Lithium battery current collecting plate shaping and bending device

A bending device and collector plate technology, which is applied to the feeding device, positioning device, storage device, etc., can solve the problems of high scrap rate, deflection of the collector plate, easy to place deviation, etc., so as to improve the qualified rate of products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

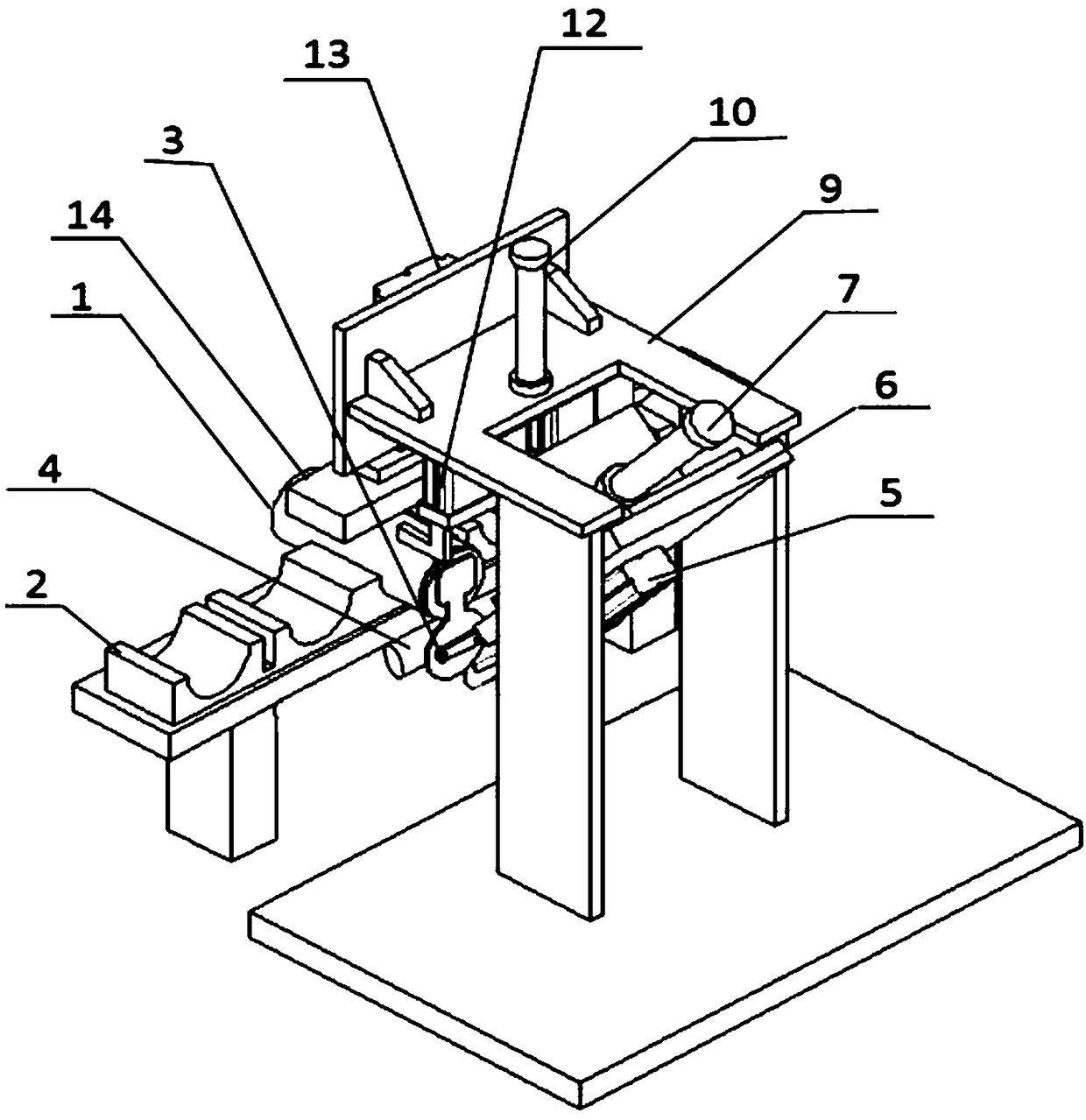

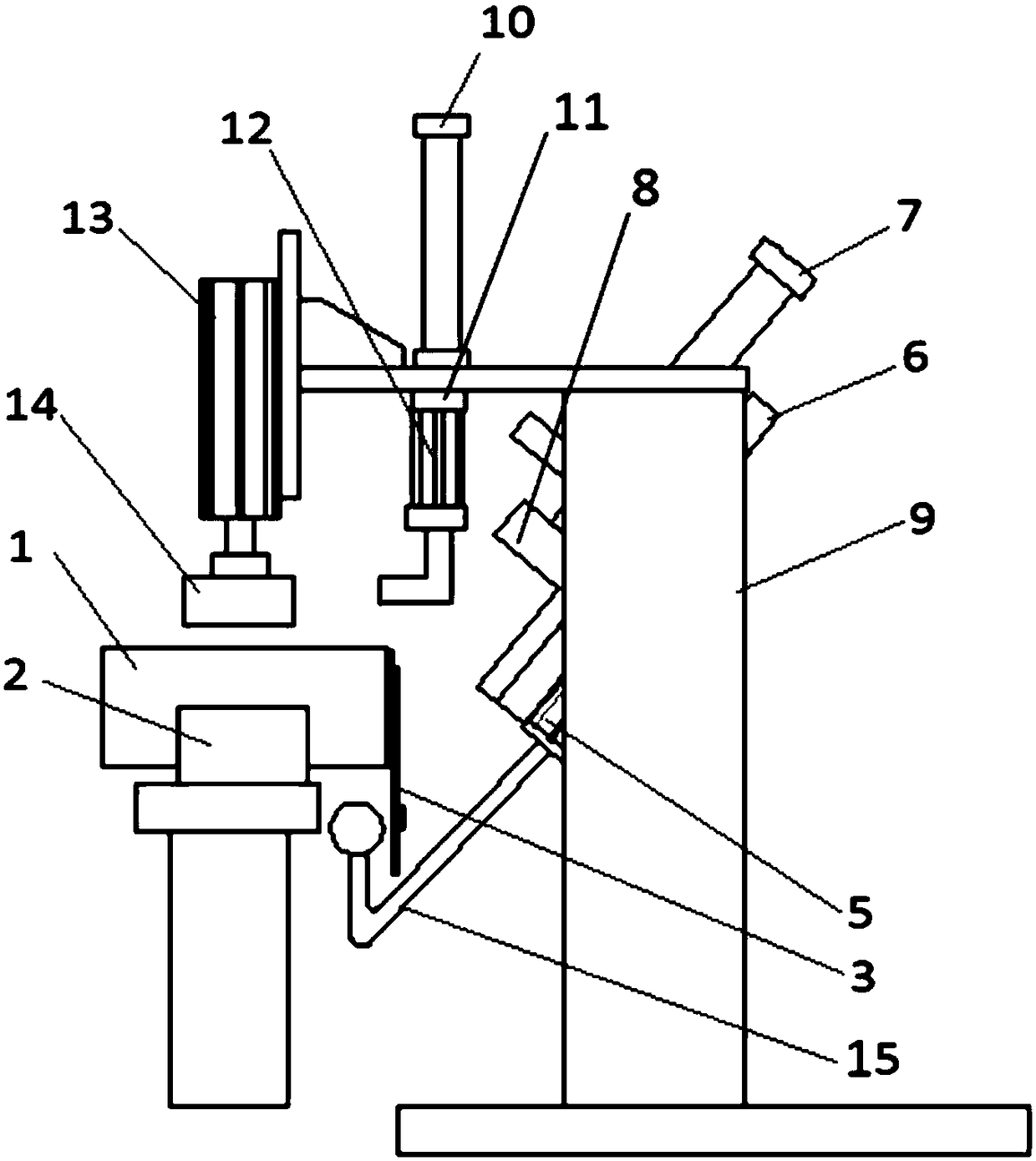

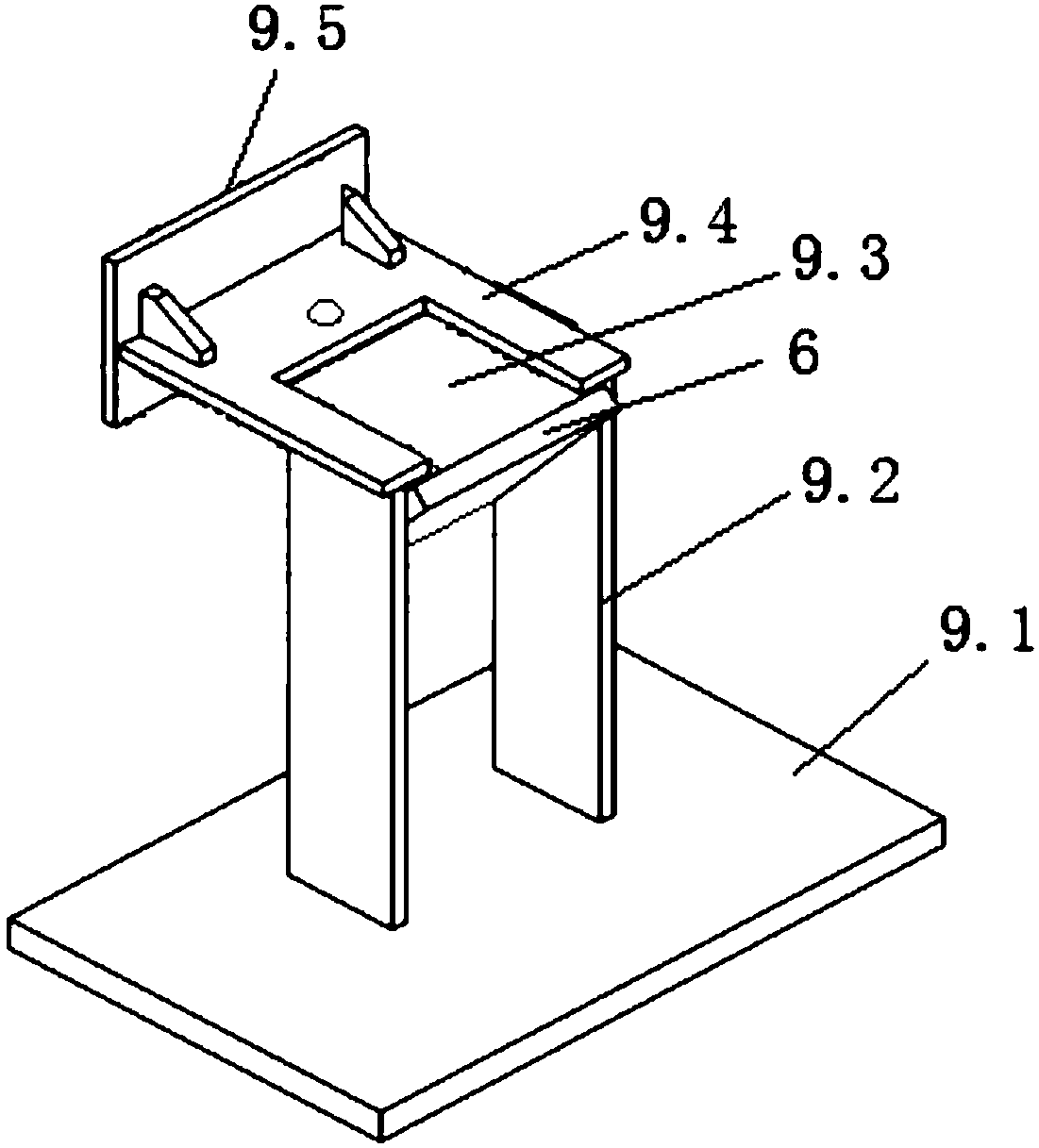

[0020] Such as figure 1 , 2 As shown, a lithium battery collector plate shaping and bending device includes a battery tank 2 for loading batteries 1 and moving along with the conveying line, a frame 9 is fixed on one side of the conveying line, and the end of the battery 1 A current collecting plate 3 is welded; a pressing device 13 for fixing the battery 1 is fixed on the frame 9 directly above the battery 1, and a pair of current collecting plates is fixed on the frame 9 directly above the current collecting plate 3. An adjustment mechanism for adjusting the position of the plate 3; a brace device for fixing the collector plate 3 and a bending mechanism for bending the collector plate 3 are also provided on the frame 9.

[0021] In a further solution, the top end of the adjustment mechanism is connected to the lifting mechanism fixed on the frame 9 .

[0022] In a further scheme, the adjustment mechanism is a finger cylinder 12, the pressing device is a pressing cylinder 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com