Intensive precision printing and size mixing system

A technology of precise printing and pulp mixing system, applied in the field of textile production, can solve the problems of excess pulp, waste, and great influence of the amount of thickener, etc., and achieve clean and tidy operating environment, good color reproducibility, and accurate weighing unmistakable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

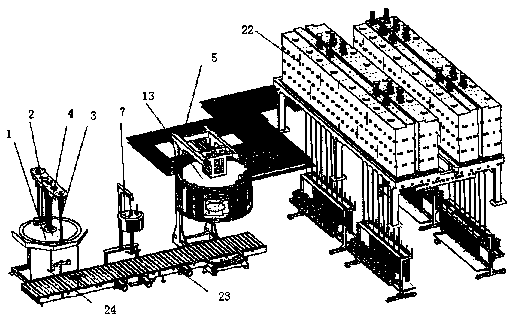

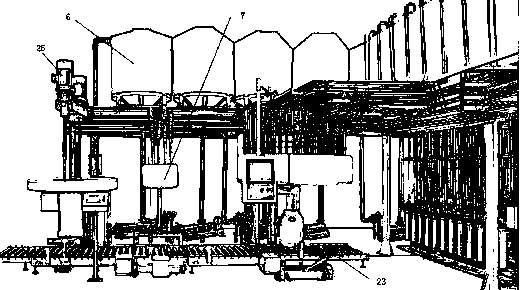

[0034] Embodiment 1: as attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a kind of intensive type precision printing paste mixing system provided by the invention comprises:

[0035] The first liquid injection device 1 includes a fixed platform 2; the fixed platform is equipped with a liquid injection pipe 3 and a first stirring shaft 4; the liquid injection pipe is used for externally connecting the liquid storage tank 6; The direction of the central axis passes through the fixed platform;

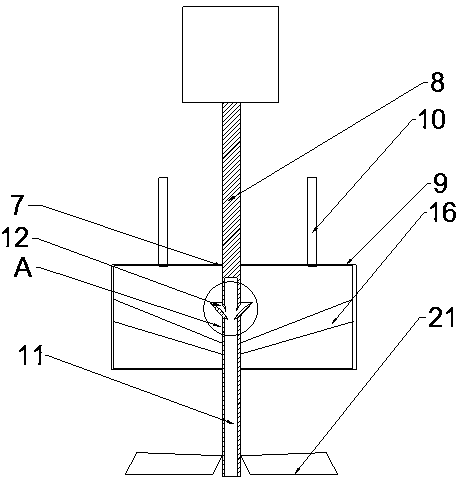

[0036] The second liquid injection device 7 includes a second stirring shaft 8 and a disc-shaped mixing table 9 fixed in the middle of the second stirring shaft, and the second stirring shaft passes through the mixing table along the central axis direction of the mixing table ; The mixing table is provided with a plurality of injection pipes 10 externally connected to the liquid storage tank; the bottom of the second stirring shaft is provided with a through...

Embodiment 2

[0041] A kind of intensive precision printing paste mixing system provided by the present invention comprises:

[0042] The first liquid injection device includes a fixed platform; the fixed platform is equipped with a liquid injection pipe and a first stirring shaft; the liquid injection pipe is used for externally connecting the liquid storage tank; the first stirring shaft passes through the central axis of the fixed platform through the fixed platform;

[0043] The second liquid injection device includes a second stirring shaft and a disk-shaped mixing table fixed in the middle of the second stirring shaft, and the second stirring shaft passes through the mixing table along the central axis direction of the mixing table; The mixing table is provided with a plurality of injection pipes connected to the liquid storage tank; the lower part of the second stirring shaft is provided with a through hole, and the top of the through hole extends to the upper side of the second stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com