Backpack type air intake duct with grille inlet

A kind of air intake and piggyback technology, which is applied in the direction of combustion of the air intake of the power plant, can solve the problems affecting the survivability of the aircraft, the unfavorable stealth of the aircraft, etc., and achieve the effects of small distortion, meeting the matching requirements, and good aerodynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

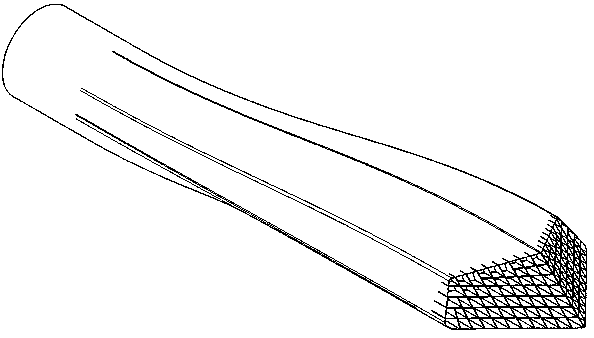

[0026] The application is a piggyback grille inlet air duct, which includes a transition section 2, an inner pipeline design section 3 and an equal straight section 5 from the front end to the rear end. The front end of the transition section 2 is equipped with a grille 1; the inner pipeline design section 3 The front end is connected to the front end of the inner pipeline design section 3, and the rear end of the inner pipeline design section 3 is connected to the equal straight section 5.

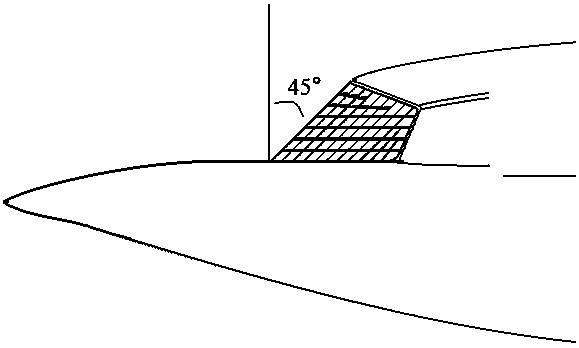

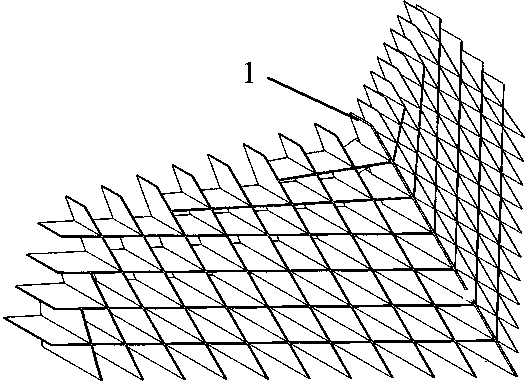

[0027] Grille 1 is installed at the inlet of the air inlet. In order to further reduce the RCS, the symmetrical front edge of the grille is tilted back by 45°, as shown in figure 2 . The design principle of the grille is, based on the plane formed by the symmetrical front edge of the grille and the front edge of the inlet lip, the design diameter of the grille is about 25mm, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com