ZnMgO ultraviolet detector and preparation method thereof

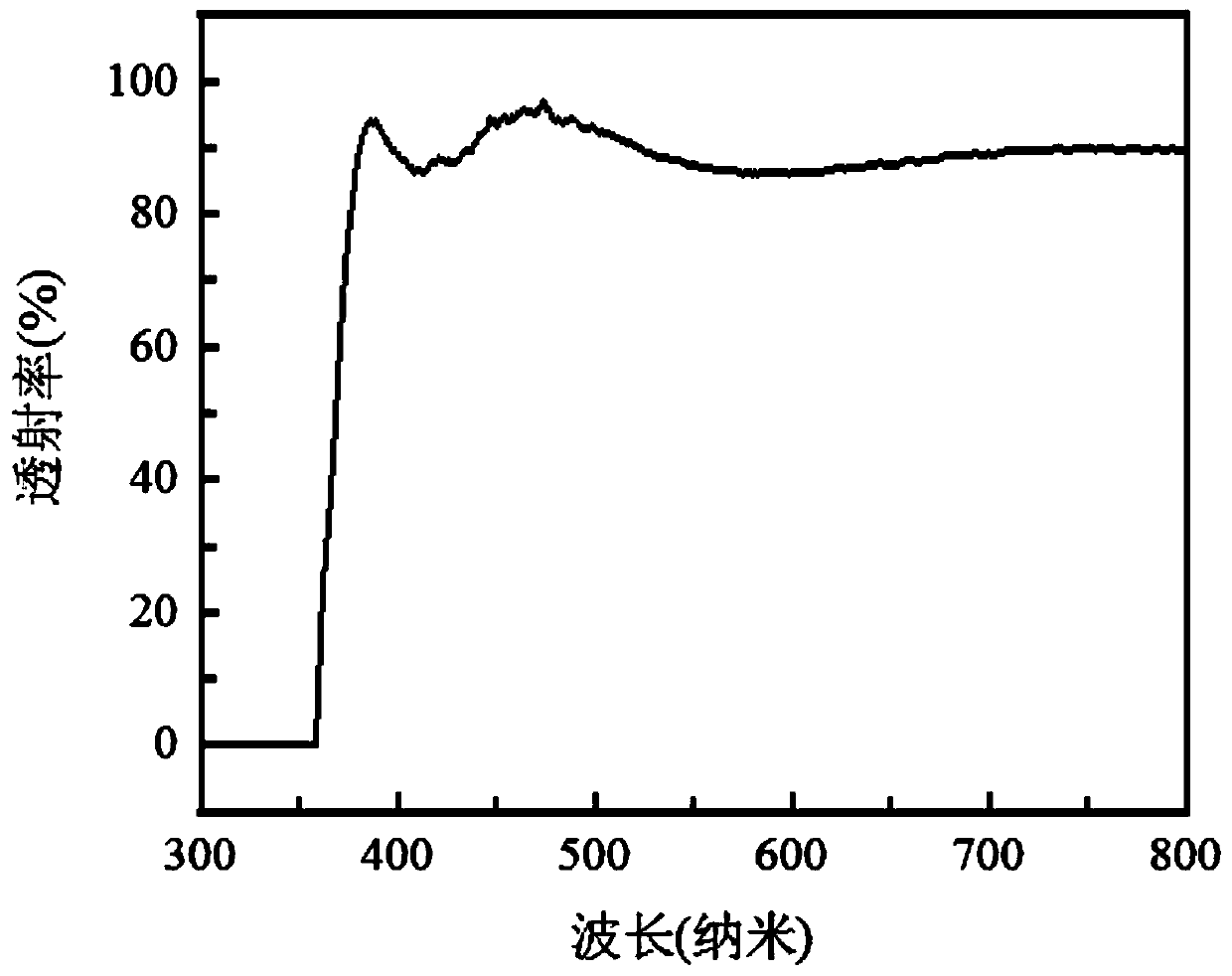

A technology of ultraviolet detectors and interdigitated electrodes, which is applied in the direction of semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of unstable devices, poor performance, high dark-state current, etc., and reach the absorption cut-off edge Steep, flat surface, low dark current effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

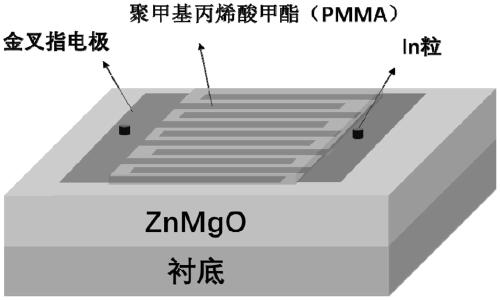

[0091] The present invention also provides a kind of preparation method of ZnMgO ultraviolet detector, comprises the following steps:

[0092] 1) Under the condition of excess oxygen, after the organic zinc source and the organic magnesium source are carried out chemical vapor deposition on the heating substrate, the substrate with ZnMgO thin film is obtained;

[0093] 2) On the ZnMgO film obtained in the above steps, an interdigitated electrode mask is first formed, and then a metal layer is formed, and then the mask is removed to form an interdigitated electrode layer;

[0094] 3) Composite the polymer layer on the interdigitated electrode of the interdigitated electrode layer obtained in the above steps, and press In particles on the non-interdigitated electrodes to obtain the ZnMgO ultraviolet detector.

[0095] In the above-mentioned preparation method of the present invention, the structure, composition, parameters and optimization principles of the ZnMgO ultraviolet det...

Embodiment 1

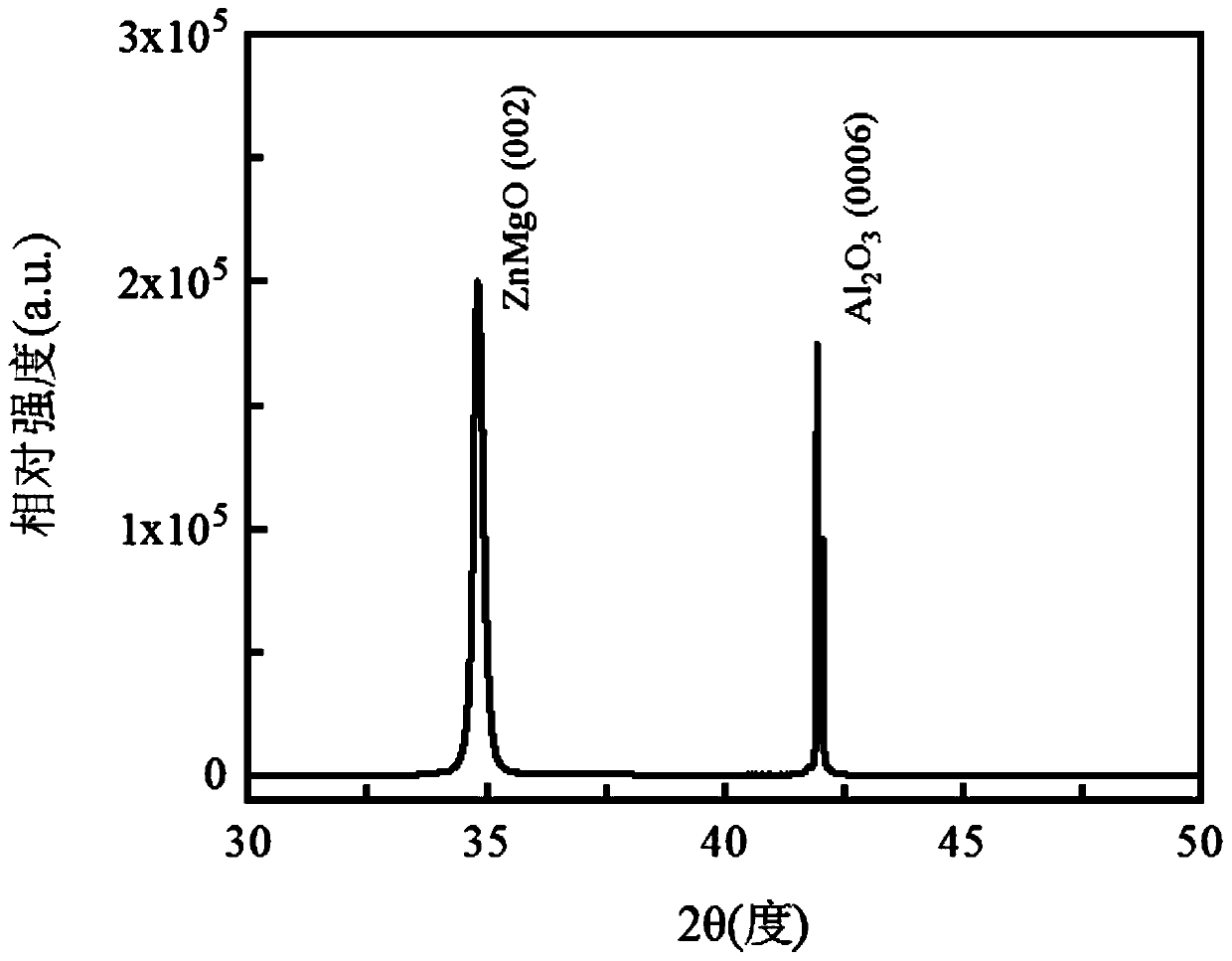

[0115]Put the cleaned sapphire substrate into the MOCVD growth chamber, adjust the growth temperature to 500°C, and the pressure to 2x10 3 Pa. Diethyl zinc was used as the zinc source, dimethylmagnesocene was used as the magnesium source, the carrier gas flow rate of the zinc source was 10 sccm, and the carrier gas flow rate of the magnesium source was 1 sccm. The flow rate of oxygen is 200 sccm, which is much greater than the flow rate of zinc source and magnesium source. After growing for 2 hours, turn off the organic source and oxygen, and lower the substrate temperature to room temperature at 0.2°C / s to obtain a ZnMgO thin film.

[0116] On the ZnMgO thin film material, 50 pairs of interdigitated electrode masks with a pitch of 10 μm and a length of 500 μm were formed using negative resist lithography. The obtained sample was put into a small coating machine, and metal gold was sputtered under the condition of a pressure of 4Pa and a current of 8mA. The colloidal mask i...

Embodiment 2

[0134] Put the cleaned sapphire substrate into the MOCVD growth chamber, adjust the growth temperature to 700°C, and the pressure to 2x10 3 Pa. Diethyl zinc was used as the zinc source, dimethylmagnesocene was used as the magnesium source, the carrier gas flow rate of the zinc source was 10 sccm, and the carrier gas flow rate of the magnesium source was 1 sccm. The flow rate of oxygen is 200 sccm, which is much greater than the flow rate of zinc source and magnesium source. After growing for 2 hours, turn off the organic source and oxygen, and lower the substrate temperature to room temperature at 0.2°C / s to obtain a ZnMgO thin film.

[0135] The ZnMgO thin film prepared in Example 2 of the present invention was characterized.

[0136] see Figure 7 , Figure 7 The SEM scanning electron micrograph of the surface morphology of the ZnMgO thin film prepared in Example 2 of the present invention.

[0137] Depend on Figure 7 It can be seen that the ZnMgO thin film prepared b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com