Conveyor belt and carrier mounting structure, and feeding buffer device comprising same

A technology of installation structure and conveyor belt, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of inability to meet product testing requirements, unstable product quality, poor transmission stability, etc., achieve good driving effect and save equipment Cost, the effect of increasing the intensity of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

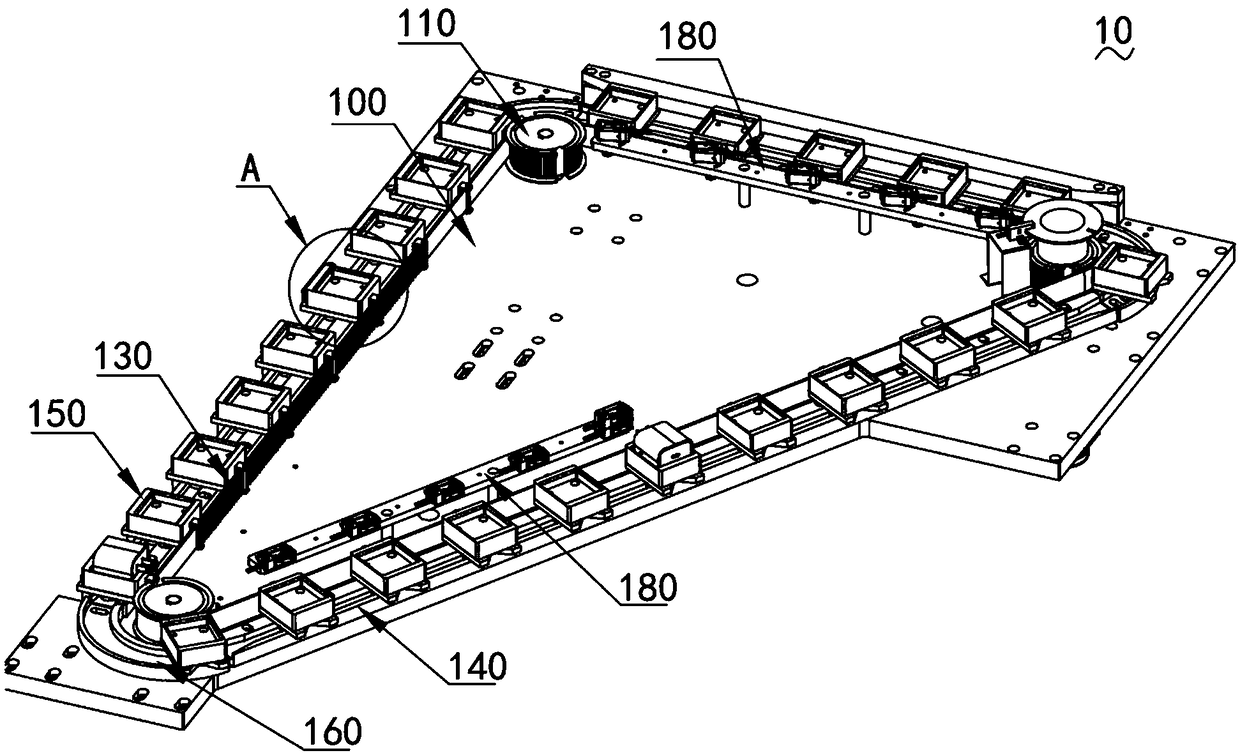

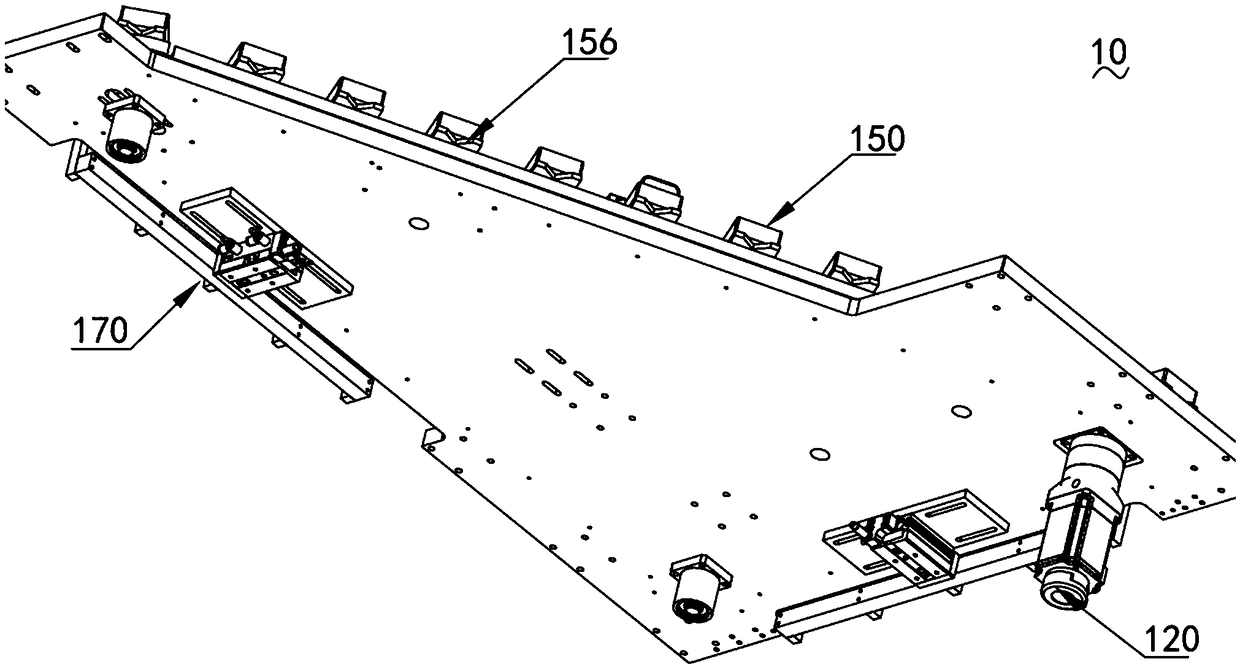

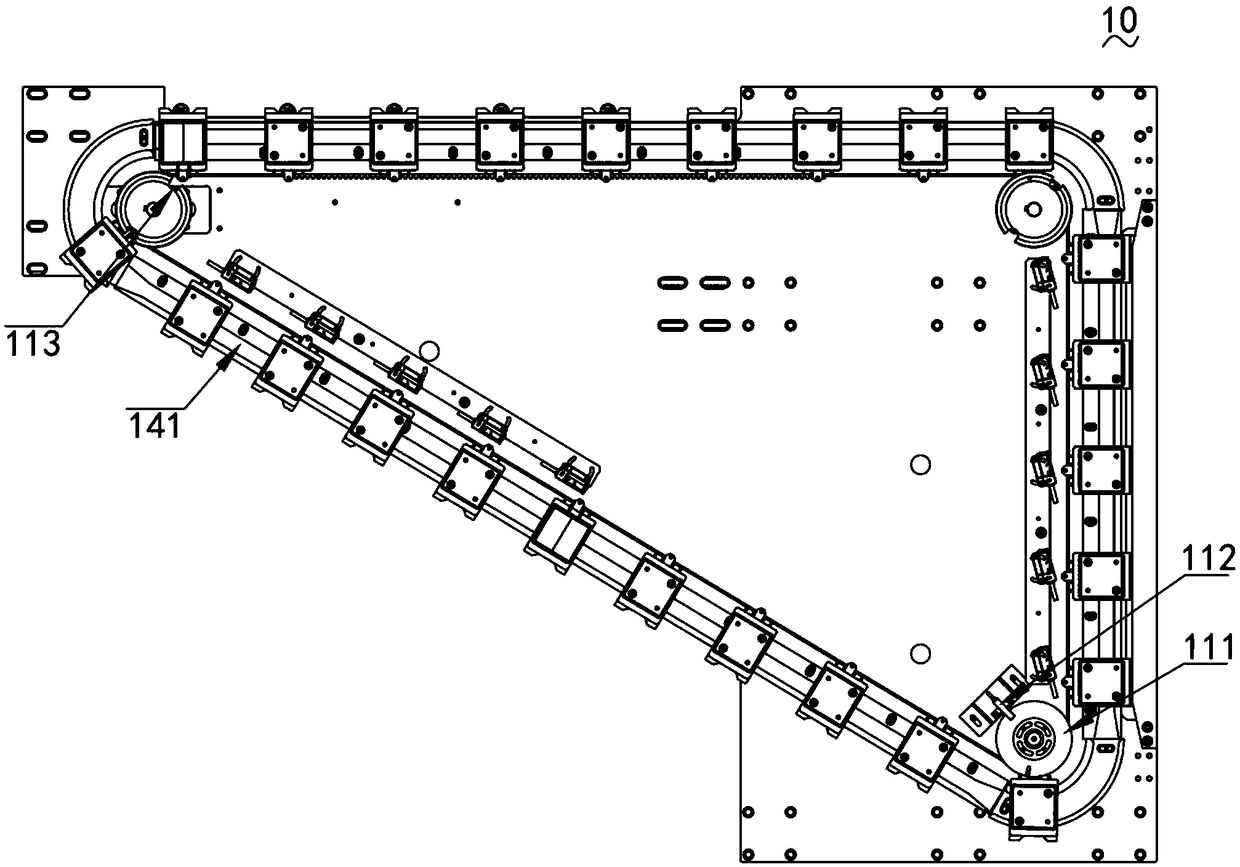

[0027] Such as Figure 1 ~ Figure 3 As shown, they are three-dimensional schematic diagrams of different viewing angles of the present invention.

[0028] The loading and buffering device 10 includes a workbench 100, a number of synchronous guide wheels 110 arranged on the workbench 100, at least two sets of synchronous guide wheels 110 are driven and connected to a drive assembly 120, and the conveyor belt 130 is connected to the synchronous guide wheels 110 by synchronous transmission. The workbench 100 is provided with a transmission guide rail 140 near the side of the conveyor belt 130, the carrier 150 is connected to the conveyor belt 130 and driven on the transmission guide rail 140, and the transmission guide rail 140 is provided with a curved groove 160 near the synchronous guide wheel 110, so The workbench 100 is provided with a positioning component 170 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com