Coal ball broken material collection device

A collection device, briquettes technology, applied in the direction of removing smoke and dust, grain processing, chemical instruments and methods, etc., can solve the problems of waste, heavy workload, loss of human and material resources, etc., and achieve the effect of thorough collection and reduction of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

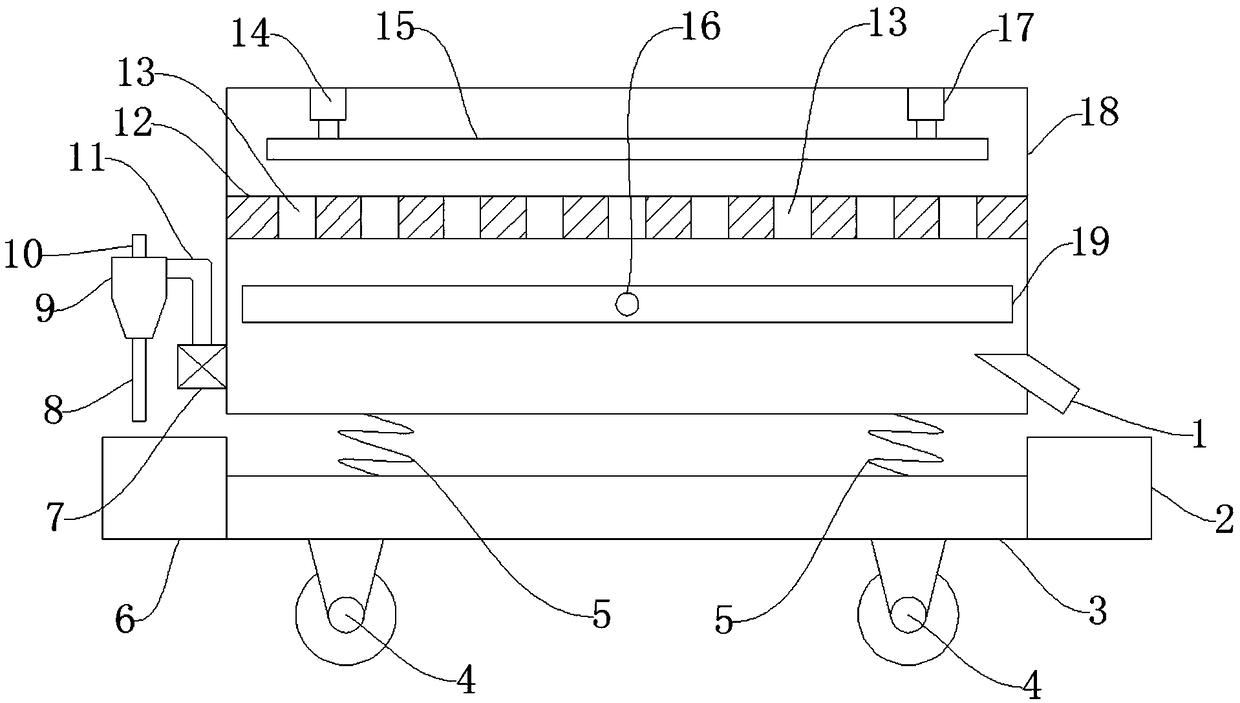

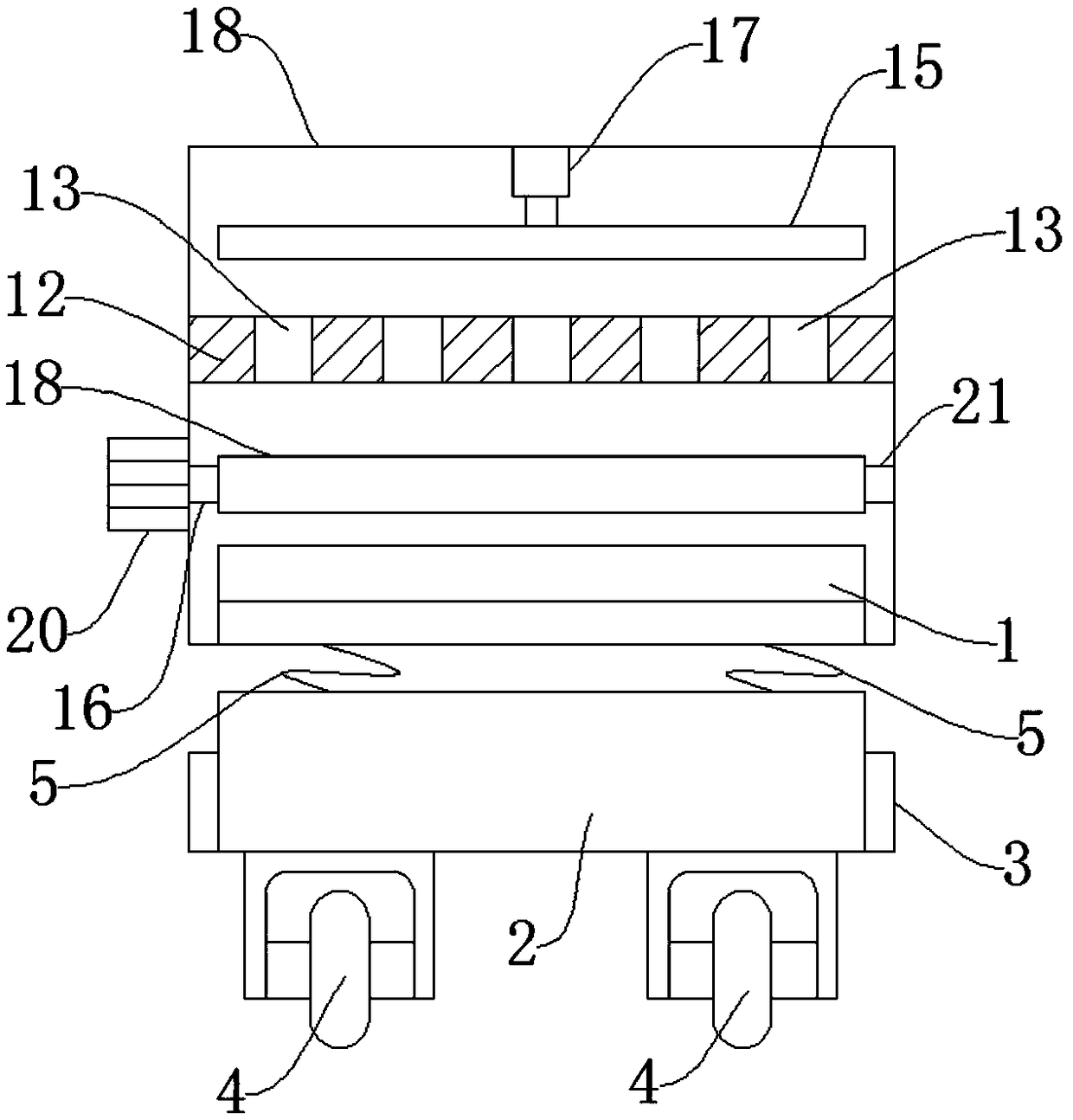

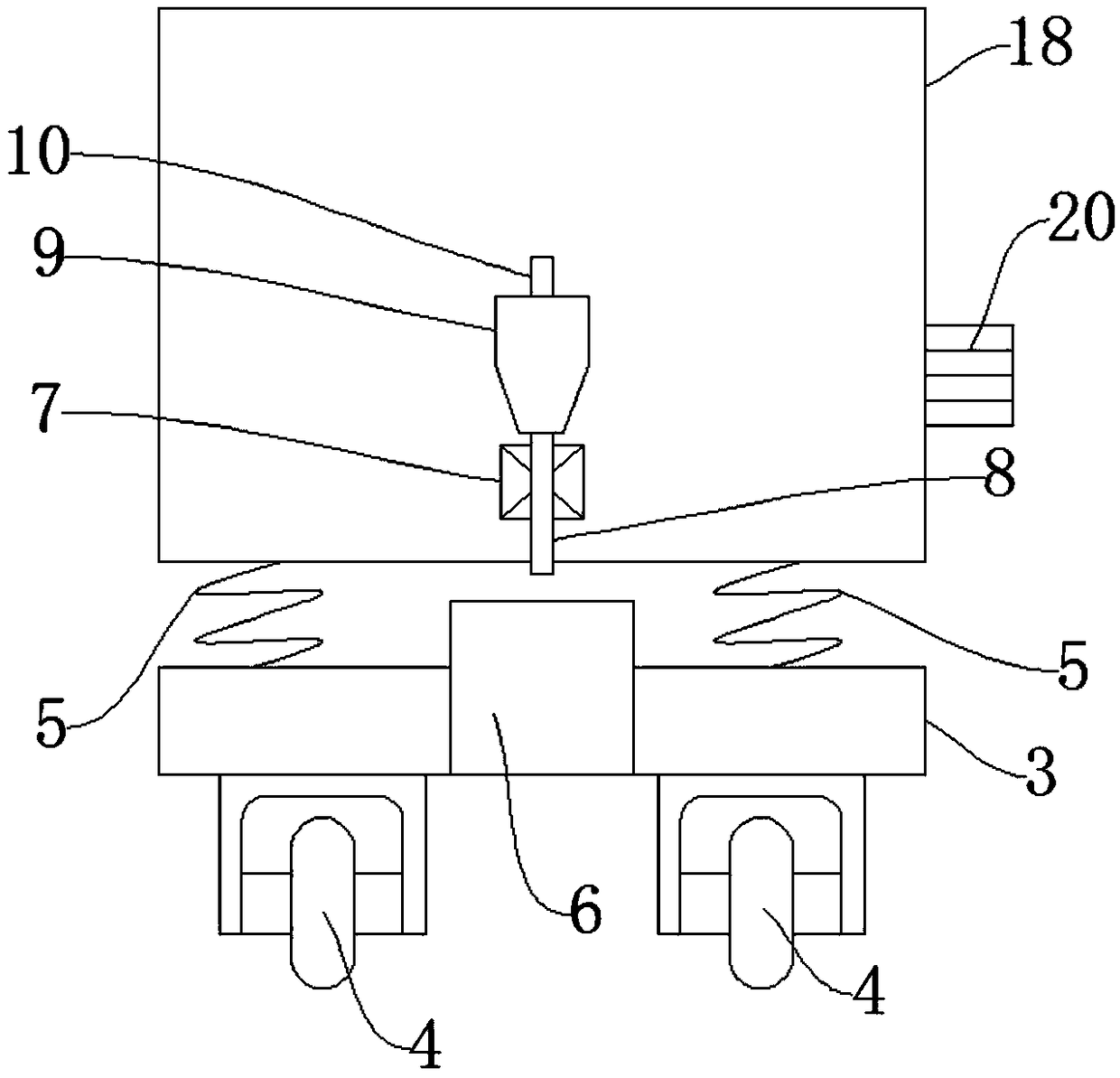

[0019] The present invention will be further described below in conjunction with accompanying drawing:

[0020] Such as Figure 1-Figure 3 As shown, a briquette crushing debris collection device includes a debris discharge pipe 1, a debris collection box 2, and a bottom plate 3. Four universal drive wheels 4 are arranged at the four corners below the bottom plate 3, and the universal drive wheels 4 provide power. function, the four corners above the base plate 3 are provided with four damping springs 5, and the damping springs 5 act as a shock absorber; one side of the base plate 3 is provided with a debris collection box 2, and the debris collection box 2 plays the role of collecting debris, and the base plate 3 is kept away from the A powder collection box 6 is arranged on one side of the debris collection box 2, and the powder collection box 6 functions to collect dust, and a housing 18 is arranged above the shock absorbing spring 5, and the housing 18 plays a supporting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com