Manufacturing method and using method of front tooth occlussion blocker based on 3D printing

A technology of 3D printing and manufacturing method, which is applied in the direction of articulator, dentistry, instruments, etc., can solve the problems of complicated operation, difficult to master, and the condyle is separated from the center relationship, and achieves the effect of simple operation, material saving and easy mastery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0033] Specific embodiment 1 is a method for manufacturing an anterior occlusal blocker based on 3D printing, the method comprising the following steps:

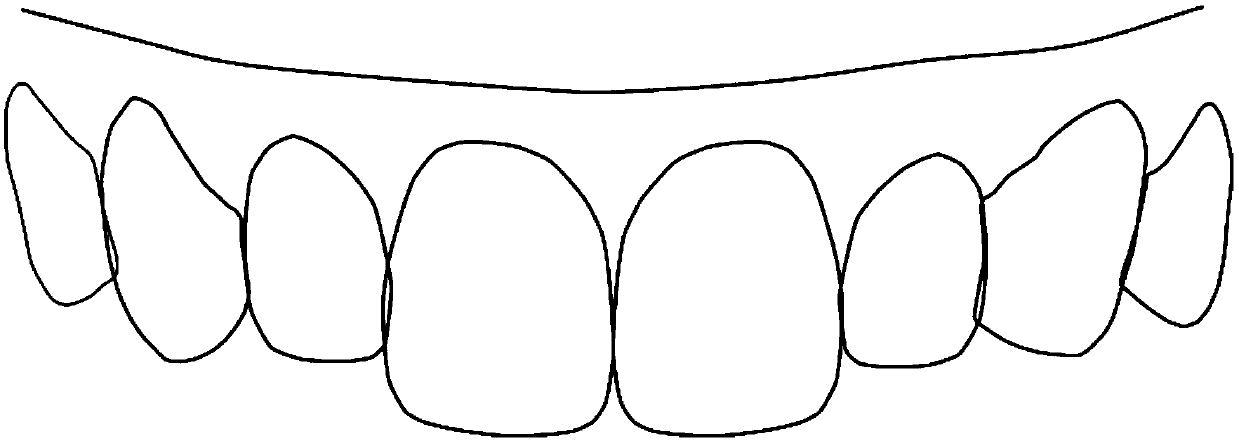

[0034] (1) Obtain a digital model: obtain a digital model of the patient's oral cavity by directly scanning the patient's maxillary dentition with an intraoral scanner, or scanning the patient's maxillary model / impression with a model scanner, such as figure 1 Shown is the schematic diagram of the acquired digital model of the oral cavity.

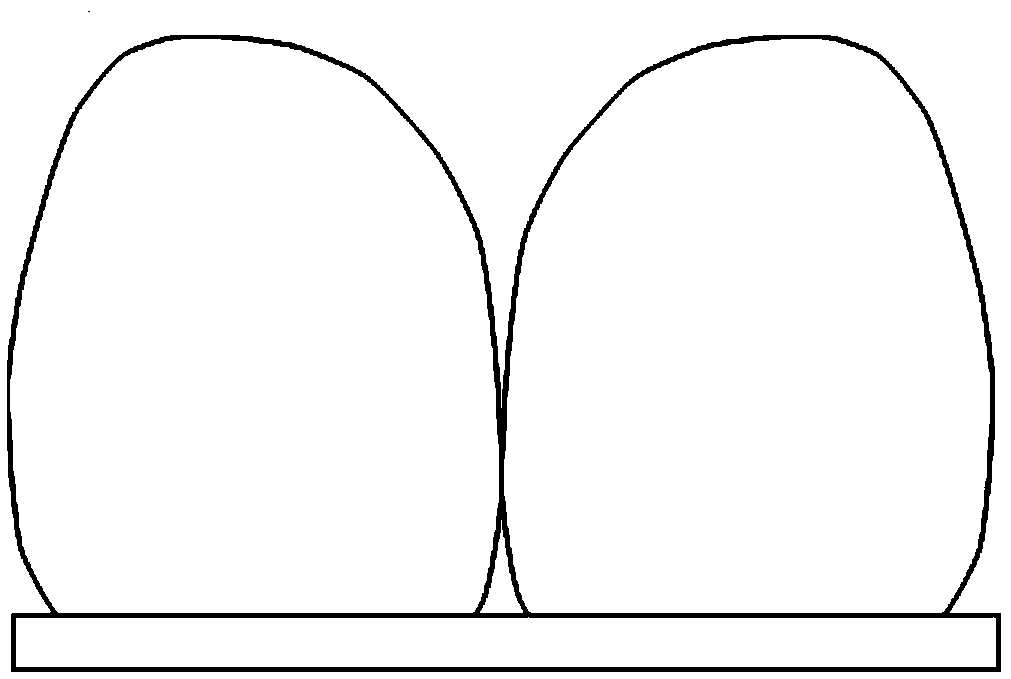

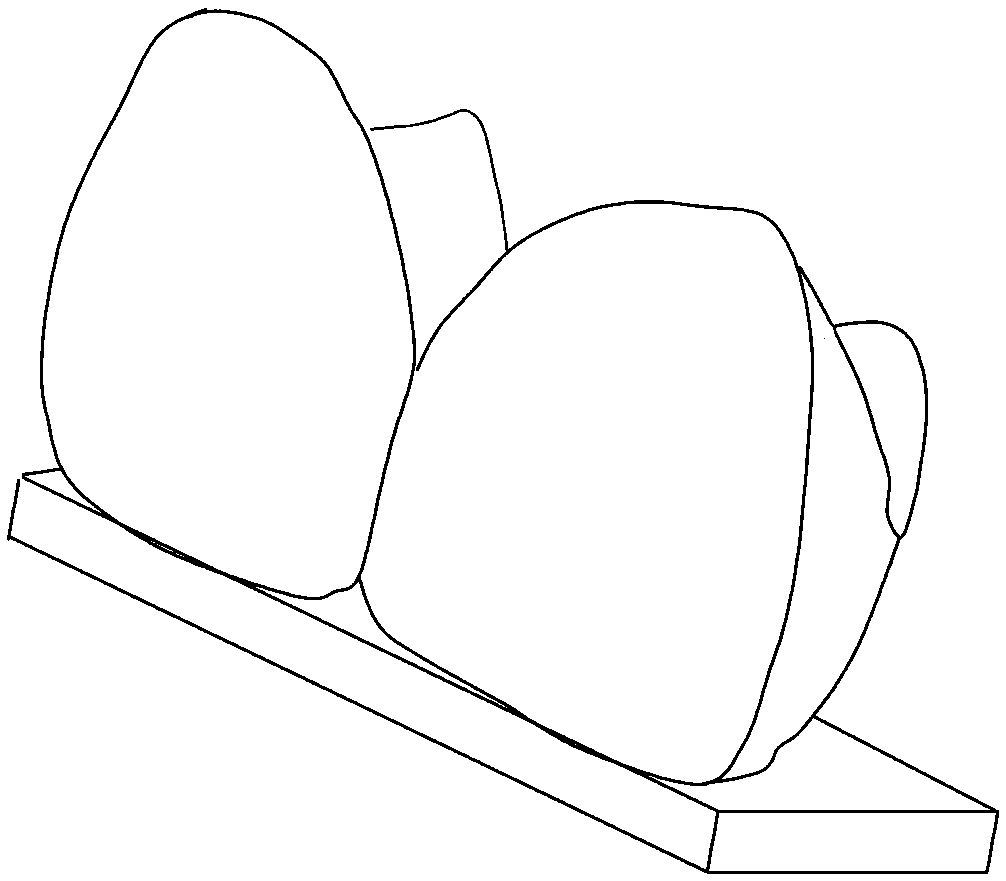

[0035] (2) Construct the occlusal guide plate, and build a 20*10*2mm flat plate in the three-dimensional modeling software to construct the occlusal guide plate.

[0036] (3) Position the occlusal guide plate, import the digital model of the oral cavity and the occlusal guide plate into the reverse engineering software at the same time, and move the occlusal guide plate to contact with the maxillary central incisors of the oral digital model through the object movement operation, and adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com