Automobile part machining device

A technology for auto parts and processing devices, applied in the field of auto parts processing, can solve problems such as affecting processing efficiency, and achieve the effects of long service life, increased contact area, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following is further described in detail through specific implementation methods:

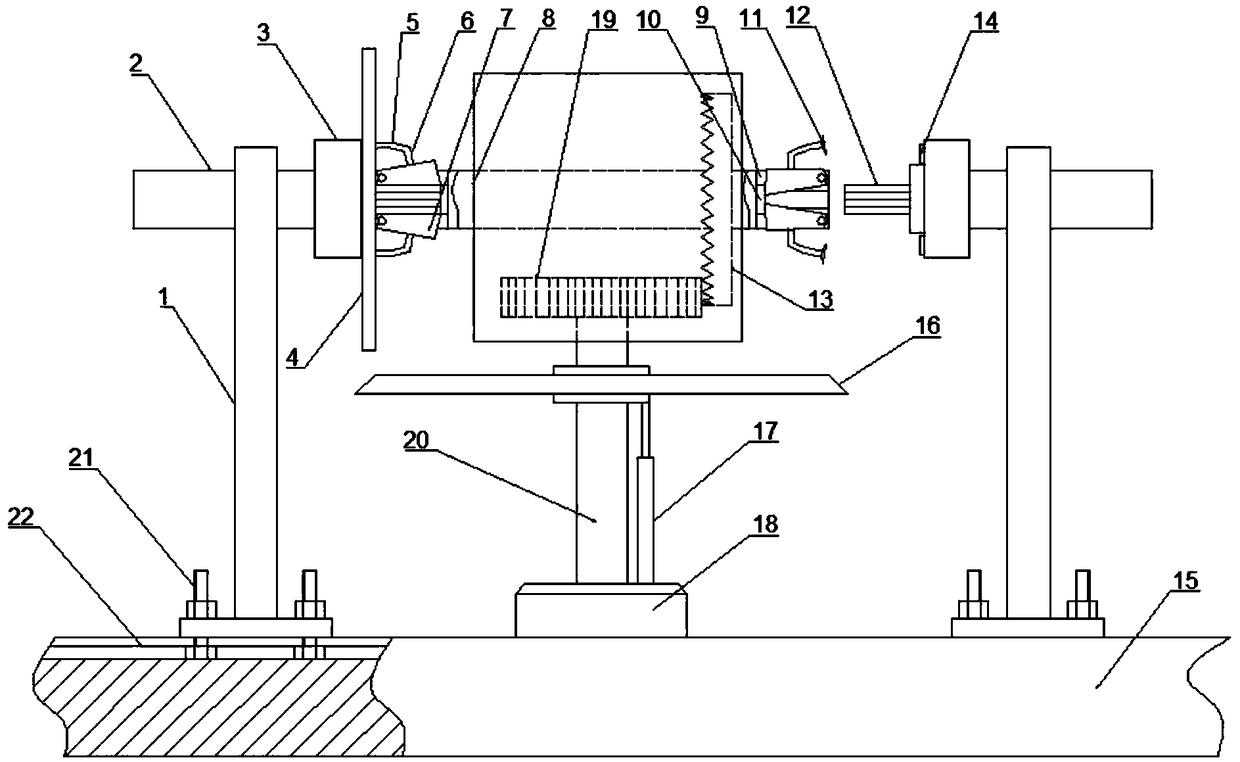

[0014] The reference signs in the drawings of the specification include: bracket 1, support shaft 2, positioning platform 3, brake pad 4, positioning claw 5, connecting rod 6, wedge 7, spacer shaft 8, keyway 9, positioning groove 10, suction cup 11 , spline table 12, gear plate 13, rubber ring 14, base 15, grinding wheel 16, hydraulic telescopic rod 17, motor 18, gear 19, rotating shaft 20, positioning bolt 21, T-shaped groove 22.

[0015] The embodiment is basically as attached figure 1 As shown: the auto parts processing device, including a base 15, the middle part of the base 15 is provided with a mounting groove, and a motor 18 with the output end facing upward is installed in the mounting groove through bolts, and the rotating shaft 20 of the motor 18 is crimped sequentially through bolts from bottom to top Grinding wheel 16 is arranged and connecting seat is installed by beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com