Tower crane blind area ultrathin steel plate shear wall hoisting device and hoisting method thereof

A steel plate shear wall and lifting device technology, which is applied in hoisting devices, hoisting devices, cranes, etc., can solve the problems that the boom tower crane cannot be installed in place, the installation cost is high, and the installation time is long, etc., so as to achieve flexible and convenient installation and disassembly , Low construction cost, and the effect of reducing the cost of measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with embodiment:

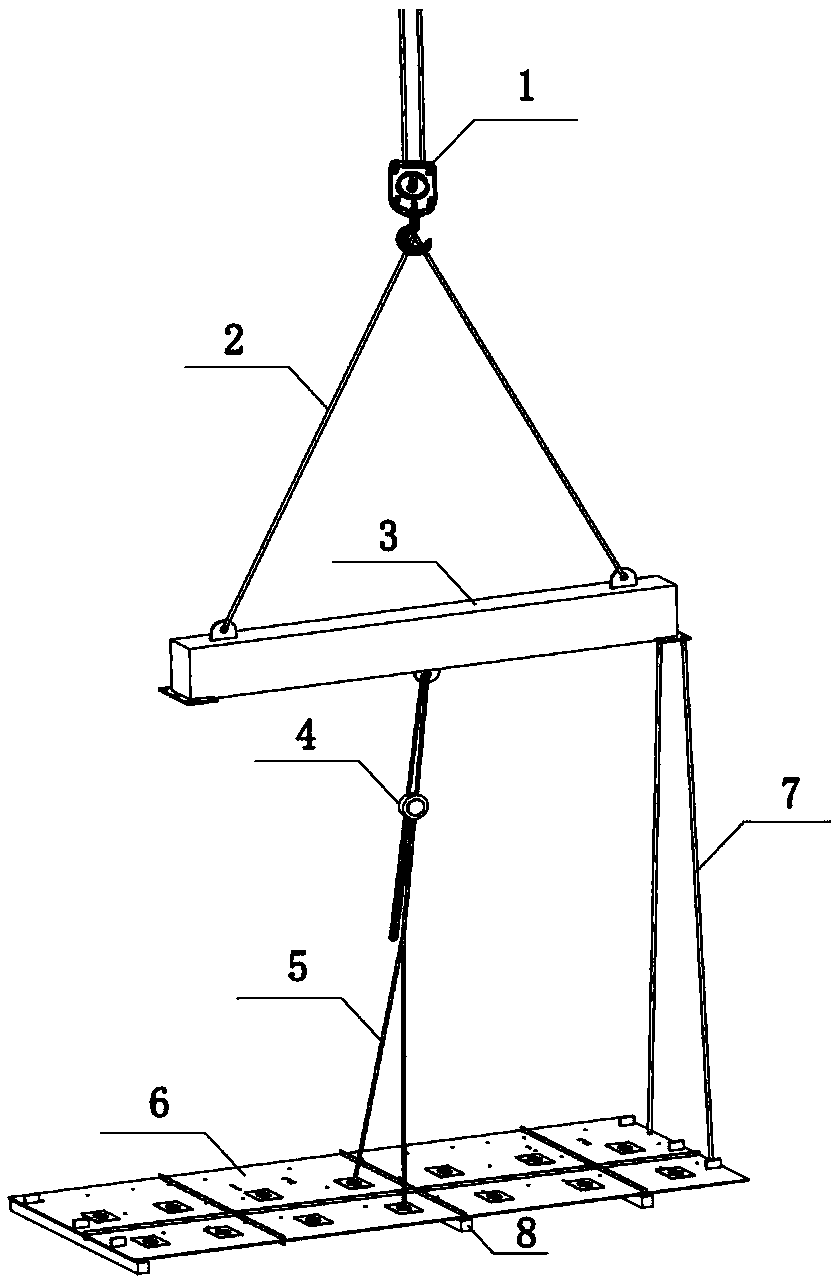

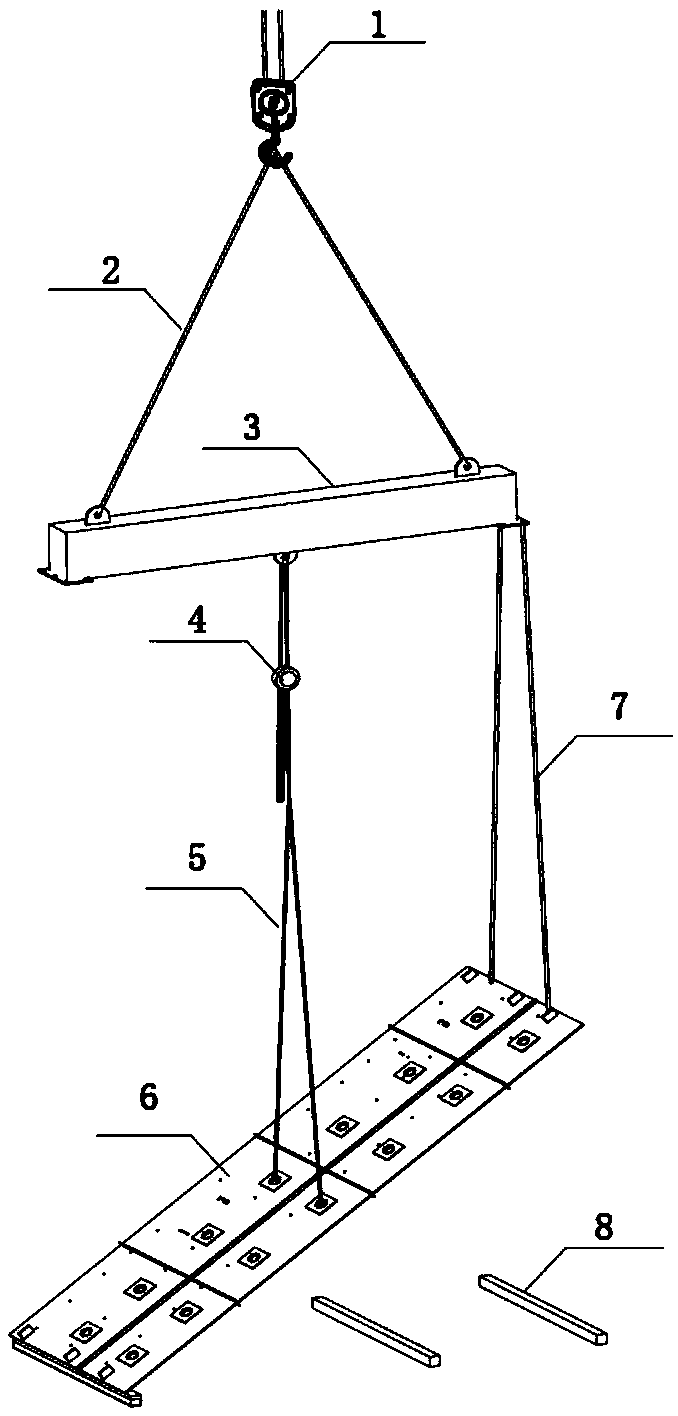

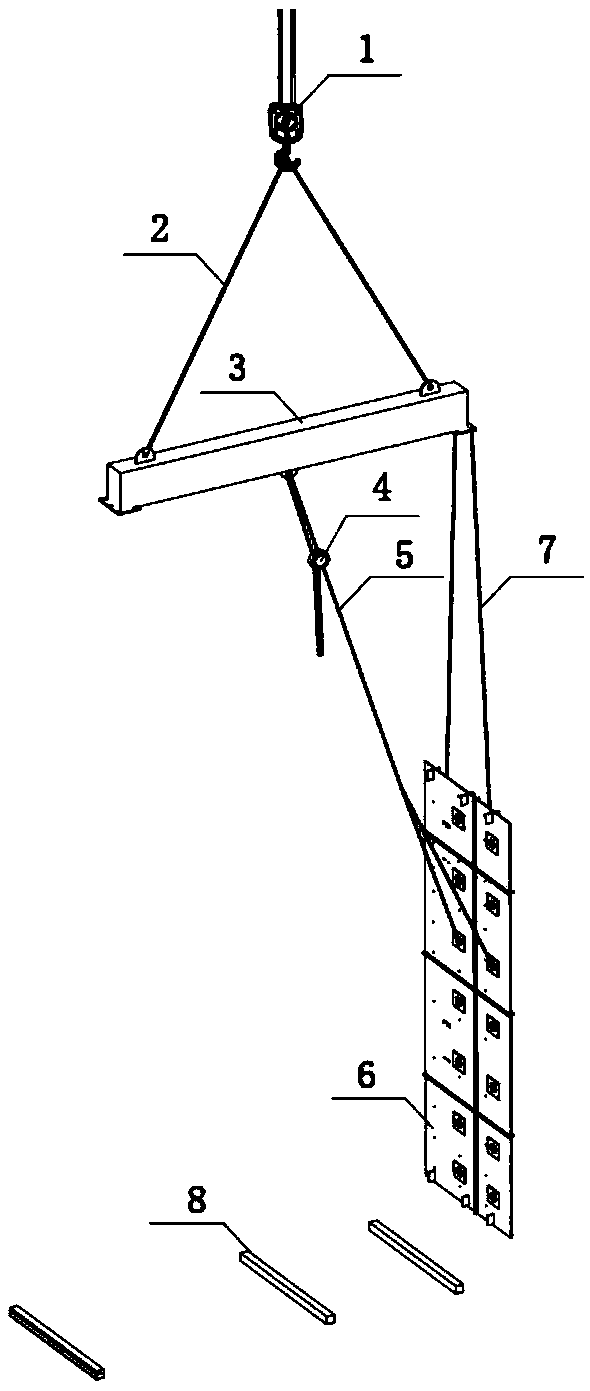

[0023] The lifting device of the present invention comprises a shoulder pole beam 3, and the pole pole beam 3 adopts a tower crane climbing steel beam, and two pole beam slings 7 for connecting with one end of the steel plate shear wall 6 are connected to one end of the lower surface of the pole pole beam 3, and An electric hoist 4 is arranged in the middle of the lower surface of the beam 3, and two electric hoist rigging 5 for connecting with the middle of the steel plate shear wall 6 are connected to the hooks of the electric hoist 4, and two electric hoist slings 5 are connected to the upper surface of the shoulder beam 3 respectively. The hoisting sling 2 connected to the boom tower crane hook 1 also includes a plurality of sleepers 8 for padding up the steel plate shear wall 6 .

[0024] Lifting lugs are welded in the middle of the lower surface of the shoulder pole beam 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com