Distributed hub driving electric car chassis structure

A technology of wheel drive and electric vehicles, which is applied in the direction of electric steering mechanism, brake components, brakes, etc., can solve the problems of no steering system design and adjustment, and achieve the effects of simple structure, improved handling stability, and good steering characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The connection mode of this embodiment will be described in detail below in conjunction with the accompanying drawings.

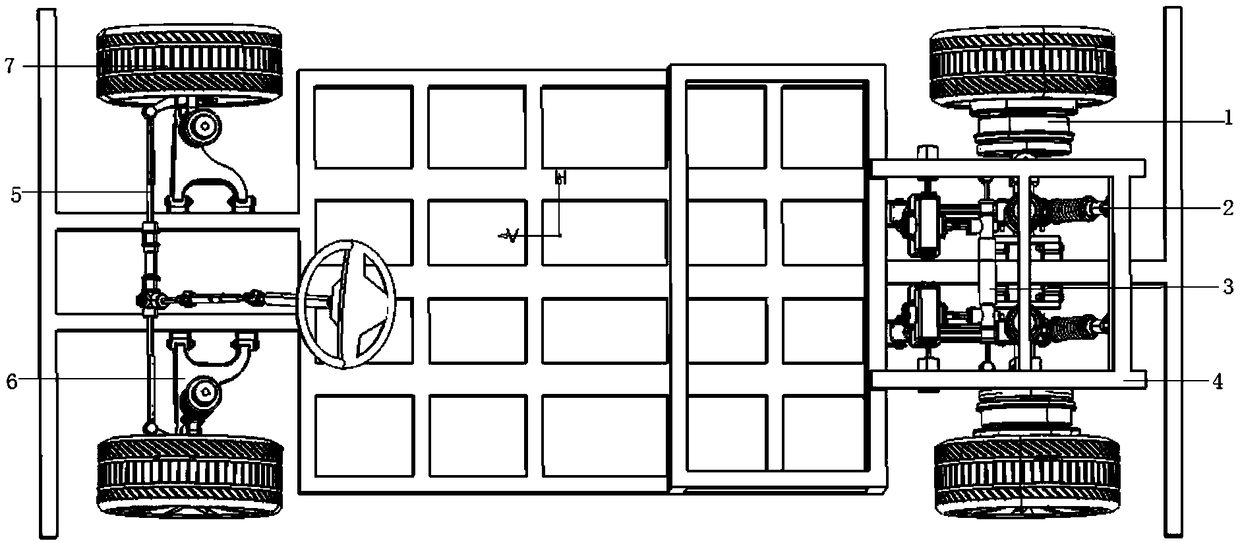

[0026] figure 1 It consists of wheel drive and brake integrated system 1, rear suspension 2, rear steering 3, frame 4, front steering 5, front suspension 6 and wheel hub braking system 7, etc.

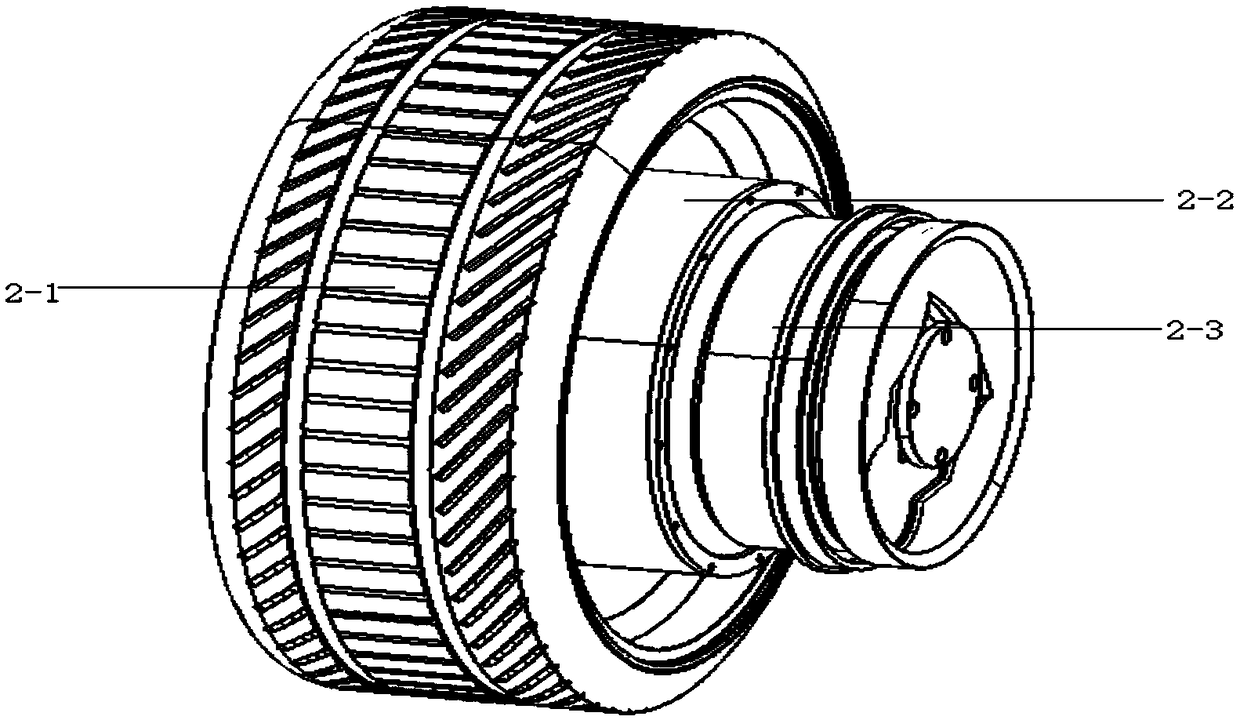

[0027] figure 2 It is the structural diagram of the hub drive and brake integrated system 1, which is composed of the wheel 2-1, the hub motor 2-2, and the brake 2-3. The wheel 2-1 and the hub motor 2-2 are fixedly connected by bolts, and the hub motor The outer rotor of 2-2 is bolted to brake 2-3.

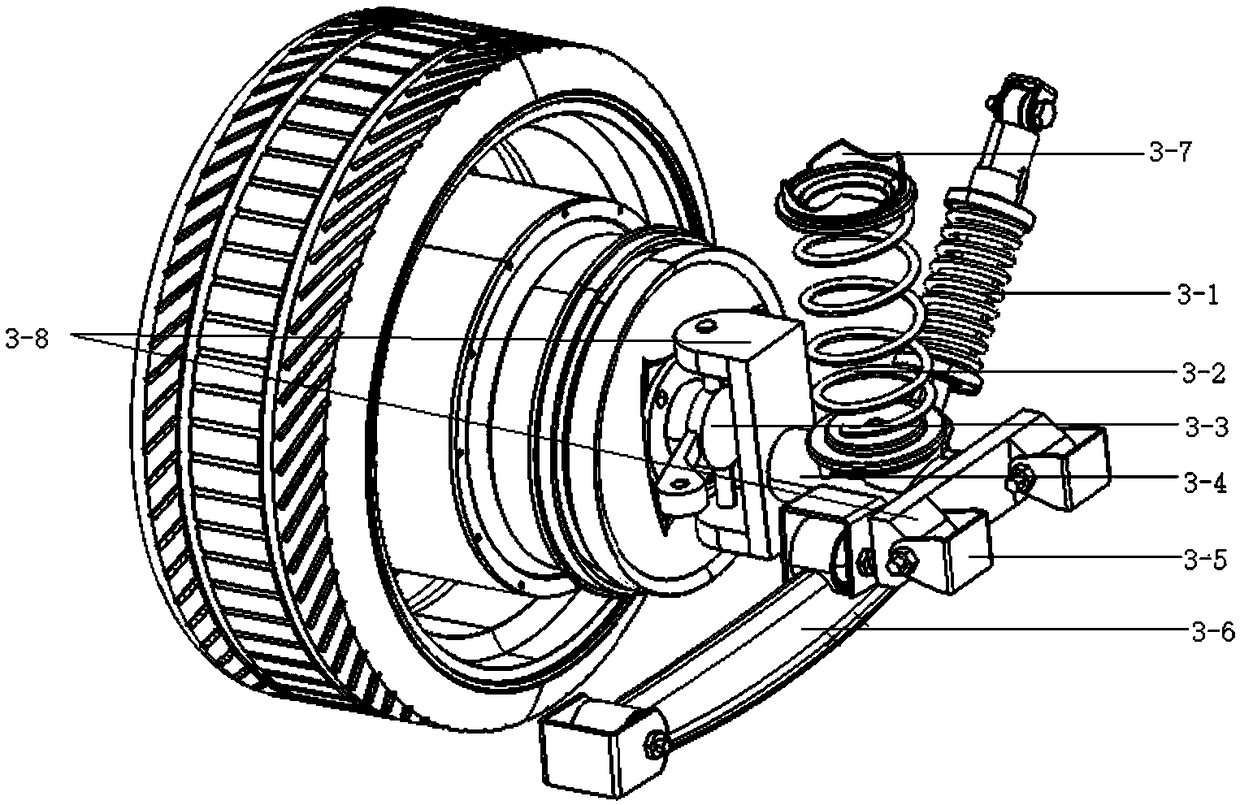

[0028] image 3 It is the structural diagram of the rear suspension 2, which mainly consists of a shock absorber 3-1, a shock absorbing spring 3-2, a steering knuckle 3-3, a support shaft 3-4, a lifting lug 3-5, a support arm 3-6, and a base 3-7, concave rotating element 3-8, etc., the steering knuckle 3-3 is connected with the concave rotating element 3-8 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com