Die combination structure

A mold combination and mold technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of crushing of die-cutting products, inability to clear the debris in the knife cavity, and low precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

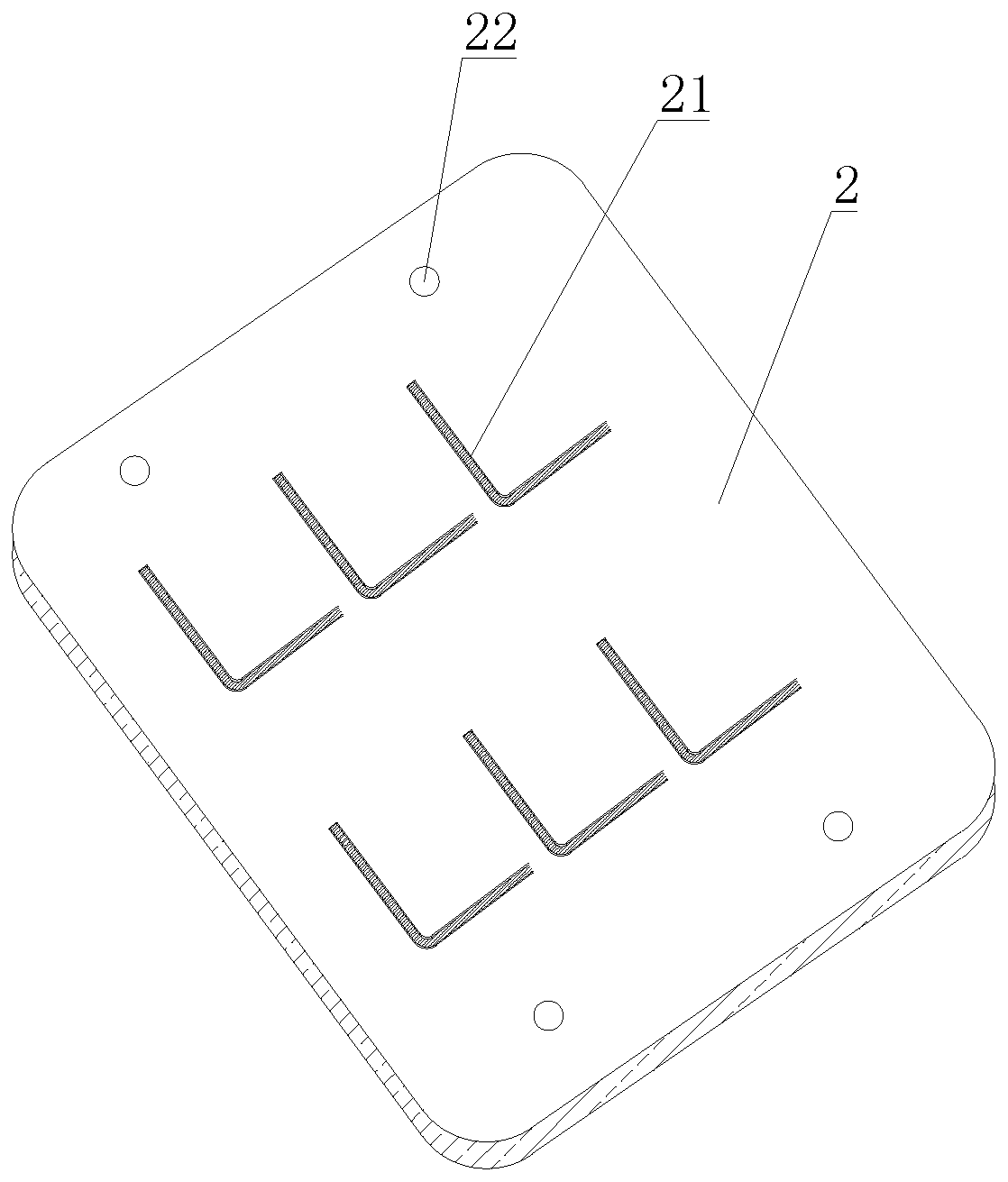

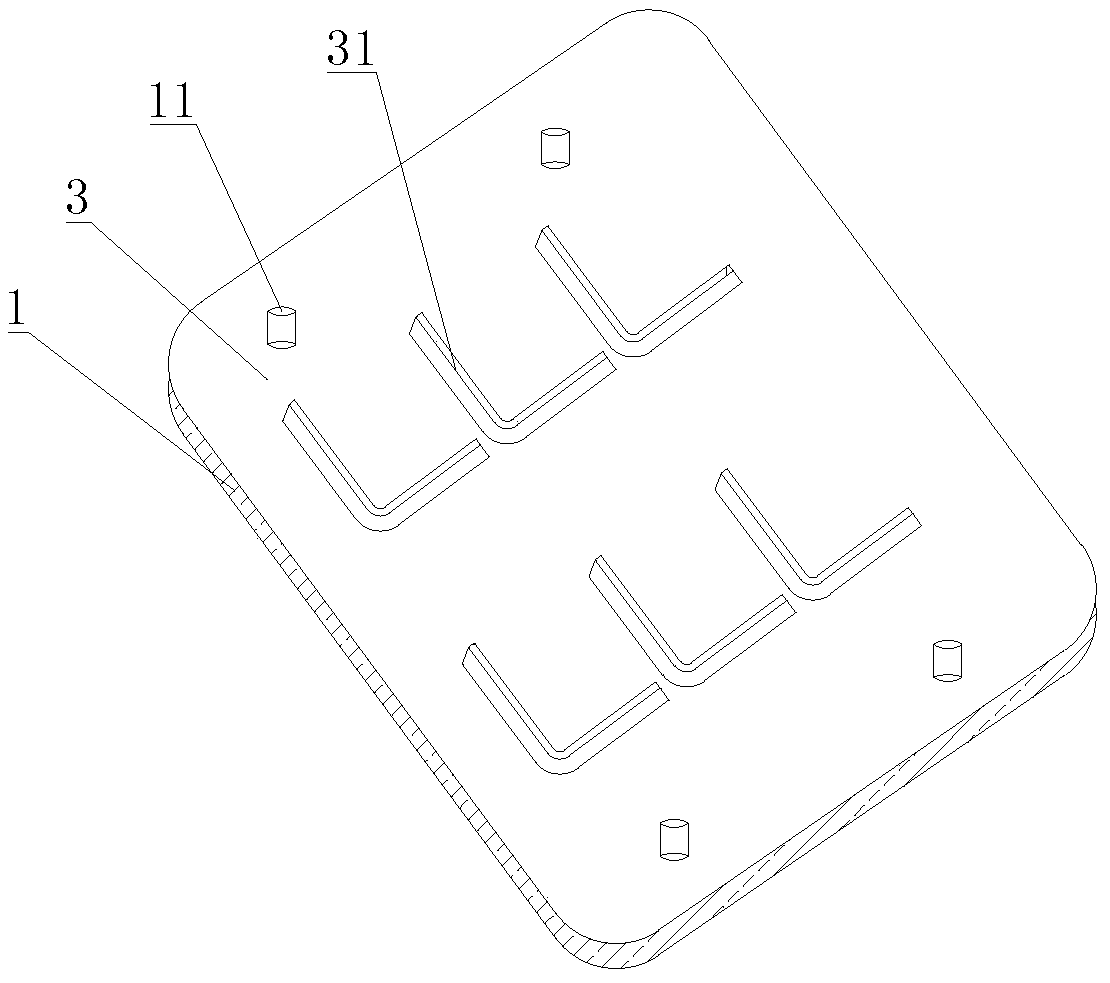

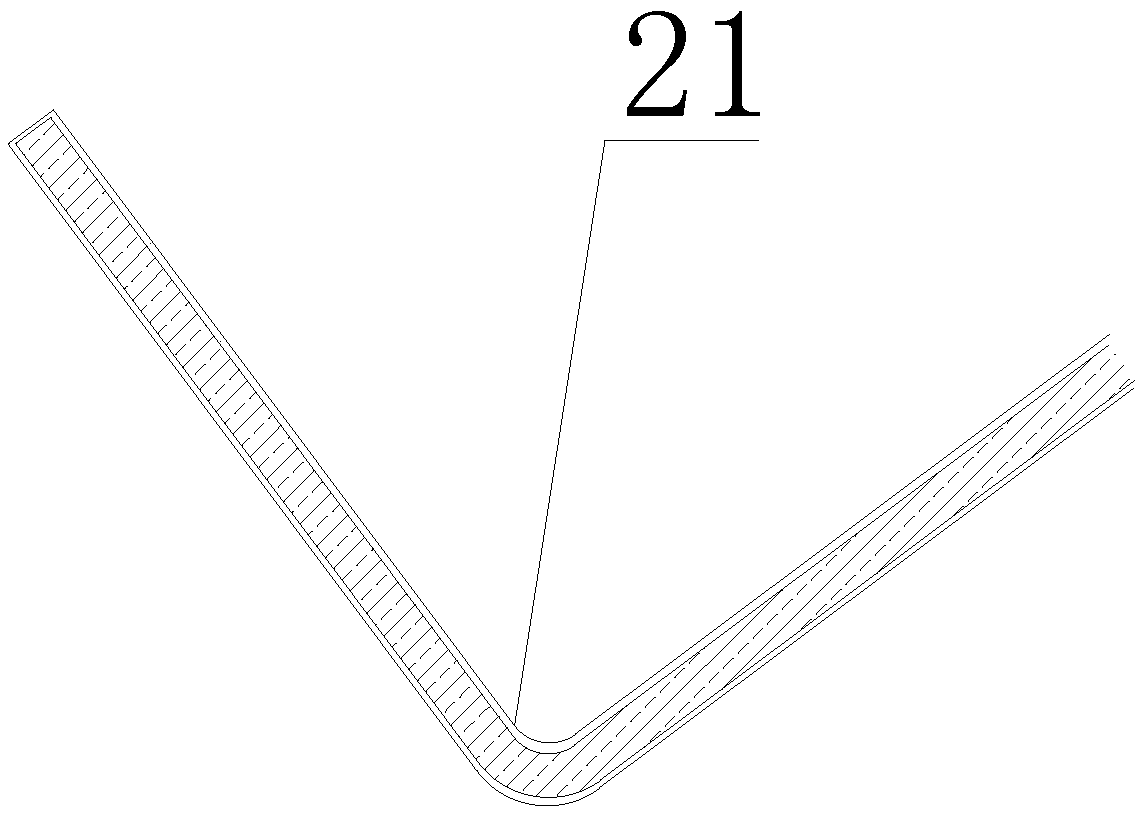

[0020] See figure 2 Shown, a kind of mold assembly structure, it comprises cutting die mold, and cutting die mold comprises upper cutting die mold (not drawn in the figure) and lower cutting die mold 1, and cutting die mold is installed on the die-cutting machine (not drawing in the figure) out), a milling cutter (not shown in the figure) is installed on the die-cutting machine, and the milling cutter is set correspondingly to the cutting die. 1 matches the shape of the die-cut product 31, which also includes a slow wire cutting mold 2, such as figure 1 , image 3 As shown, the slow wire cutting mold 2 is provided with several evenly arranged slow wire slotted holes 21 corresponding to the outline of the die-cut product 31, and the shape of the die-cut product 31 in this embodiment is an L with arc-shaped corners. shape, so the shape of the slow wire threading slot hole 21 is set to L shape, the corner of the L-shaped slow thread threading slot hole 21 is arc-shaped, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Arc angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap