Special fixture for puncture test of lithium battery diaphragm

A lithium battery diaphragm and special fixture technology, which is applied to the parts of electrical measuring instruments, measuring devices, and measuring electrical variables, etc., can solve the problems of easy sliding of the diaphragm, inaccurate test data, instability, etc., and reduce misoperation Reproducibility and repeatability, and the effect of reducing operational instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

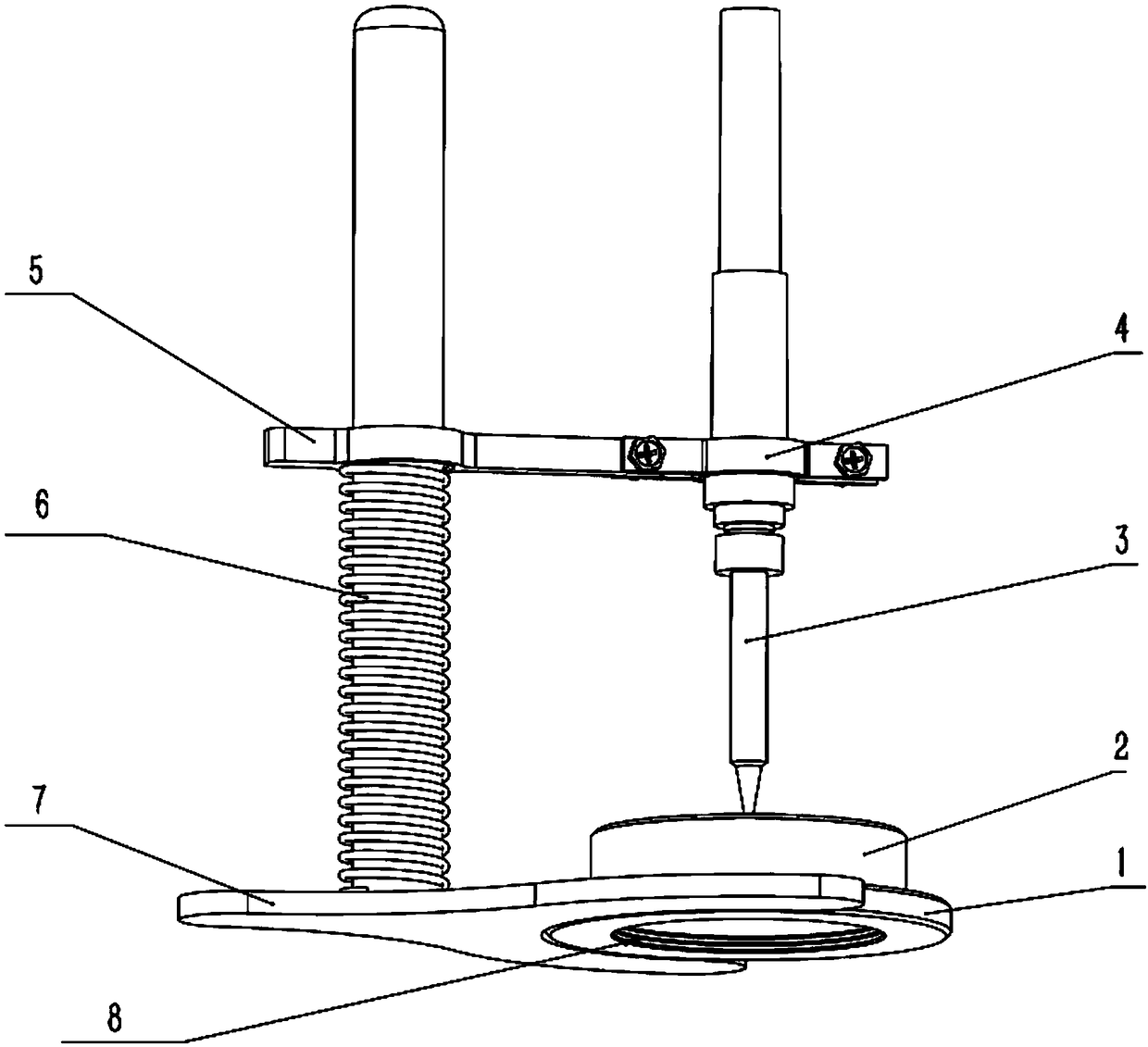

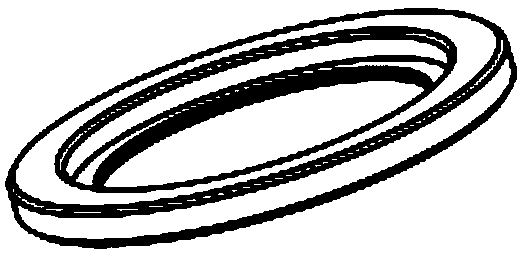

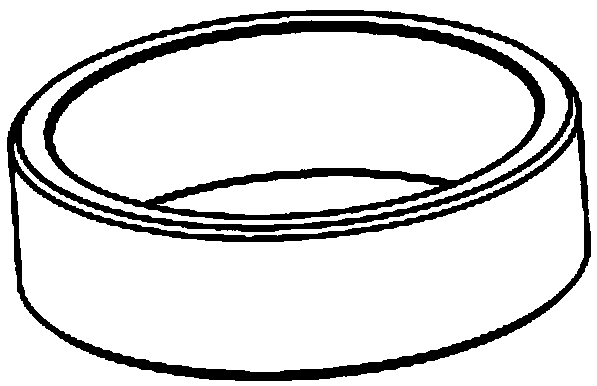

[0016] Such as figure 1 As shown, a special fixture for the point rupture test of the lithium battery diaphragm according to the present invention includes a B-type soldering iron tip 3 and a lower base 1 . Such as figure 1 , Figure 2a-Figure 2e As shown, an upper pressure ring 2 is arranged above the lower base 1, and the B-type soldering iron tip 3 is arranged above the upper pressure ring 2 through a fixed structure; a cage 7 is clamped on the outer side of the lower base 1, and the holder A compression spring 6 is connected between the fixing structures of the frame 7, and a rubber gasket 8 is pasted on the bottom surface of the upper pressure ring 2.

[0017] Further, the fixing structure includes a fixing clip 4 and a fixing arm 5, the fixing arm 5 and the fixing clip 4 are connected by bolts, and the fixing clip 4 clamps the B-type soldering iron tip 3 by screwing on the bolts.

[0018] Furthermore, a guide post is fixed on the cage 7, the compression spring 6 is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com