TDLAS (Tunable Diode Laser Absorption Spectroscopy) measuring air chamber device simulating operating conditions of internal combustion engine

A technology for working conditions and internal combustion engines, which is applied in the field of measuring gas chamber devices and TDLAS measuring gas chamber devices simulating the working conditions of internal combustion engines, can solve the problems of inability to realize on-line measurement and poor test accuracy of TDLAS testing technology, and achieves compact and high-quality design. The effect of similarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

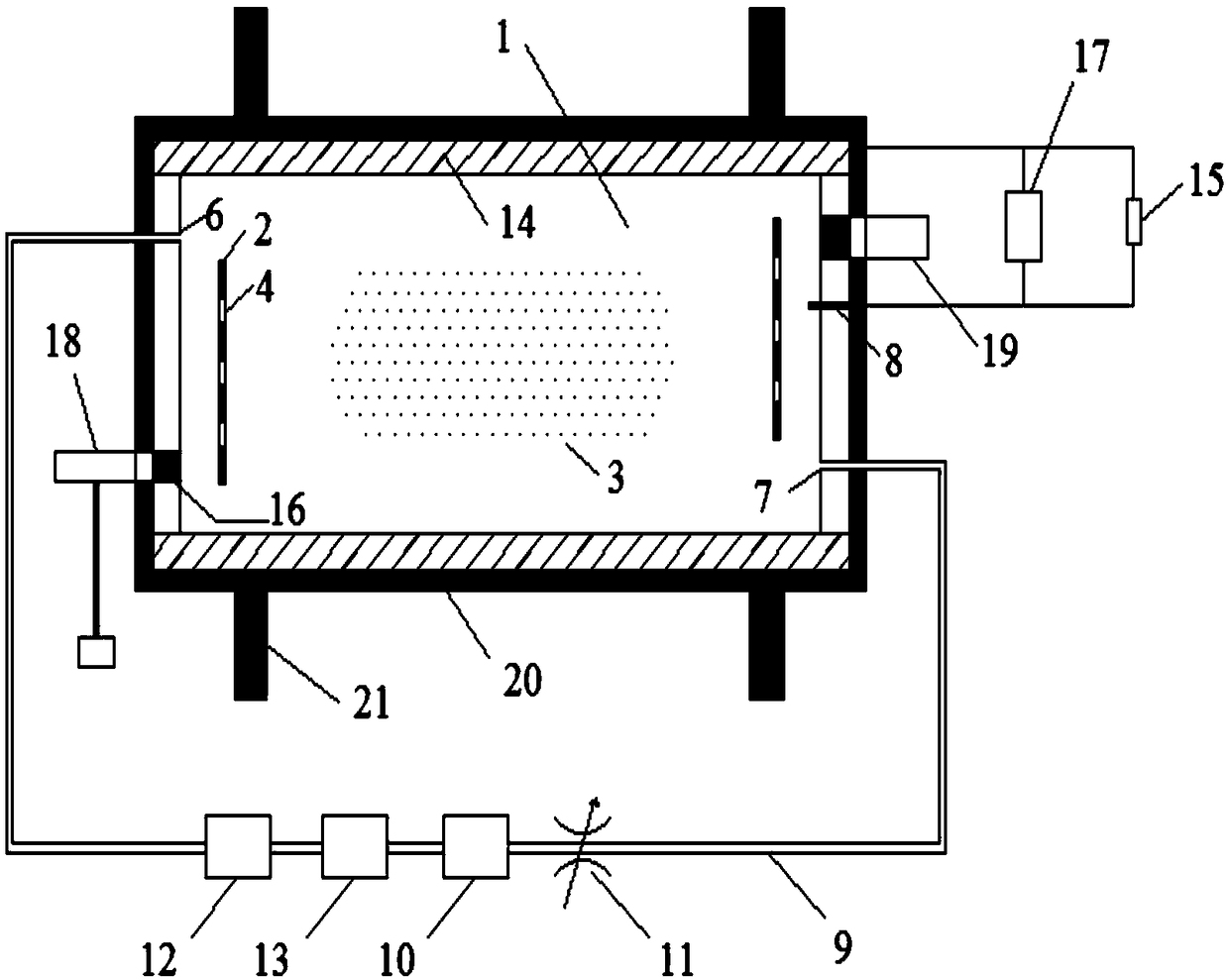

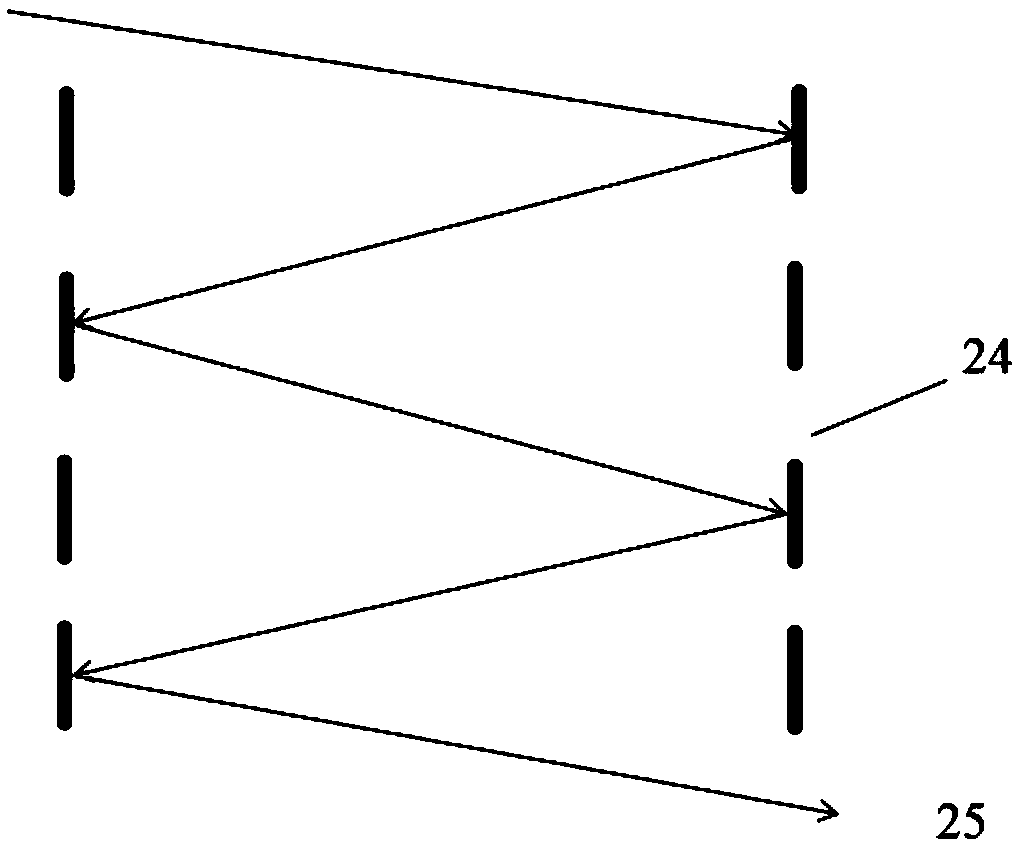

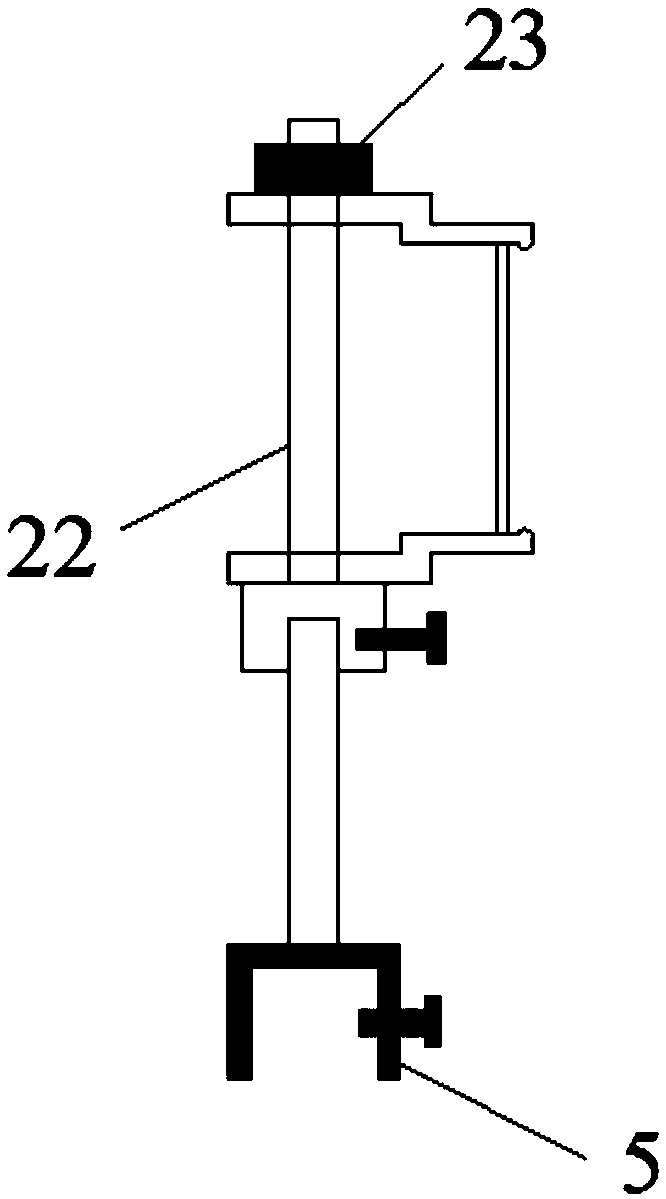

[0023] In the figure: 1 is the absorption air chamber, 2 is the mirror cavity, 3 is carbon nano-particles, 4 is the guide rail, 5 is the base, 6 is the air inlet hole, 7 is the air outlet hole, 8 is the sensitive probe of the TEC temperature controller, and 9 is the Circulation pipe, 10 is air pump, 11 is air valve, 1 is 2 agitator, 13 is pressure gauge, 14 is heating wire, 15 is power supply, 16 is visualization window, 17 is He:Ne laser collimator, 18 is can Tuned diode laser, 19 is a detector, 20 is a heat shield, 21 is a bracket, 22 is a knob, 23 is a nut, 24 is a medium optical path output port, and 25 is a long optical path output port.

[0024] Inside the gas chamber device is an absorption gas chamber, which is used to store target gases and particles, and an adjustable high-reflection optical cavity is placed inside to increa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com