A kind of preparation method of isopropyl acetate

A technology of isopropyl acetate and acetic acid, which is applied in the field of preparation of isopropyl acetate, can solve the problems of high separation energy consumption and complicated separation process, and achieve the effects of simplifying the process, reducing production costs, and saving device energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

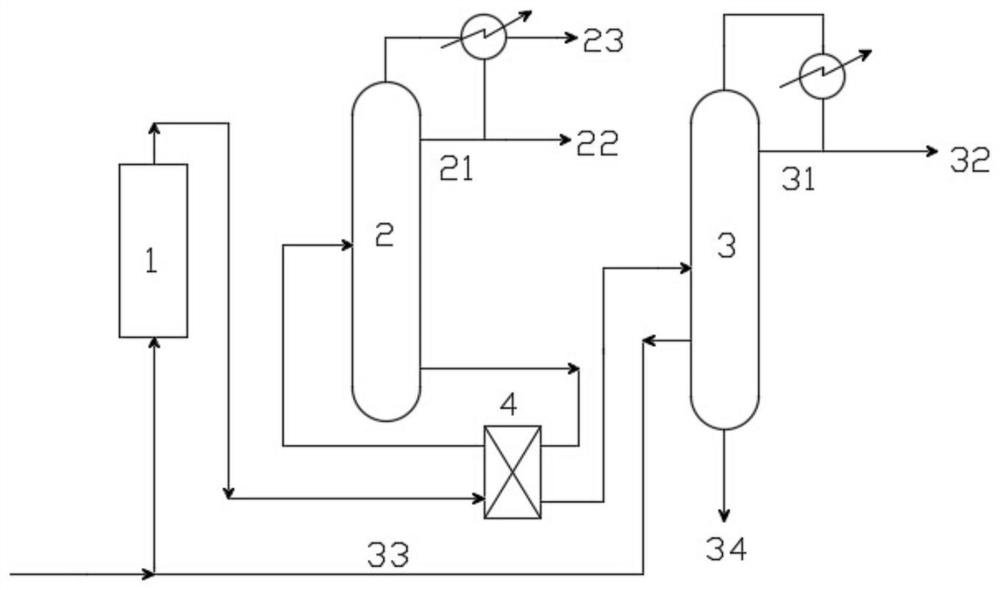

Image

Examples

Embodiment 1

[0043] Propylene (90.7% by weight of propylene, 9.3% by weight of propane) and acetic acid raw materials are mixed and added to a fixed-bed reactor, and isopropyl acetate is synthesized under the action of a cation exchange resin catalyst. The reaction conditions are: reaction temperature 30°C, reaction The pressure is 0.5 MPa, and the molar ratio of acetic acid to propylene is 1.0. After the reaction mixture is preheated, it is sent to the light removal tower for separation. The operating conditions of the light removal tower are: the temperature at the top of the light removal tower is 140°C, the pressure at the top of the tower is 0.65MPa, the temperature at the bottom of the tower is 175°C, and the pressure at the bottom of the tower is 0.66MPa. After the tower top gas phase is extracted and condensed, the isopropyl acetate is fully refluxed into the light removal tower to remove condensed water, and the unreacted propylene and propane are discharged in the form of non-cond...

Embodiment 2

[0045] Propylene (93.51% by weight of propylene, 4.06% by weight of propane, 1.51% by weight of ethane, and 0.92% by weight of butane) is mixed with acetic acid raw materials into a fixed-bed reactor, and synthesized under the action of a heteropolyacid resin catalyst Isopropyl acetate, the reaction conditions are: reaction temperature 110°C, reaction pressure 2.5MPa, molar ratio of acetic acid to propylene is 10.0. After the reaction mixture is preheated, it is sent to the light removal tower for separation. The operating conditions of the light removal tower are: the temperature at the top of the light removal tower is 110°C, the pressure at the top of the tower is 0.35MPa, the temperature at the bottom of the tower is 155°C, and the pressure at the bottom of the tower is 0.36MPa. After the tower top gas phase is extracted and condensed, the isopropyl acetate is fully refluxed into the light removal tower to remove condensed water, and the unreacted propylene, propane and eth...

Embodiment 3

[0047] Propylene (99.53% by weight of propylene, 0.47% by weight of propane) and acetic acid raw materials are mixed and added into a fixed-bed reactor, and isopropyl acetate is synthesized under the action of a cation exchange resin catalyst. The reaction conditions are: reaction temperature 50°C, reaction The pressure is 0.65MPa, and the molar ratio of acetic acid to propylene is 2.0. After the reaction mixture is preheated, it is sent to the light removal tower for separation. The operating conditions of the light removal tower are: the temperature at the top of the light removal tower is 120°C, the pressure at the top of the tower is 0.50MPa, the temperature at the bottom of the tower is 165°C, and the pressure at the bottom of the tower is 0.56MPa. After the top gas phase is extracted and condensed, the isopropyl acetate is fully refluxed into the light removal tower to remove condensed water, unreacted propylene and propane are discharged in the form of non-condensable ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com