Assembly type simply-supported box girder end crossbeam structure

A prefabricated, end-beam technology, used in bridges, bridge materials, bridge construction, etc., can solve the problems of poor recovery quality of roof notch, inability to remove inner mold, affecting structural stress, etc. The effect of pouring quality and speeding up construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in combination with specific embodiments.

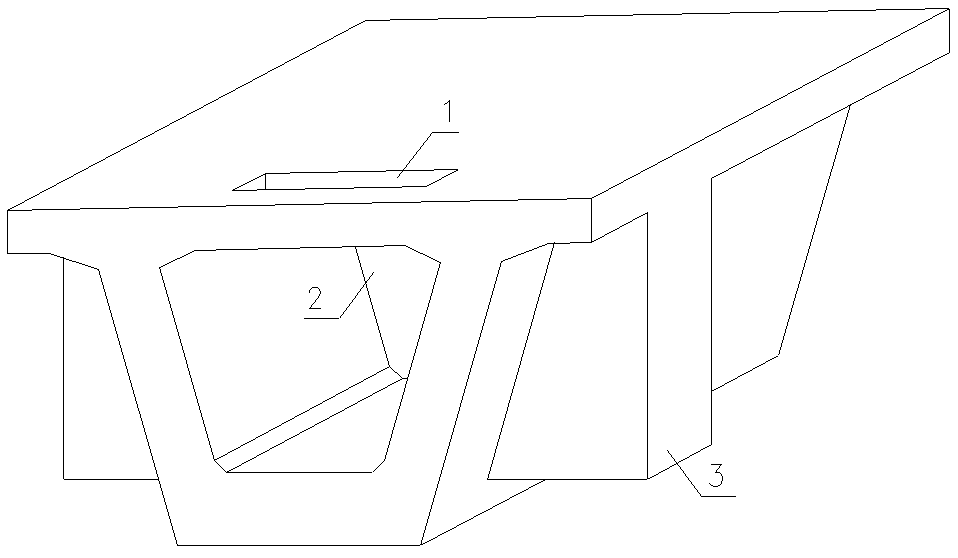

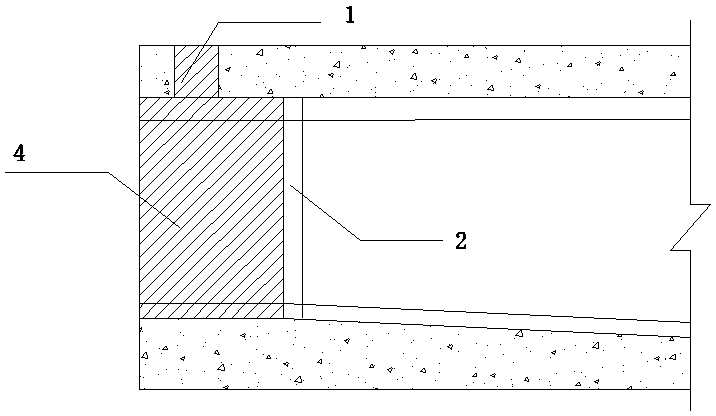

[0022] The invention relates to an assembled simply supported box girder end beam structure, which comprises a box girder. The bottom plate of the box girder is evenly thickened from the inside to the outside, so that the cross section of the box is gradually shrunk from the inside to the outside. The box girder is composed of an upper top plate, a lower bottom plate and webs on both sides, and horizontal and vertical prefabricated end beams are arranged on the outside of the webs. The box girder and the prefabricated end beam are integrally casted at one time. The side of the prefabricated end beam is vertically coplanar with the top plate, and the bottom surface is higher than the bottom plate.

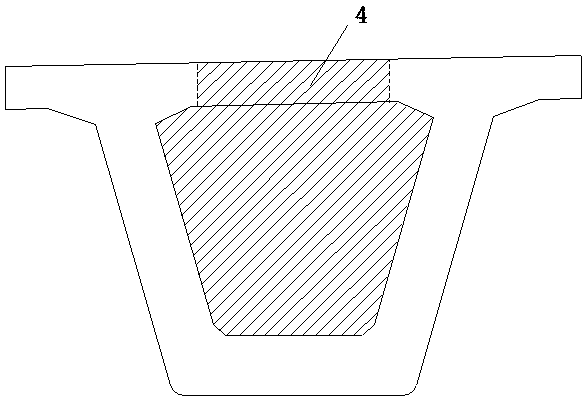

[0023] The box girder is provided with horizontal and vertical box inner plug boards, and the box inner plug boards are fixed in the box by mortar.

[0024] The box girder to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com