Layer-by-layer optional dual mode cleaning device in metal 3D printing

A 3D printing and cleaning device technology, which is applied in the direction of dry gas arrangement, cleaning method and utensils, cleaning method using liquid, etc., can solve the problems of cleaning the device too hard, delaying the use time, single function, etc., to prevent dust from entering, good Shock-absorbing effect, effect of improving drug efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

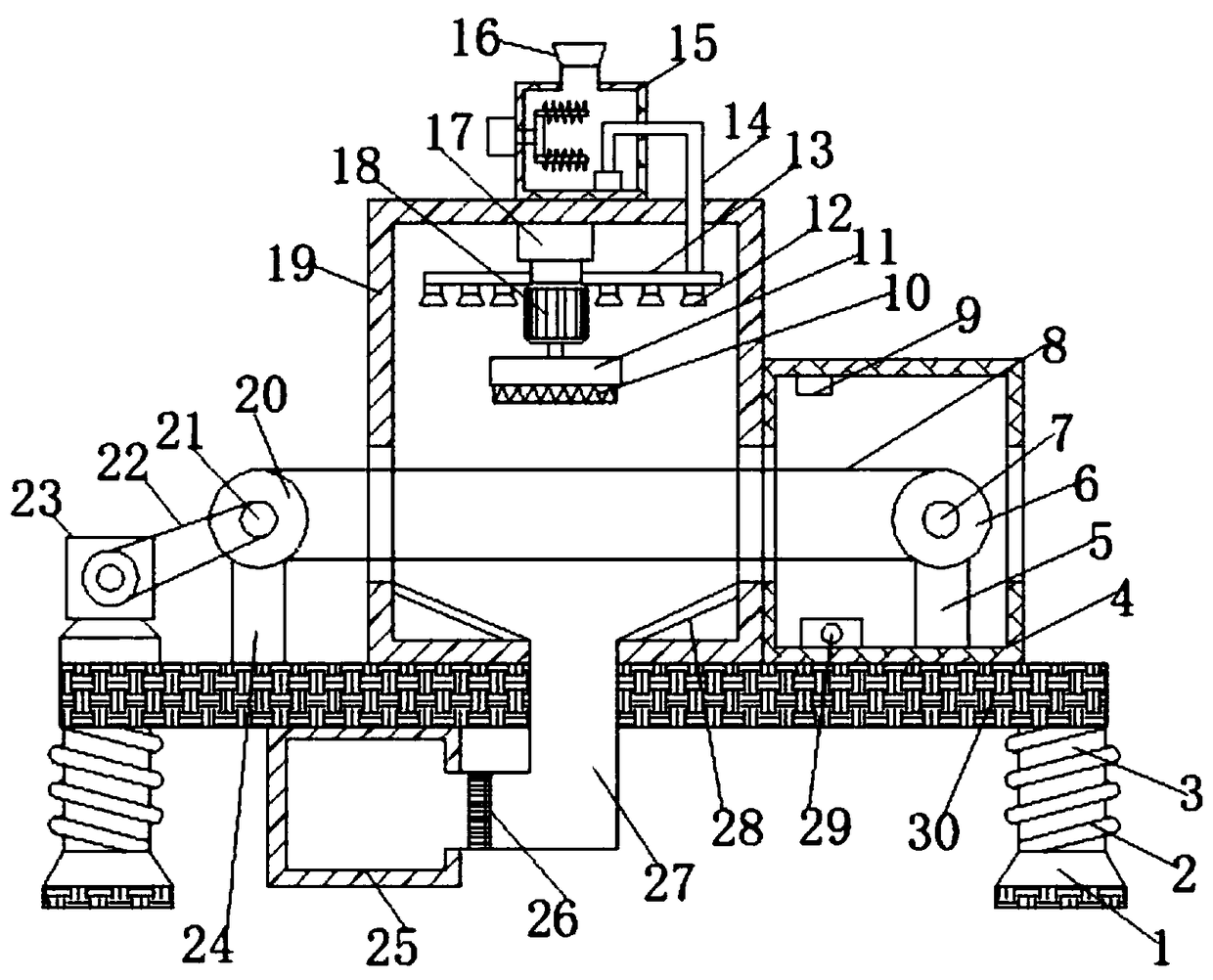

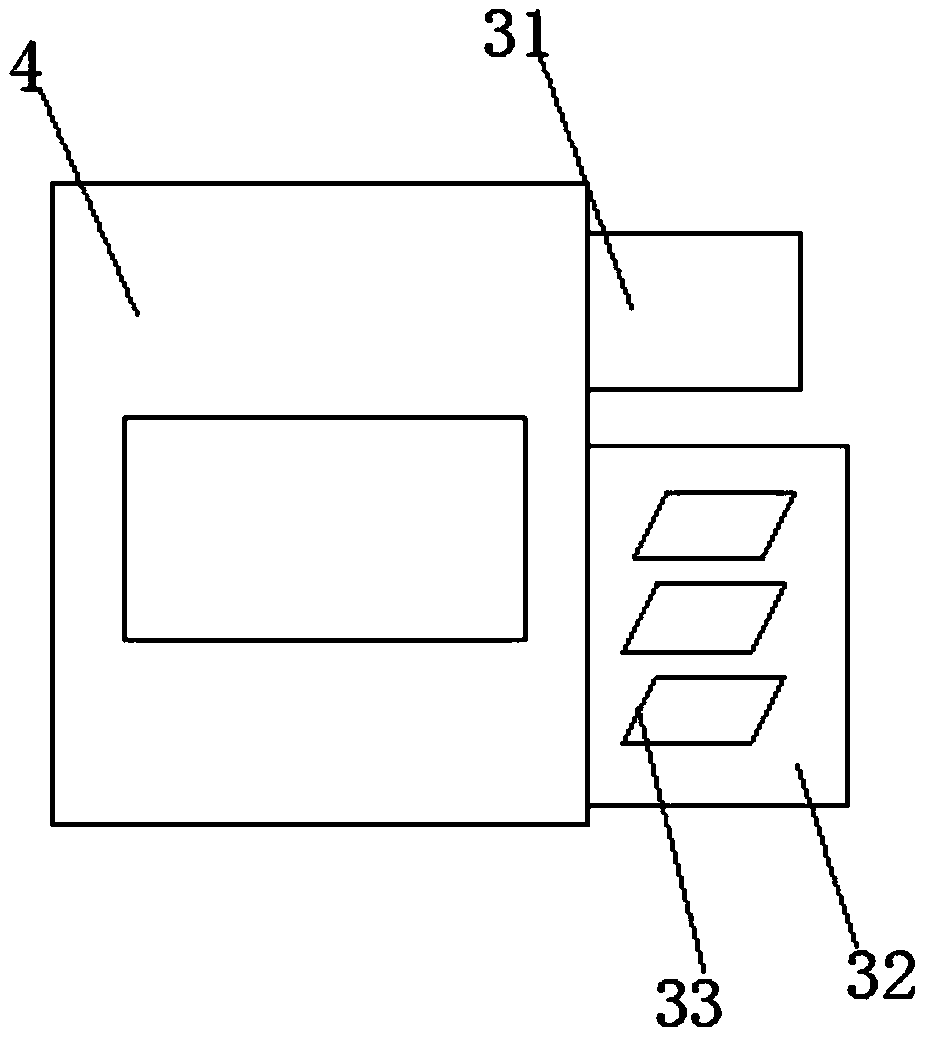

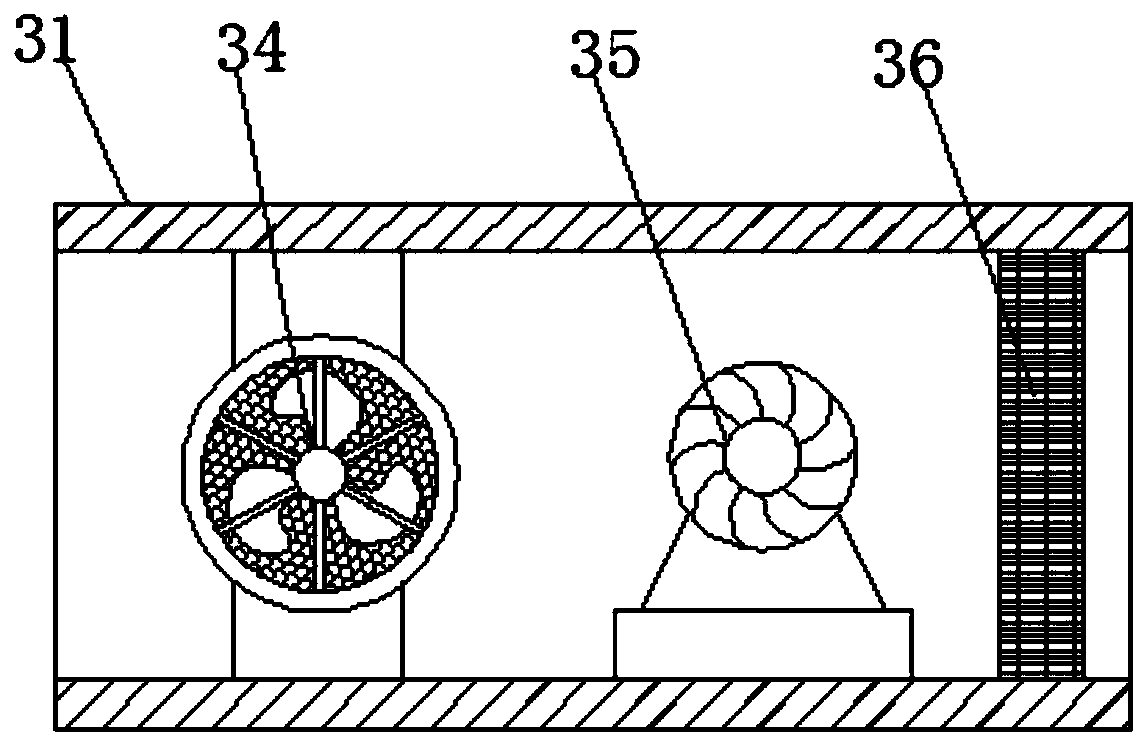

[0028] refer to Figure 1-5 , a layer-by-layer selective dual-mode cleaning device in metal 3D printing, comprising a bottom plate 30, a cleaning box 19 and a drying box 4, the top outer wall of the bottom plate 30 near the middle is fixed with a cleaning box 19 and a drying box. Dry box body 4, and the side outer wall that cleaning box body 19 and drying box body 4 are close to each other is all provided with rectangular hole communication hole, and the side outer wall that cleaning box body 19 and drying box body 4 are far away from each other is opened respectively. There is a feed port and a discharge port, and the top inner wall of the cleaning box body 19 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com