Epoxy resin production system

A production system, epoxy resin technology, applied in mixers, transportation and packaging, chemical/physical/physicochemical fixed reactors, etc., can solve the inconvenience of granulator granulation, inconvenience for customers, and epoxy resin output low level problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

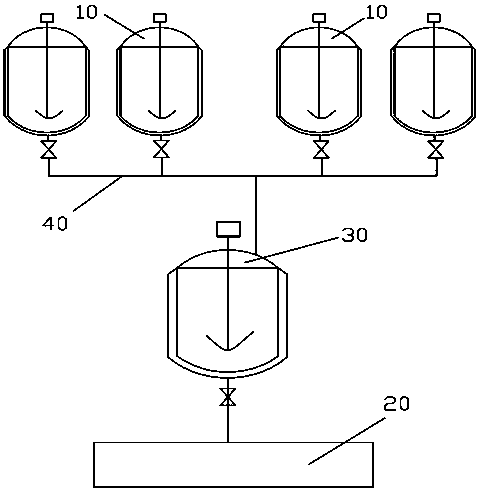

[0007] As shown in Figure 1, the production system of the present invention includes a reactor 10 and a granulator 20, a mixing tank 30 is arranged between the reactor 10 and the granulator 20, and the feed port of the mixing tank 30 is connected to a plurality of reactors The outlets of 10 are connected by pipeline 40 , and the outlet of mixing kettle 30 is connected with granulator 20 . Such a production system is provided with a mixing tank 30 between the reactor 10 and the granulator 20 in the epoxy resin production line, so that the epoxy resin produced in each reactor 10 is stirred and mixed in the mixing tank 30, Makes the quality uniform, thereby improving the quality uniformity of the finished epoxy resin. In addition, due to the addition of the mixing kettle 30, the epoxy resin in each reaction kettle 10 can be concentrated in the mixing kettle 30, so that granulation can be concentrated, and it is not necessary to equip each reaction kettle 10 with an independent gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com