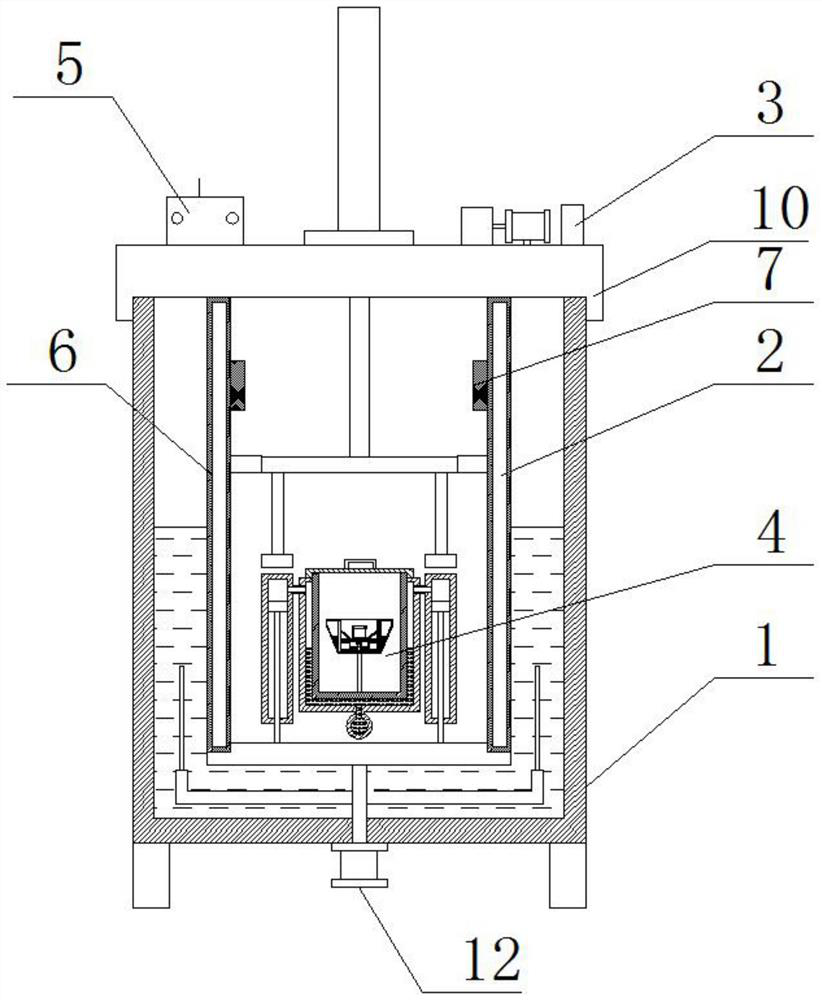

A device for thawing frozen egg cells

An egg cell and sleeve technology, applied in the field of egg cell thawing, can solve the problems of affecting the egg cell awakening level, lowering the egg cell level, and reducing the egg cell level, so as to avoid accidental frostbite.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

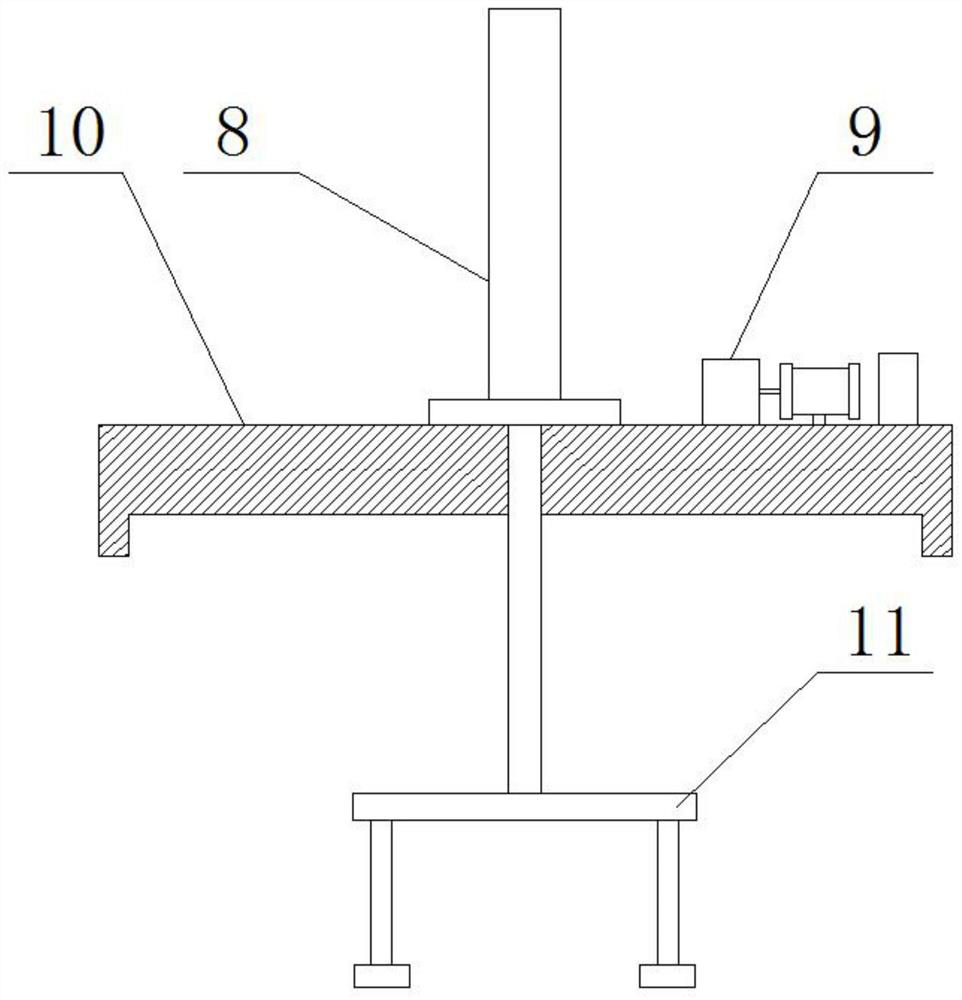

[0028] As a preferred embodiment of the present invention, both ends of the thrust rod set 11 are provided with compression rods, and the compression rods correspond to the sliding sleeves 22 .

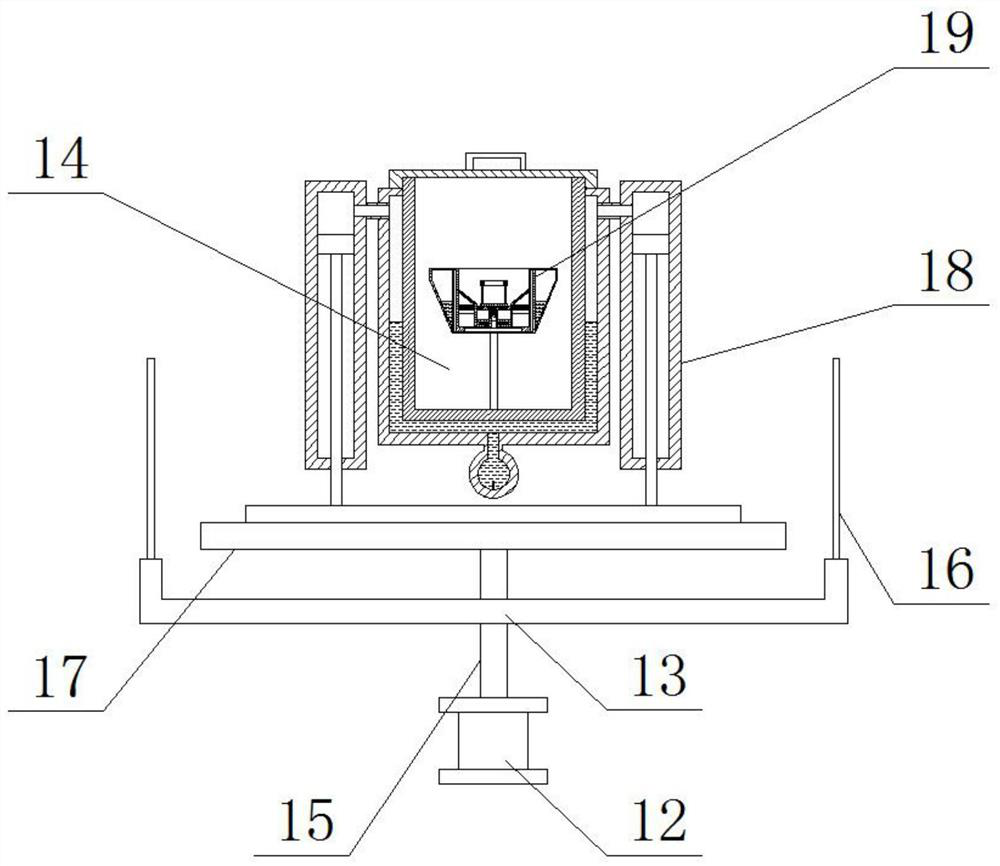

[0029]As a preferred embodiment of the present invention, an electromagnet is arranged inside the electromagnetic column 16 , and an electromagnetic coil is sheathed on the electromagnet.

[0030] As a preferred embodiment of the present invention, the electromagnetic board 37 is provided with winding wires.

[0031] As a preferred embodiment of the present invention, the cover 21 is arranged on the top of the fixing sleeve 20 .

[0032] As a preferred embodiment of the present invention, both ends of the flow passage 32 are connected with the antifreeze chamber 31 and the positioning chamber 35, and the bottom of the water supply chamber 33 is connected with the air passage 34 and the compression sleeve 36, the A water seepage plate 41 is arranged on the top of the water replenishme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com