Weaving method of silk yarn fabric

A technology of leno fabric and real silk, which is applied in the direction of leno fabric, leno fabric, fabric, etc., can solve the problem that cannot meet the requirements of fashionable color of leno fabric, the color cannot meet the fashion of the times, and the improvement of color purity and lightness cannot be fundamentally improved. Breakthrough and other problems, to achieve the effect of solving the inherent mercerized silk damage, excellent grades, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

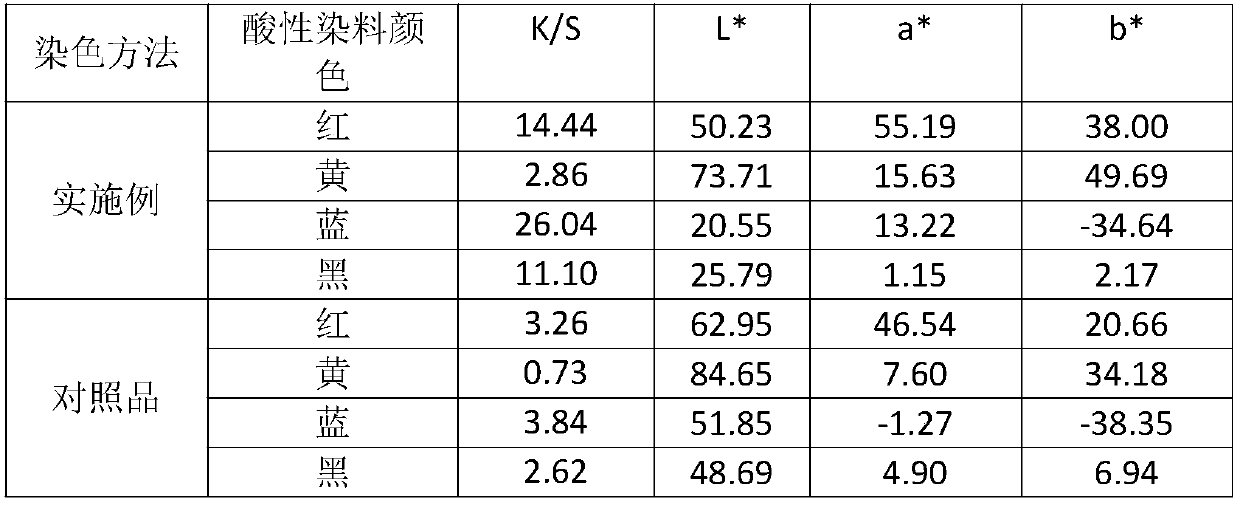

[0046] Product Name: Monochrome ribbed silk fabric (2 twisted)

[0047] Color: red, yellow, blue, black, using acid dyes

[0048] Warp density 40 / cm, weft density 32 / cm

[0049] Warp: Strip 84D (2 / 21D / 450Ts×2) 450T / z dyed

[0050] Degummed mulberry silk → winding → doubling → weak twisting (2 / 21D degummed mulberry silk) → twisting (2 / 21D degumming mulberry silk) 450T / s → shaping → twisting → dyeing → winding → double doubling (2 / 21D / 450T / s×2 degummed mulberry silk) → retwisting (2 / 21D / 450T / s×2 degummed mulberry silk) 450T / z→ shaping→ tube forming→ warping→ weaving→ finished product.

[0051] Weft: Strip 168D (4 / 21D / 450T / s×2) 450T / z splash color segment dyeing

[0052] Degummed mulberry silk→winding→doubling→weak twisting (4 / 21D degummed mulberry silk)→twisting (4 / 21D degummed mulberry silk) 450T / s→sizing→twisting→dyeing→winding→multiple (4 / 21D / 450T / s×2 degummed mulberry silk)→multi-twisting (4 / 21D / 450T / s×2 degummed mulberry silk) 450T / z→shape forming→tube forming→shaking...

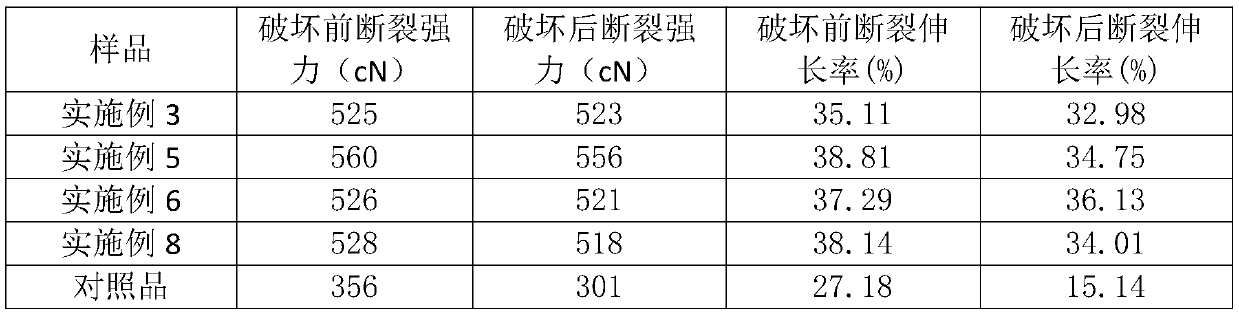

Embodiment 5

[0054] Product Name: Space-dyed monochrome splash-color rib weave silk fabric (4 warps)

[0055] Color: red, yellow, blue, black vegetable dyes

[0056] The warp density is 58 threads / cm, the weft density is 40 threads / cm

[0057] Warp: strips 84D (2 / 21D / 450Ts×2) 450T / z segment dyed splash color

[0058] Degummed mulberry silk→winding→doubling→weak twisting (2 / 21D degummed mulberry silk)→twisted silk (2 / 21D degummed mulberry silk) 450T / s→shaping→twisting→segment dyeing→color fixation→winding →Combination (2 / 21D / 450T / s×2 degummed mulberry silk)→Coupling (2 / 21D / 450T / s×2 degummed mulberry silk) 450T / z→Sizing→Cube forming→Warping→Weaving→Drop-off finished product.

[0059] Weft: Strip 168D (4 / 21D / 450T / s×2) 450T / z splash color segment dyeing

[0060] Degummed mulberry silk→winding→doubling→weak twisting (4 / 21D degummed mulberry silk)→twisting (4 / 21D degummed mulberry silk) 450T / s→shaping→twisting→splash color dyeing→fixation→winding →Combination (4 / 21D / 450T / s×2 degummed mulber...

Embodiment 6~9

[0070] Name of product: monochrome gauze rose fabric (3 warps)

[0071] Color: red, yellow, blue, black vegetable dyes

[0072] Warp density 40 / cm, weft density 34 / cm

[0073] Warp: strip 62D {(1 / 31D degummed tussah silk) 750Ts×2}650T / z

[0074] Degummed tussah silk → winding → paralleling → weak twisting (1 / 31D) 750Ts → twisting (1 / 31D) 750Ts → shaping → twisting → section dyeing → color fixing → winding → multiple bonding (1 / 31D )750T / s×2→multi-twisting (1 / 31D / 750Ts×2)650T / z→shaping→tube forming→warping→weaving→finished product.

[0075] Weft: strips 124D {(2 / 31D degummed tussah silk) 2200Ts×2}10T / z

[0076] Degummed tussah silk→winding→doubling (2 / 31D)→twisting (2 / 31D) 2200T / s×2→shaping→twisting→splash color dyeing→fixing color→winding→multiplexing (2 / 31D ) 2200T / s×2→multi-twisting (2 / 31D / 2200Ts×2) 10T / z→shape forming→tube forming→shaking→weaving→looming finished product.

[0077] The amount of dyes used for dyeing, segment dyeing or splash dyeing described in the abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com