Catalyst composition applied to olefin polymerization and olefin polymerization method

An olefin polymerization and catalyst technology, applied in the field of olefin polymerization, can solve the problems of unsatisfactory, low ethylene polymerization activity, and decreased polyethylene molecular weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

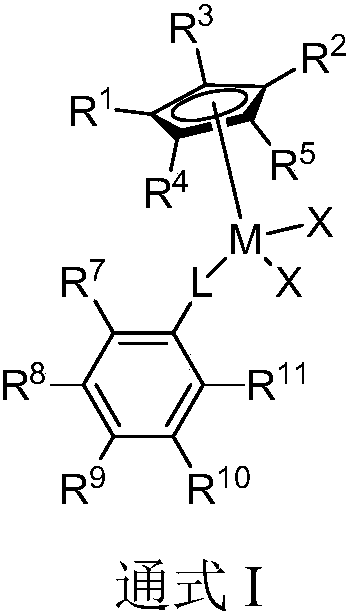

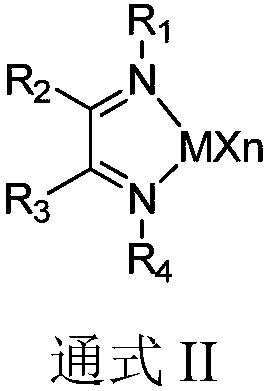

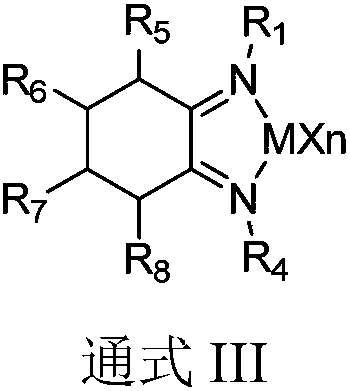

[0081] The first olefin polymerization catalyst A1 [its structure is shown in formula (1), and its synthesis process can be found in literature Organometallics, 1998, 17, 2152-2154].

[0082]

[0083] The second olefin polymerization catalyst B1 [its structure is shown in formula (2), and its synthesis process can be found in literature Macromolecules, 2009, 42, 7789-7796].

[0084]

[0085] The cocatalyst was methylaluminoxane and the shuttling agent was diethylzinc (DEZ).

[0086] The stainless steel autoclave of 1L is evacuated and replaced with nitrogen, repeats this process twice, then evacuates again, under ethylene environment, adds 500 milliliters of toluene solvents, along with the adding of toluene, the cocatalyst (6.5ml concentration is 1.53 M in methylalumoxane in toluene) and DEZ (1 ml of 1.5M DEZ in toluene) were added via syringe. Then add catalyst A1 (5ml of toluene solution with a concentration of 1.0mM) and catalyst B1 (5ml of toluene solution with a c...

Embodiment 2

[0089] The first olefin polymerization catalyst A1 and the second olefin polymerization catalyst B1 are the same as in Example 1.

[0090] The cocatalyst was methylaluminoxane and the shuttling agent was diethylzinc (DEZ).

[0091] The stainless steel autoclave of 1L is evacuated and replaced with nitrogen, repeats this process twice, then evacuates again, under ethylene environment, adds 500 milliliters of toluene solvents, along with the adding of toluene, the cocatalyst (6.5ml concentration is 1.53 M in methylalumoxane in toluene) and DEZ (1 ml of 1.5M DEZ in toluene) were added via syringe. Then add catalyst A1 (6ml of toluene solution with a concentration of 1.0mM) and catalyst B1 (4ml of toluene solution with a concentration of 1.0mM) through a syringe, continue to feed ethylene, raise and maintain the pressure to 1.0MPa, polymerize at 60°C for 30min, Cool down, collect the polymer, and weigh it.

[0092] The specific aggregation results are listed in Table 1.

Embodiment 3

[0094] The first olefin polymerization catalyst A1 and the second olefin polymerization catalyst B1 are the same as in Example 1.

[0095] The cocatalyst was methylaluminoxane and the shuttling agent was diethylzinc (DEZ).

[0096] The stainless steel autoclave of 1L is evacuated and replaced with nitrogen, repeats this process twice, then evacuates again, under ethylene environment, adds 500 milliliters of toluene solvents, along with the adding of toluene, the cocatalyst (6.5ml concentration is 1.53 M in methylalumoxane in toluene) and DEZ (1 ml of 1.5M DEZ in toluene) were added via syringe. Add catalyst A1 (2ml of toluene solution with a concentration of 1.0mM) and catalyst B1 (8ml of toluene solution with a concentration of 1.0mM) through a syringe, continue to feed ethylene, raise and maintain the pressure to 1.0MPa, and polymerize at 60°C for 30min, Cool down, collect the polymer, and weigh it.

[0097] The specific aggregation results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com