A blade pitch angle compensation control method and a wind turbine anti-overspeed control method

A wind turbine, compensation control technology, applied in speed control, wind power generation, wind engine, etc., can solve problems such as generator speed exceeding, wind turbine overspeed shutdown, load reduction, smooth shutdown control, etc., to prevent overspeed and ensure stability Running, reducing the effect of limit load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

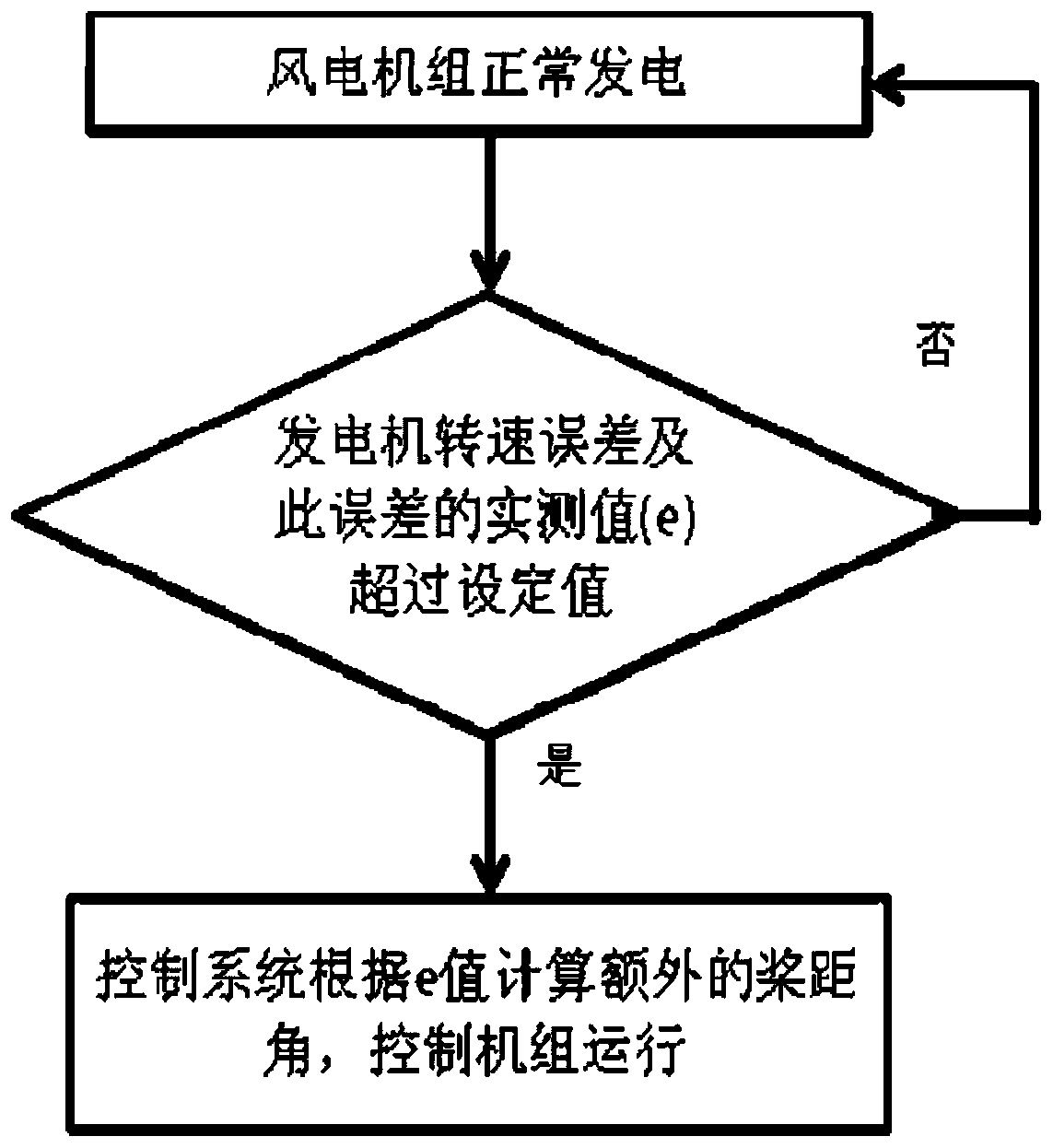

[0020] In view of the problem described in the background art, that is, when an extreme external environment occurs in a wind turbine, the existing pitch angle control method cannot satisfy the problem of load reduction and smooth control. This embodiment lists a new blade Pitch angle compensation control scheme. The specific technical scheme is as follows.

[0021] Reference attached figure 1 As shown, the wind turbine anti-overspeed control method of this embodiment is to add a blade pitch angle compensation control method on the basis of the existing wind turbine pitch system, and the method includes the following steps:

[0022] (1) According to a certain time period, such as 10-20ms, the generator speed of the wind turbine generator in the continuous time period is monitored in real time.

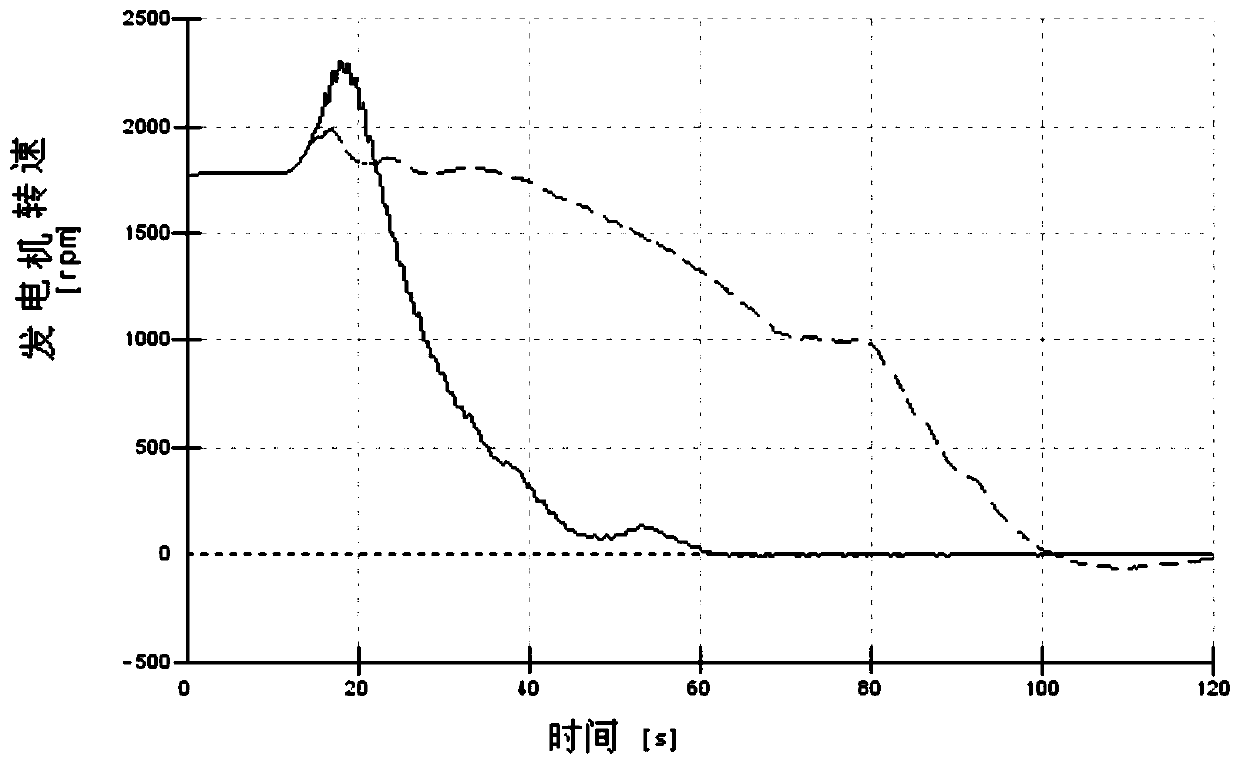

[0023] (2) Calculate the generator speed error of the n-1th cycle corresponding to the nth cycle and the rate of change of the speed error; the rate of change of the speed error is based on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com