Soybean planting device

A planting device and soybean technology, applied in the directions of sowing, hole-seeding planters, manual sowing tools, etc., can solve problems such as unfavorable germination, low soil and air circulation, and achieve outstanding effects, avoid artificial covering, and ensure the effect of seedling emergence environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

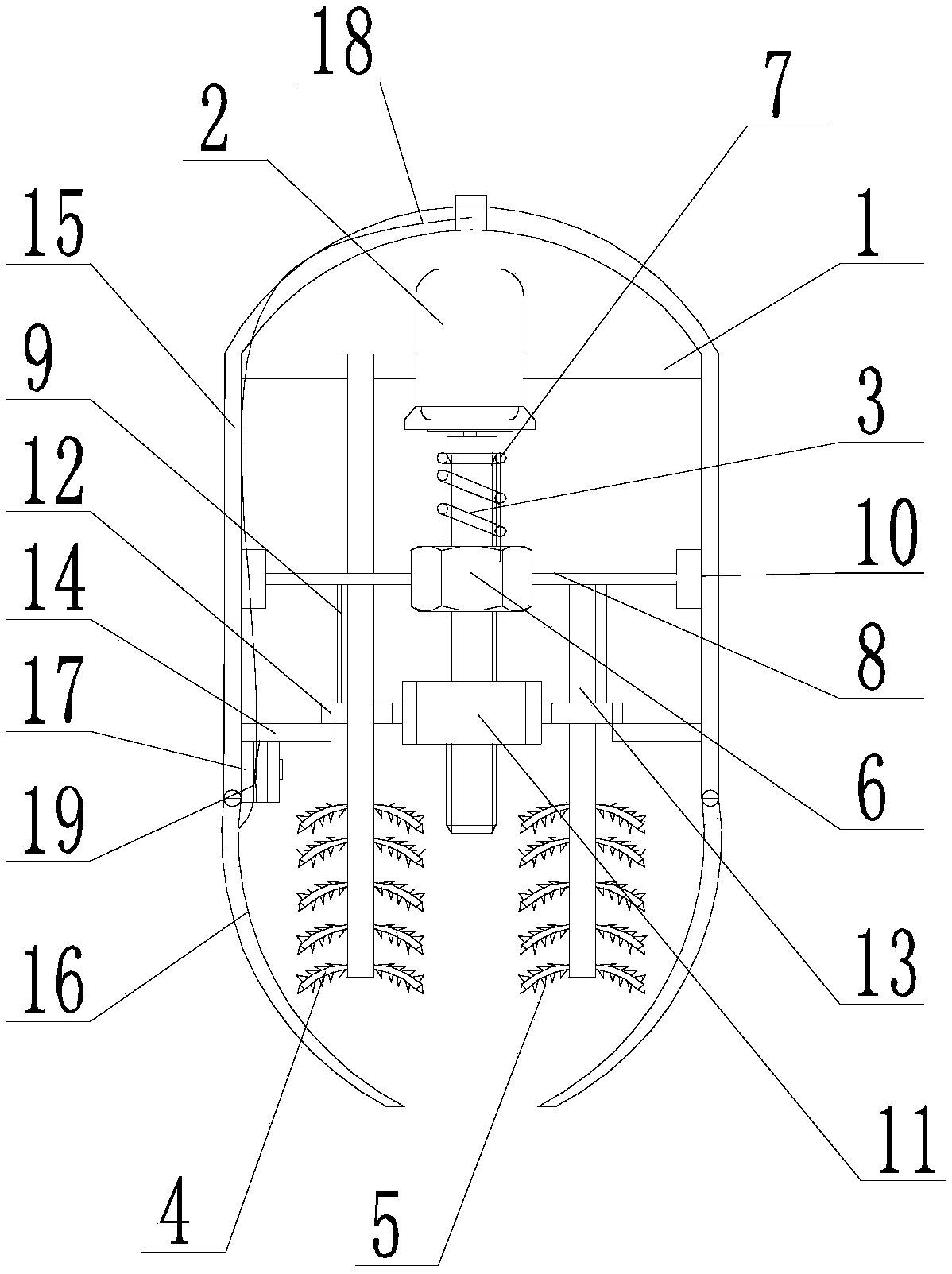

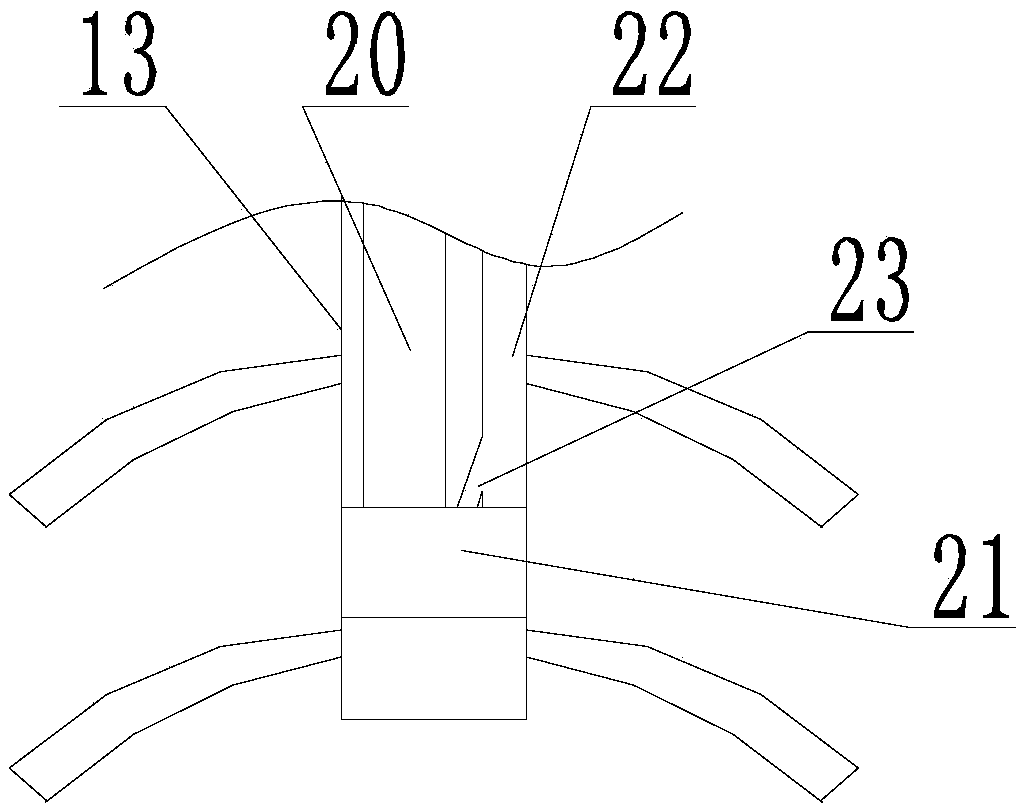

[0025] Such as figure 1 , 2 As shown, the soybean planting device includes a sowing part, a soil loosening part, a soil gathering part and a frame 1, and the sowing part, the soil loosening part and the soil gathering part are installed on the frame 1; the soil loosening part includes a motor 2 and a threaded output shaft 3 , blade 4, moving nut 6, return spring 7, pole 8, linkage rod 9, slider 10, gear 11, spline teeth 12, spline shaft 13 and stopper 14, spline shaft 13 and frame 1 Rotational connection, the motor 2 drives the threaded output shaft 3, the threaded output shaft 3 is sequentially connected to the moving nut 6 and the gear 11 in the longitudinal direction, the moving nut 6 is fixed to the support rod 8, the support rod 8 is connected to the slider 10, and the slider 10 and the bracket are slidably matched , the gear 11 meshes with the spline teeth 12, the spline teeth 12 are sleeved with the spline shaft 13, and the bottom of the meshing part of the spline teet...

Embodiment 2

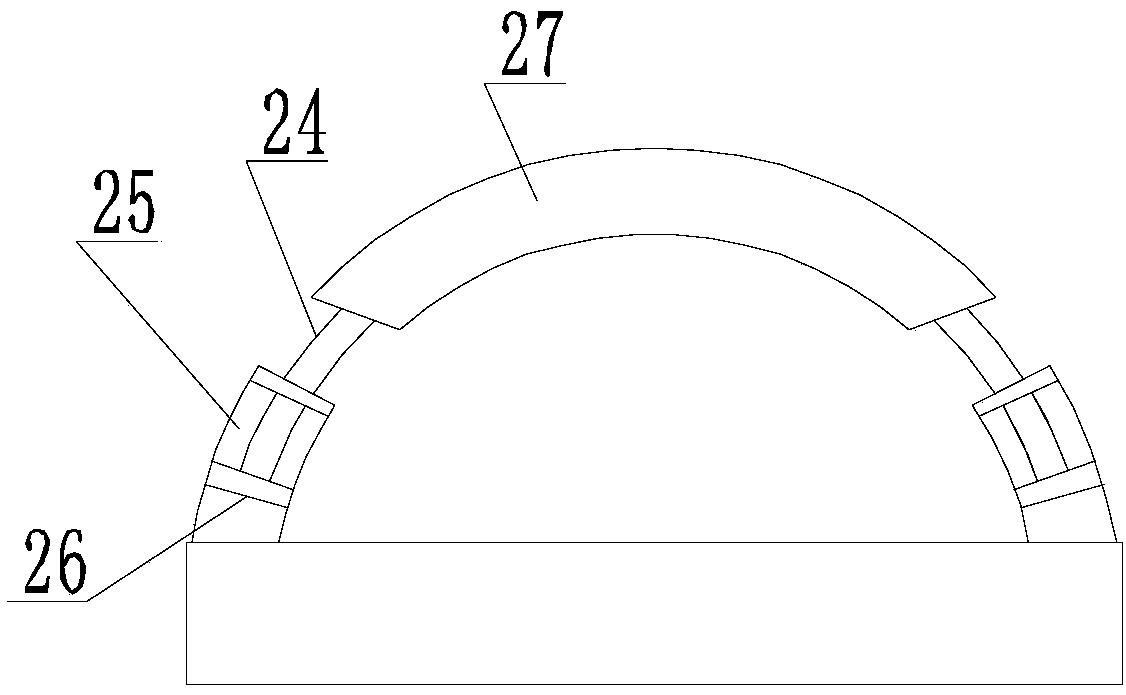

[0028] Such as figure 1 , 2 , 3 and 4, the difference from the above embodiment is that the handle 27 includes an arc-shaped telescopic rod 24, an arc-shaped sleeve 25 and a limit block 26, and the arc-shaped sleeve 25 is fixedly connected to the frame 1, and its inner sleeve An arc telescopic rod 24 is established, and the bottom end of the arc telescopic rod 24 is affixed to a stop block 26 , the long diameter of the stop block 26 is greater than the diameter of the arc sleeve 25 , and the arc telescopic rod 24 is connected to the backguy 18 . When lifting the handle 27 like this, the arc telescopic rod 24 moves up, and the stay wire 18 can be tightened, and the gathering of the soil can be realized quickly. At the same time, the stop block 26 is used to limit the arc telescopic rod 24 from sliding out of the arc sleeve 25 . The outer side of the support plate 15 is provided with an arc-shaped restraint sleeve 28, and the side wall of the arc-shaped restraint sleeve 28 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com