Data high-speed collection method based on industrial internet platform

An industrial Internet and high-speed acquisition technology, applied in the direction of electrical components, transmission systems, etc., can solve the problems of high acquisition rate, low acquisition rate, no transmission, etc., to increase acquisition rate, increase communication rate, improve reliability and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described, and in the present invention, take collecting thickness difference measurement signal as example:

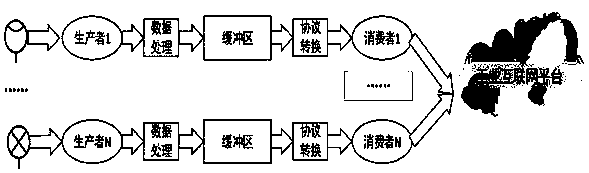

[0019] figure 1 It is a flow chart of the high-speed data collection method based on the industrial Internet platform, and the process is as follows:

[0020] (1) Obtain the thickness difference measurement signal: receive the thickness difference measurement signal from the thickness controller or thickness gauge, and multiple devices can generate multiple different thickness difference signals;

[0021] (2) The producer performs signal processing on the obtained thickness difference measurement signal and sends it to the buffer: according to different equipment conditions, there are different producers, ranging from 1 to N, and N represents the number of producers, one by one with the number of equipment correspond. After the producer gets the data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com