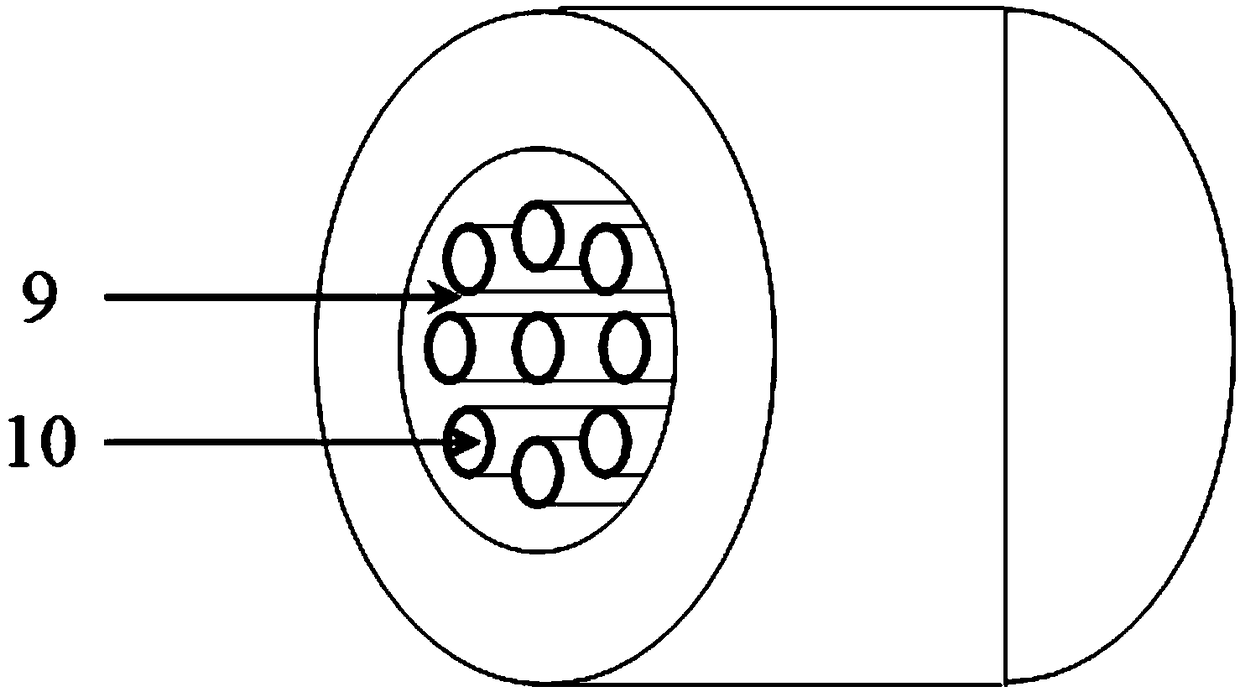

[0034] Such as figure 1 As shown, a filter based on a polymer multi-core fiber tube is formed by wrapping a polypropylene multi-core fiber tube with cigarette paper to form a cylindrical rod with a length of 2 mm. The diameter of the polypropylene multi-core fiber tube is 7.8 mm, the inner diameter of the hole is 0.1 mm, and the volume of the hole accounts for 80% of the volume of the multi-core fiber tube.

[0035] The preparation steps of polypropylene multi-core fiber tube are:

[0036] (1) Putting polypropylene into a screw extruder, and continuously melting and extruding thermoplastic resin through a spinneret at 180°C;

[0037] (2) The primary multi-core fiber tube obtained above was gradually cooled, stretched 20 times, heat-set at 100° C. and cut to obtain a polypropylene multi-core fiber tube.

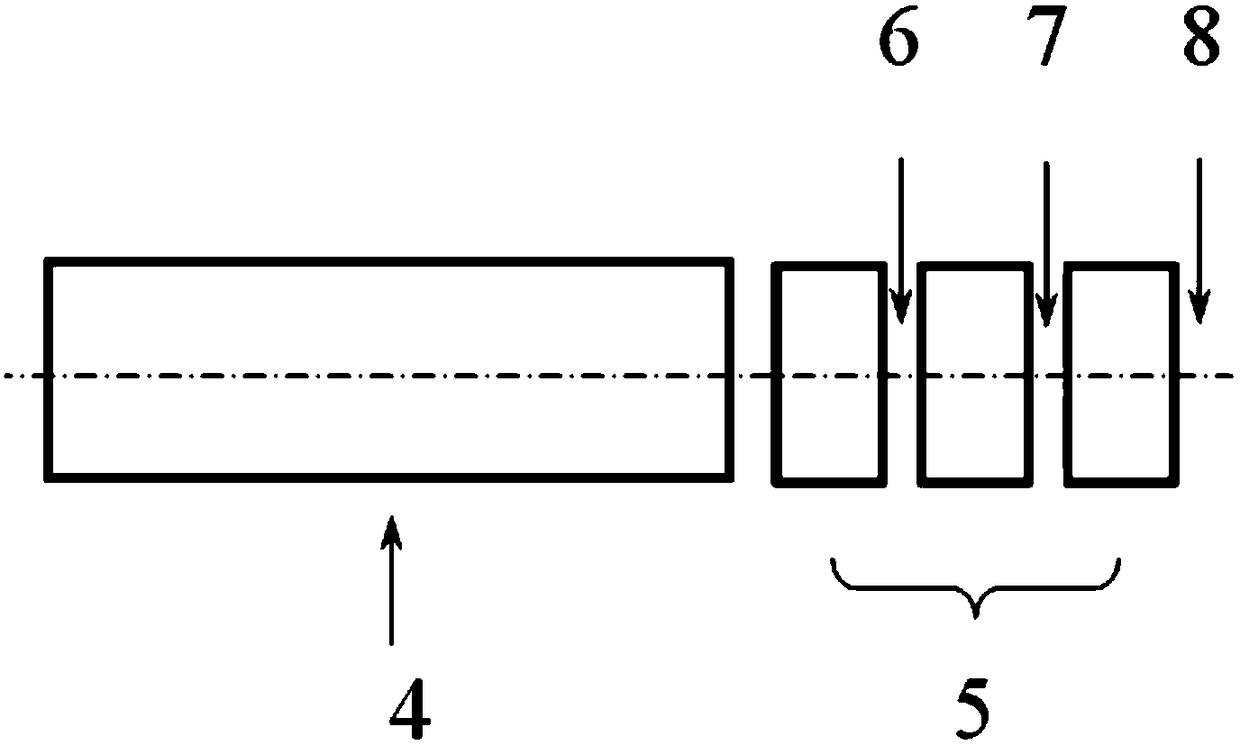

[0038] Among them, the spinneret (such as image 3As shown) the inner diameter of the hollow metal needles is 0.1mm, the distance between the centers of adjacent hollow met...

Embodiment 2

[0040] Such as figure 1 As shown, a filter based on a polymer multi-core fiber tube is wrapped with a polyethylene multi-core fiber tube by cigarette paper to form a cylindrical rod with a length of 4 mm. The diameter of the polyethylene multi-core fiber tube is 7.8mm, the inner diameter of the hole is 0.2mm, and the volume of the hole accounts for 76% of the volume of the multi-core fiber tube.

[0041] The preparation steps of polyethylene multi-core fiber tube are:

[0042] (1) Put polyethylene into the screw extruder, and continuously melt and extrude the thermoplastic resin through the spinneret at 120°C;

[0043] (2) The primary multi-core fiber tubes obtained above were gradually cooled, stretched 15 times, heat-set at 70° C. and cut to obtain polyethylene multi-core fiber tubes.

[0044] Among them, the spinneret (such as image 3 As shown) the inner diameter of the hollow metal needles is 0.2mm, the distance between the centers of adjacent hollow metal needles is 0...

Embodiment 3

[0046] Such as figure 1 As shown, a filter based on a polymer multi-core fiber tube is wrapped with a polylactic acid multi-core fiber tube by cigarette paper to form a cylindrical rod with a length of 6 mm. The diameter of the polylactic acid multi-core fiber tube is 7.7mm, the inner diameter of the hole is 0.3mm, and the volume of the hole accounts for 74% of the volume of the multi-core fiber tube.

[0047] The preparation steps of the polylactic acid multi-core fiber tube are:

[0048] (1) Put the polylactic acid into the screw extruder, and continuously melt and extrude the thermoplastic resin through the spinneret at 160°C;

[0049] (2) The primary multi-core fiber tubes obtained above were gradually cooled, stretched 10 times, heat-set at 90° C. and cut to obtain polylactic acid multi-core fiber tubes.

[0050] Among them, the spinneret (such as image 3 As shown) the inner diameter of the hollow metal needles is 0.3mm, the distance between the centers of adjacent ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com