Separated paper tube airing device for emulsion explosive packaging paper tubes

A technology of emulsified explosives and wrapping paper, which is applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of affecting the bundling efficiency, large paper tube production capacity, and large quantity, so as to improve the overall bundling efficiency, improve efficiency and Yield rate and effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

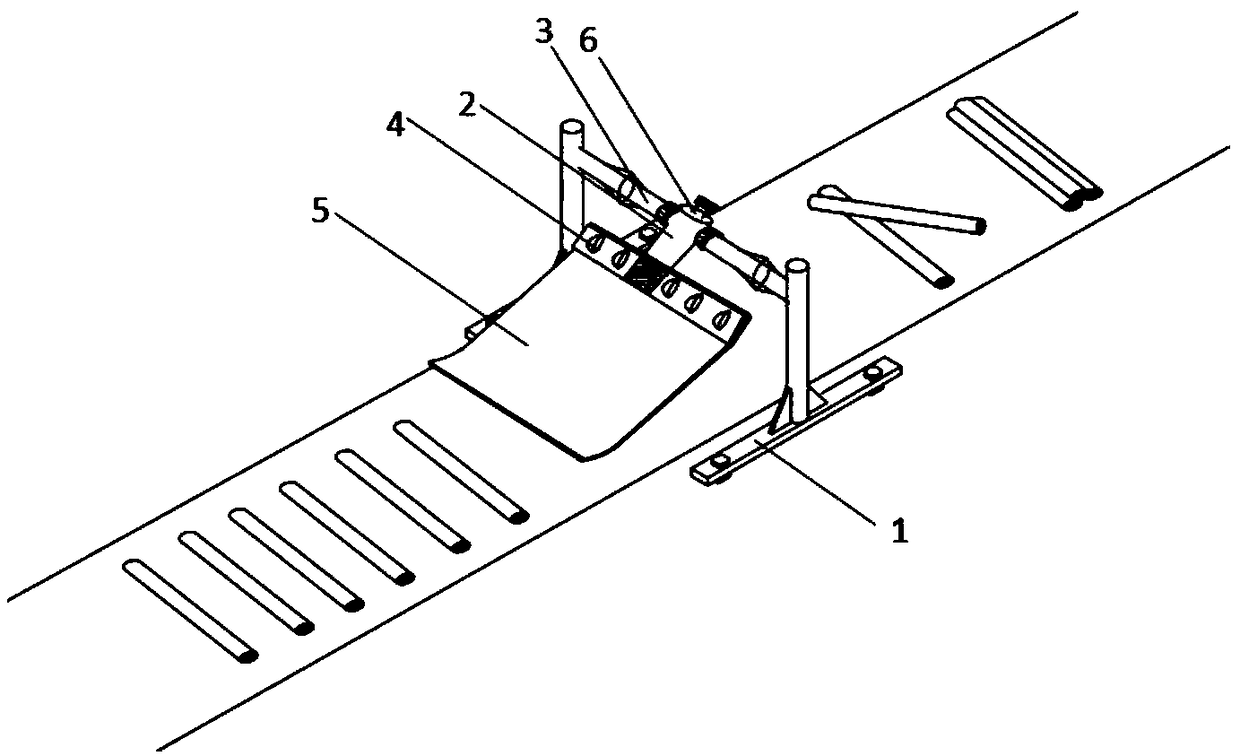

[0013] Such as figure 1 As shown, a device for separating and drying emulsion explosive packaging paper tubes, the device includes a fixed base 1, the fixed base is composed of two parallel supports, and a support rod 3 is horizontally arranged between the two supports, and the support rod It is a retractable telescopic rod, and the two supports are connected by a support rod. A rotating main shaft 2 is arranged in the middle of the supporting rod. One end of the rotating main shaft is rotatably connected to the supporting rod. There is a brush 5 inside, and the brush is inserted in the card slot. The brush is a rubber brush made of rubber, which can be detachably connected to the card slot. device6.

[0014] Adjust the width of the device by stretching the telescopic rod to adapt to different widths of the conveying production line, and then adjust the angle of the rotating main shaft to adjust the position of the rubber brush, and then fix the rotating main shaft through th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap