A kind of preparation method of rose tea

A rose tea and rose technology, applied in the food field, can solve the problems of easy decomposition and oxidation of rose pigment, long scenting time, reduction of rose tea fragrance, color quality, etc.

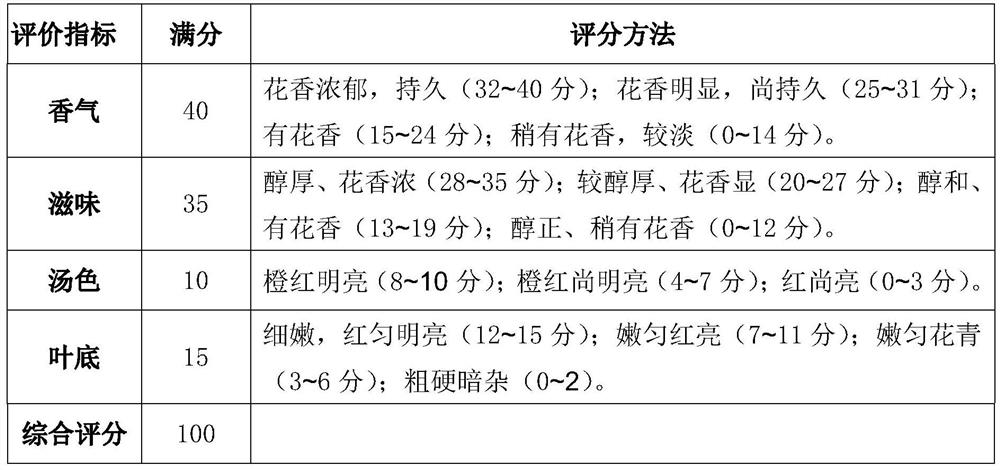

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention provides a kind of preparation method of rose tea, and preparation step comprises:

[0031] A. Fresh roses picked before 7 o'clock in the morning are screened by a sorting machine, and then manually selected to obtain roses; the roses and tea base are mixed at a mass ratio of 1:2 to 5, and the first rose is obtained after mixing. The mixture is scented for 5-8 hours; the first mixture after scenting is separated and cooled to room temperature to obtain the first treated rose and the first treated tea dhool; specifically, it is better to control the moisture content of the tea dhool at 4-6%. Rose scented tea is prepared by scenting, so that the tea base can absorb the fragrance of roses, integrating the tea flavor and flower fragrance, and at the same time can remove the astringency of the tea base and improve the quality of the tea; the scenting time of traditional high-quality scented tea can be as long as 10-12 hours. , the scenting time of the e...

Embodiment 1

[0047] Rose tea preparation steps are:

[0048] A. The fresh roses picked before 7 o'clock in the morning are screened and selected to obtain roses; the roses and tea dregs are mixed at a mass ratio of 1:2 to obtain the first mixture, with a stacking thickness of 30cm and a temperature of 30 ~45°C, scented for 5 hours; separate the first mixture after scenting, and cool down to room temperature to obtain the first processed rose and the first processed tea dhool;

[0049] B. Dried the first processed tea dhool to a moisture content of 4%, mixed with the first processed rose to obtain the second mixture, and the microwave power was 200W, and treated for 10 minutes; separated the microwave-treated second mixture to obtain the second processed rose and the second processed tea dhool;

[0050] C. drying the second processed tea dregs to a moisture content of 8%, to obtain scented tea leaves;

[0051] D. Mix the roses with the second treatment roses at a mass ratio of 8:1, lay th...

Embodiment 2

[0055] On the basis of the preparation steps in Example 1, change the scenting process parameters in step A, specifically, the mass ratio of rose to tea base is 1:5, the stacking thickness is 20 cm, and the scenting process takes 8 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com