Crushing material hot-pressing forming line

A technology of hot pressing and crushing materials, which is applied in the field of machinery, can solve the problems of high impurities, low production efficiency, and low utilization rate, and achieve the effects of saving energy consumption, convenient operation and maintenance, and improving steelmaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described below in conjunction with the accompanying drawings.

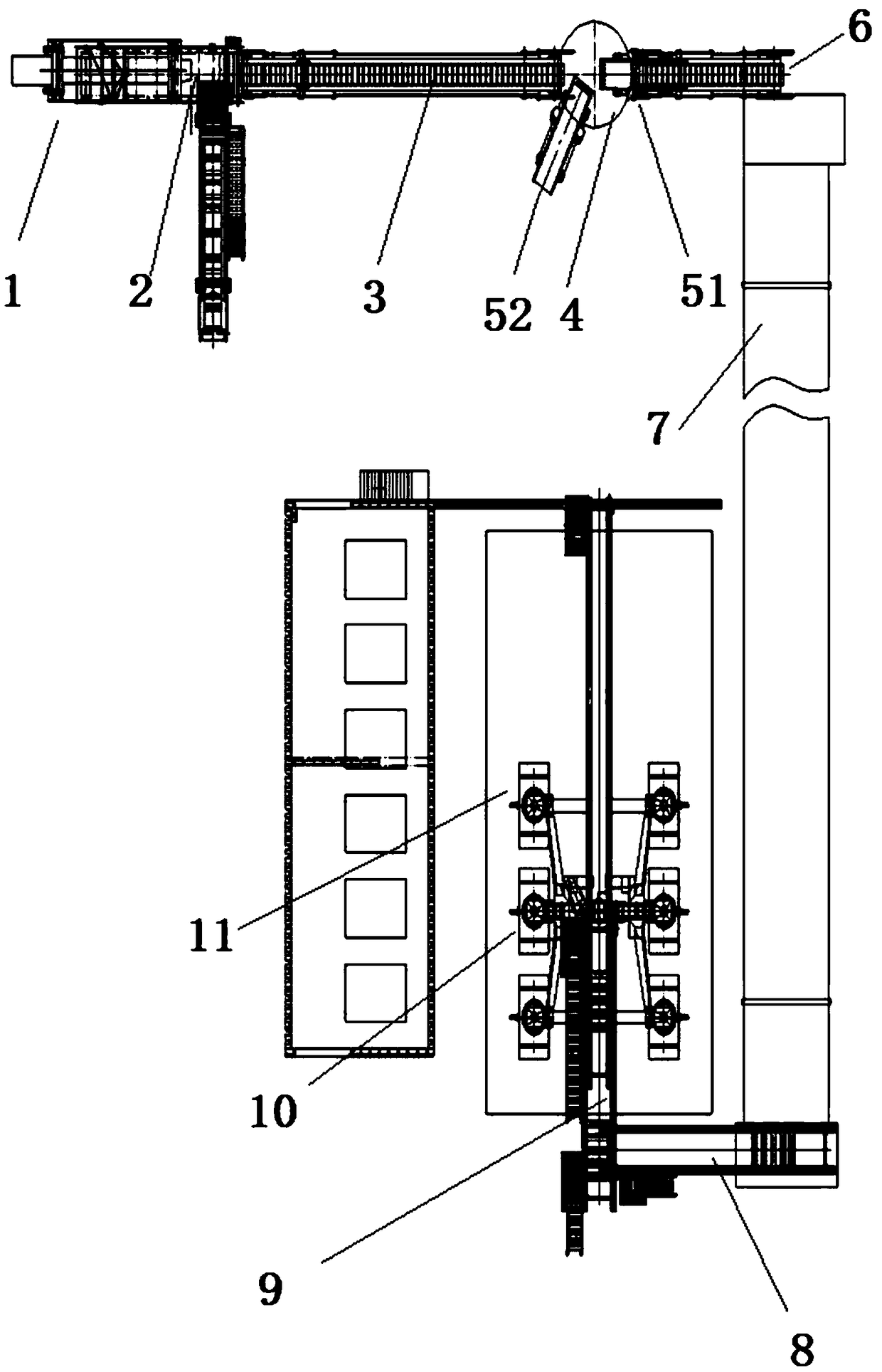

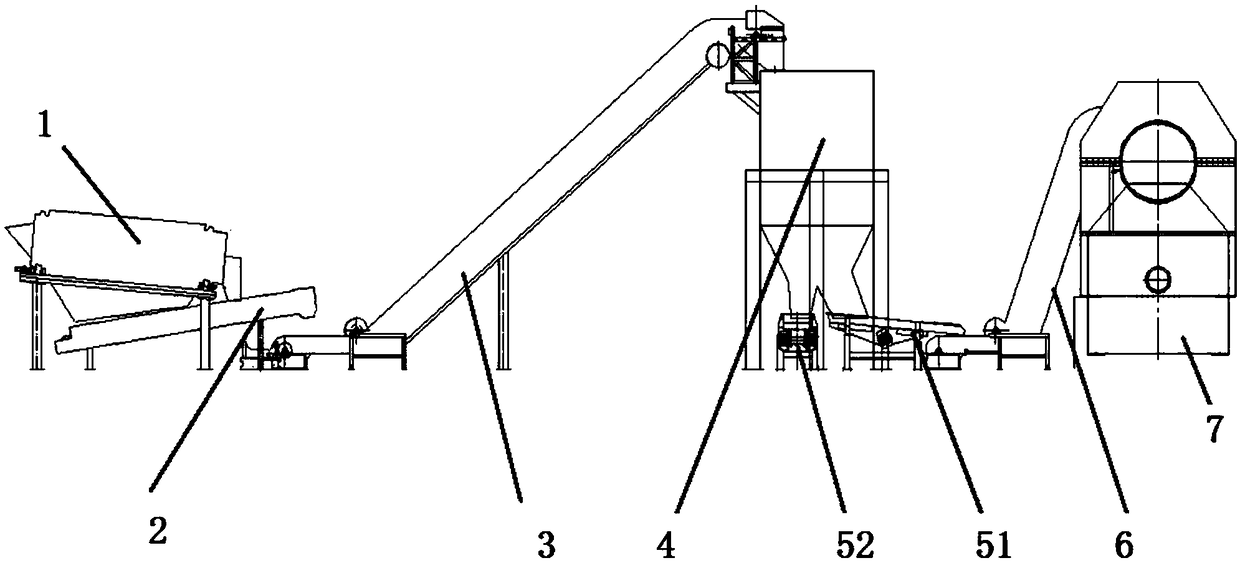

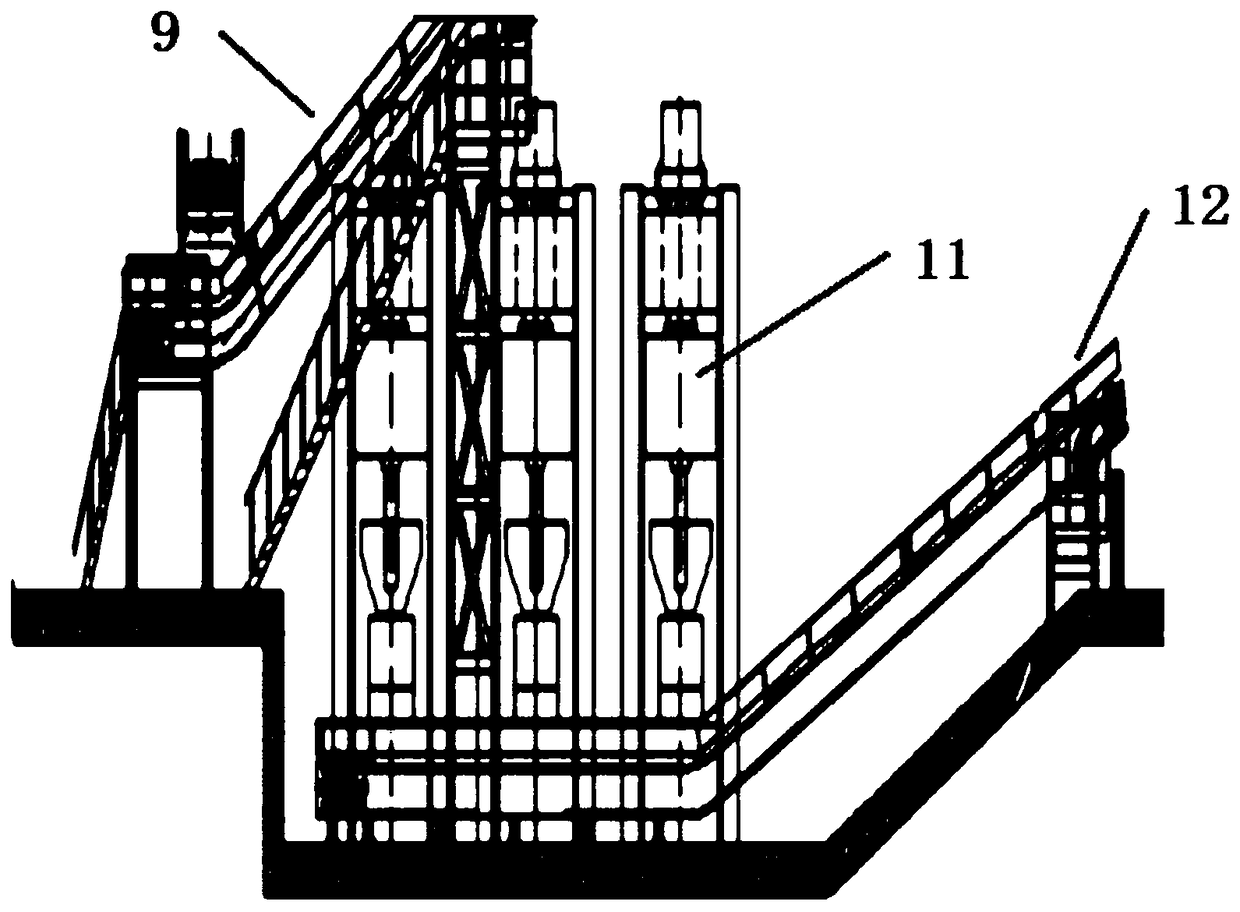

[0071] see Figure 1 to Figure 10 , a crushed material hot press molding line, including a cylindrical screen 1, a storage bin 4, a vibrating feeder, a rotary kiln 7, a material distribution mechanism 10, and at least two hot press molding machines 11; the material is moved along the transport direction Successively pass through cylindrical screen 1, storage bin 4, vibrating feeder, rotary kiln 7, material distribution mechanism 10, at least two hot press molding machines 11; cylindrical screen 1, storage bin 4, vibrating feeder and The rotary kiln 7 is arranged sequentially from left to right, and the discharge port of the rotary kiln 7 is located in front of the feed port of the rotary kiln 7; Port; the material distribution mechanism 10 is arranged on the left side of the rotary kiln 7; the material distribution mechanism 10 includes a discharge port that matches t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com